Igama lephrojekthi: Ilabhulali ye-stereoscopic ezenzakalelayo (as/rs)

Isikhathi sokuqala kwephrojekthi: ekuqaleni kuka-Ephreli 2022

Isikhathi sokuphothula iphrojekthi: maphakathi noJuni 2022

Indawo yokwakha iphrojekthi: Yancheng, Jiangsu, East China

Uzakwethu wephrojekthi: inkampani entsha yokukhiqiza ibhethri lamandla Co., Ltd. e-Yancheng, Jiangsu

Isidingo samakhasimende: ibhizinisi yinkampani entsha yokukhiqiza ibhethri lamandla. Indawo yokugcina impahla yenkampani isetshenziswa kakhulu ukugcina ezinye izinto ezidingekayo ekwenzeni amabhethri e-lithium nezinye izinto zokubumba. Inqubo yokukhiqiza amabhethri e-lithium inzima futhi idinga izinto eziningi, okusho ukuthi ukusetshenziswa komsebenzi wezandla kudinga umsebenzi omningi, futhi ukusebenza kahle komsebenzi wezandla akukwazi ukuhlangabezana nezindinganiso zebhizinisi. Mayelana nalokhu, ukuze kuthuthukiswe isimo sangaphakathi seshede futhi kuncishiswe abasebenzi endaweni yokugcina izinto ngangokunokwenzeka, ukuze kwehliswe izindleko zebhizinisi, ikhasimende lithole imikhiqizo yethu yensimbi ye-Hebei Walker Co., Ltd. (umkhiqizo ozimele: i-hegris hegerls) futhi sethemba ukuthi inkampani yethu inganikeza izinsiza zendawo eyodwa ezifana nokuklama, ukwakhiwa, ukukhiqizwa, ukukhiqiza kanye nokwakhiwa kwendawo yokugcina impahla yenkampani ngokuvumelana nezidingo zabo.

Ukuqaliswa kwephrojekthi: ikhasimende libe nombono oyisisekelo kanye nesiqondiso lapho lithola inkampani yethu. Ngemva kokuxhumana nenkampani yethu, futhi ukuze kuhlangatshezwane namazinga alindelwe ikhasimende ngangokunokwenzeka, inkampani yethu yahlela ochwepheshe abangochwepheshe ukuba bavakashele enye inkampani. Ngemuva kophenyo, sithole ukuthi inkampani inenani elikhulu lezinto zokwakha kanye neshede elikhulu. Ukuze kuncishiswe kangcono ukusetshenziswa kwezisebenzi, ekugcineni sakha uhlelo lokuklama olucacile. Uhlelo lulonke lumi kanje: wonke umtapo wezincwadi ohlakaniphile onezinhlangothi ezintathu ezishintshayo udinga ukusungula imitapo yolwazi emine, okungukuthi, umtapo wezincwadi we-platinum, umtapo wolwazi wezingxenye zesakhiwo, umtapo wolwazi wokuzikhulula kanye nomtapo wolwazi wokuhlola. Umtapo wezincwadi wezingxenye zesakhiwo udinga ukuklanywa futhi wakhiwe njengamathaneli amane, futhi umtapo wezincwadi we-platinum udinga ukusebenzisa amathaneli amabili. Ngesikhathi esifanayo, uma kucatshangelwa ubukhulu bendawo yokugcina izinto, inkampani yethu ihlele ukusebenzisa amaqembu amaningi amashalofu aphakeme kakhulu, ama-stacker amaningi anezinhlangothi ezintathu zokuthatha nokubeka amasistimu, amasistimu okuphatha okuzenzakalelayo e-AGV kanye nezinye izinto ezisekelayo zokugcina nezinsiza, ukuze kuqinisekiswe ukuthi indawo yokugcina impahla ingakhulisa ukusetshenziswa kwayo kwendawo.

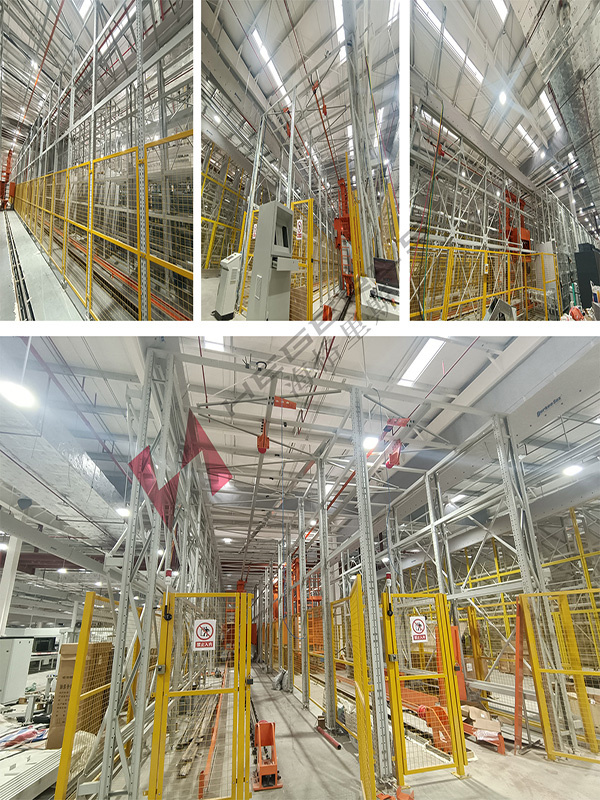

Isifinyezo sephrojekthi: i-as/rs iphrojekthi enkulu kakhulu, futhi izidingo zemininingwane ekufakweni nazo ziqinile kakhulu. Kusukela ekuqaleni kokufakwa kuya ekusetshenzisweni kwakamuva, ochwepheshe bethu banomthwalo wemfanelo mathupha wokulandelela nokuhlola iphrojekthi ye-as/rs yomtapo wolwazi ohlakaniphile ozenzakalelayo wobude obuthathu isikhathi esingaphezu kwezinyanga ezimbili. Njengamanje, isetshenziswe ngokusemthethweni futhi yaqedwa ngempumelelo ukwamukelwa. Ngesikhathi esifanayo, ithole ukwaneliseka okuphezulu kakhulu ekuhlangenwe nakho kwakamuva kwamakhasimende.

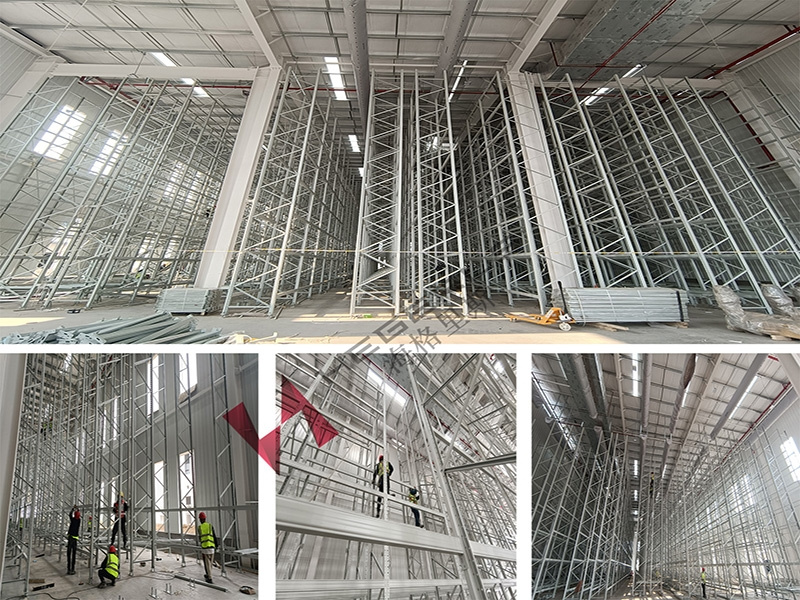

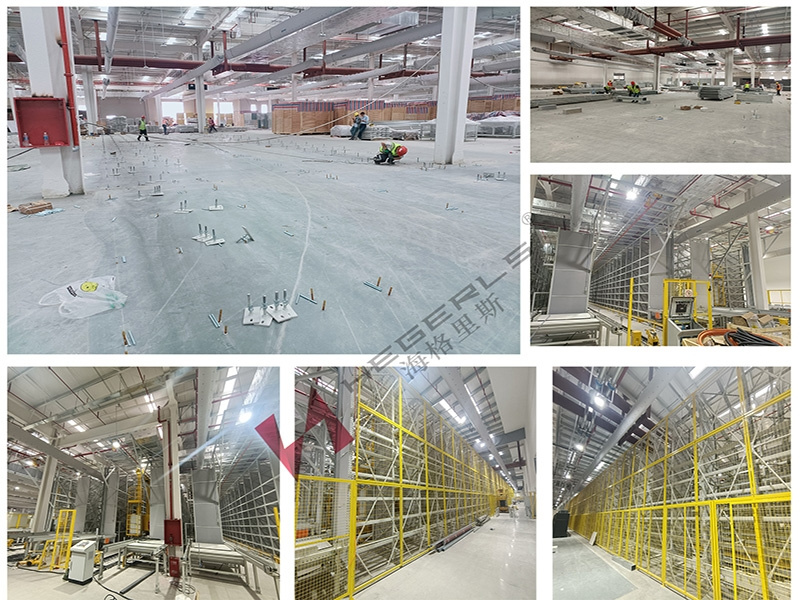

Inqubo yokuqaliswa kwephrojekthi:

Ngokukhula okukhulu kwemboni yamandla entsha, isidingo samabhethri amandla amasha siyenyuka, futhi nezindleko nokusebenza nezimfuneko ziyakhuphuka. Imboni entsha yamandla igcwele amathuba nezinselele. Ikakhulukazi, izinga lokuzenzakalela kanye nobuhlakani bemigqa yokukhiqiza ibhethri inquma ngokuqondile ukuncintisana kwamabhizinisi amasha wamandla. Ngakho-ke, ukuthuthukiswa kwemishini ezishintshayo sekuyindlela kuphela yokuthuthukisa ukuncintisana kwamabhizinisi amasha wamandla. Manje imboni iyathuthuka ngendlela yokuphepha kanye nokumiswa. Ukunemba okuphezulu, ukusebenza kahle okuphezulu, ukwenziwa kwe-serialization kanye nemigqa yokukhiqiza ezenzakalelayo ephezulu yemishini isiphenduke inkomba ejwayelekile yentuthuko. Imishini yokukhiqiza ezenzakalelayo ngokugcwele futhi ehlakaniphile izoqinisekisa ukungaguquguquki okuphezulu, ukwethembeka okuphezulu, ukuphepha kanye nokuqondile ngokusebenzisa umkhiqizo wemikhiqizo ngesisekelo sokuqinisekisa inqubo yokukhiqiza, ukuze kwenziwe ngcono izinzuzo eziphelele zebhizinisi. Phakathi kwazo, i-automated-dimensional warehouse, njengendawo yesimanje yezokuthutha, ngokungangabazeki idlala indima ebalulekile ekuthuthukiseni izinga le-automation yesitoreji samabhizinisi. Njengalokhu, i-Hebei hegris hegerls warehouse ihlongoza ukuthi kusetshenziswe indawo yokugcina impahla ehlakaniphile enezinhlangothi ezintathu ngokwezidingo zamakhasimende eYancheng, eJiangsu!

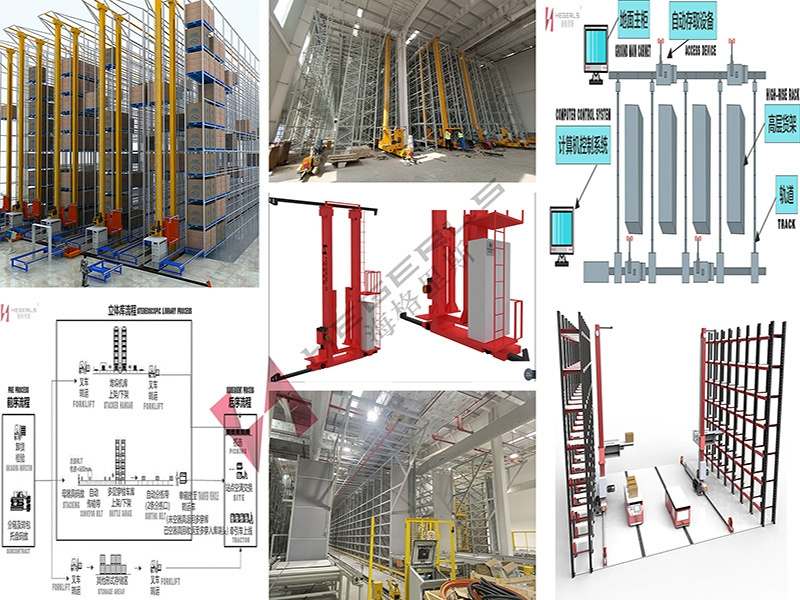

Umtapo wezincwadi we-stereo ozenzakalelayo njengo/rs umsebenzi

I-Intelligent automatic stereoscopic warehouse njengoba/rs ingagcina izinhlobo ezahlukene zezinto ngendlela efanele nangendlela ephusile ngaphansi komyalo ophezulu wesistimu yokuphatha ikhompuyutha; Nikeza zonke izinto kuyo yonke iminyango ngokunembayo, ngesikhathi sangempela nangokuvumelana nezimo, futhi unikeze ulwazi olunembile lokuthengwa kwezinto ezibonakalayo, ukuhlela ukukhiqiza, ukuhlela, ukukhiqiza nokuxhumana kokumaketha, njll. Ngesikhathi esifanayo, i-warehouse enezinhlangothi ezintathu ezizenzakalelayo nayo inemisebenzi ukonga umhlaba, ukunciphisa amandla okusebenza, ukuthuthukisa ukusebenza kahle kwamabhizinisi, ukunciphisa ukulahlekelwa kwesitoreji nezokuhamba, nokunciphisa izindleko zokuhamba.

Ilabhulali ehlakaniphile ye-stereoscopic njengoku/rs ukuhamba komsebenzi

Inqubo yokusebenza yendawo yokugcina impahla enezinhlangothi ezintathu ezizenzakalelayo ethuthukisiwe futhi yakhiwa i-Hebei hegris hegerls storage ye-energy battery manufacturer Co., Ltd. e-Yancheng, esifundazweni sase-Jiangsu imi kanje:

1 inqubo yokugcina impahla

Indawo yokugcina impahla ihlinzekwa ngetheminali yokugcina impahla endaweni ngayinye yokugcina impahla kanye nesiteji sokugcina impahla esiqediwe endaweni ngayinye ewela umzila. Ukuze imikhiqizo eqediwe igcinwe, abasebenzi basetheminali egciniwe bazobhala igama, imininingwane, imodeli kanye nenani lezinto, bese uhlelo lokulawula luzothola idatha egciniwe ngokusebenzisa isixhumi esibonakalayo sekhompyutha yomuntu. Ngokwemigomo yokusabalalisa okufanayo, okokuqala phansi, bese phezulu, kusindayo futhi kulula phansi, kugcinwe eduze kanye nesigaba se-ABC, isibali sokuphatha sizokwaba ngokuzenzakalelayo indawo yokugcina futhi sitshele umzila ogciniwe. Ngokusho kwe-prompt, abasebenzi bangathumela izinto ezilayishwe ku-pallet evamile endaweni yokugcina indawo yomgwaqo iloli elincane lebhethri lemishini yokusekela kanye nezinsiza; Imonitha iyalela isitaki ukuthi sigcine amaphalethi endaweni ebekiwe.

Qaphela: kunezinhlobo ezimbili zesitoko ekucutshungulweni kwedatha yokusungula: okokuqala, abasebenzi kufanele bafake igama (noma ikhodi), imodeli, ukucaciswa, inani, isitoko esikhona, iyunithi yokukhiqiza kanye nolunye ulwazi esitokweni esikuthreyini esitokweni. kuklayenti ngokusebenzisa isixhumi esibonakalayo sekhompuyutha yomuntu ngemva kokuba isitokwe sezimpahla; Okwesibili ukugcinwa kwempahla ngokusebenzisa ama-pallets.

2 inqubo yokulethwa

Isiphetho esingezansi yindawo yokulethwa komkhiqizo oqediwe. Igumbi lokulawula elimaphakathi kanye netheminali ifakwe amatheminali okudiliva ngokulandelana kwawo. Izikrini zokubonisa ze-LED zisethwa ezimpambanweni zomgwaqo ngamunye ukuze kwaziswe inombolo yokuphuma yezimpahla okufanele zilethwe endaweni yomhlangano. Ukuze imikhiqizo eqediwe ilethwe endaweni yokugcina impahla, ngemuva kohlobo lwabasebenzi egameni lomkhiqizo, ukucaciswa, imodeli kanye nenani, uhlelo lokulawula luzothola amaphalethi ahlangabezana nezimo zokulethwa futhi abe nenani elifanayo noma elithe xaxa ngokwemigomo. okokuqala ngqa, ukulethwa okuseduze kanye nokulethwa kuqala, lungisa idatha ye-akhawunti ehambisanayo, futhi ngokuzenzakalelayo uthumele zonke izinhlobo zamaphalethi omkhiqizo oqediwe kudeski lokulethwa ekungeneni komzila ngamunye, azokhishwa iloli yebhethri futhi alethwe endaweni okuyiwa kuyo. . Ngesikhathi esifanayo, uhlelo lokukhishwa lukhiqiza idokhumenti yenkinga kuklayenti ngemva kokuqeda umsebenzi wokukhishwa.

3. Ukucutshungulwa kokugeleza kwediski elingenalutho kubuyiselwe endaweni yokugcina impahla

Ngemva kokuba amanye amaphalethi angenalutho asuka phansi apakishwe ngesandla, abasebenzi bathayipha umyalo ongenalutho wokubuyisela i-pallet, bese abasebenzi bewathumela eNdleleni ethile ewela phansi neloli yebhethri ngokuvumelana nokwaziswa. Isitaki sizobuyisela ngokuzenzakalela amaphalethi angenalutho emnyango wangempela wendlu yokugcina impahla enezinhlangothi ezintathu, bese ishabhu ngayinye izokhipha amaphalethi angenalutho ukuze enze inzuzo ethile.

Umtapo wezincwadi ohlakaniphile ozenzakalelayo we-stereoscopic as/rs uhlome kakhulu ngezinto zokusebenza nezinsiza

Ithreyi elingu-1

Zonke izimpahla zisebenzisa amaphalethi ahlanganisiwe najwayelekile ukuze kuthuthukiswe ukushintshashintsha nokunciphisa okubekwe eceleni. I-pallet ingahlangabezana nokulayishwa nokulayishwa kwe-stacker, i-forklift nezinye izinto zokusebenza, futhi ingahlangabezana nokusebenza ku-conveyor.

2 ishalofu eliphezulu

Amashalofu aphakeme kakhulu athatha amashalofu akhethekile ahlanganisiwe kanye nesakhiwo se-beam. Isakhiwo seshalofu sihle futhi siyaphana, silondoloza izinto ezibonakalayo futhi siyasebenza, futhi kulula ukusifaka nokwakha. Kungokwesakhiwo esithuthukisiwe somklamo.

3 isitaki somgwaqo

Ngokwezici zendawo yokugcina izimpahla yenkampani entsha yokukhiqiza ibhethri lamandla, Ltd. e-Yancheng, eSifundazweni sase-Jiangsu, isitaki samukela isakhiwo sokusekela esiphansi, idrayivu ephansi kanye namakholomu amabili aseceleni. Isitaki sisebenza ezindleleni ezintathu ezididiyelwe zika-X, y kanye no-Z endleleni yeshalofu elinezitezi eziphakeme, sigcina imikhiqizo etholakala endaweni yokugcina impahla kumzila ngamunye wokungena kugridi yezimpahla ezimisiwe, noma sithutha izimpahla kugridi yezimpahla. aphumele endaweni yokubeka impahla emnyango womzila. Ukuklama nokukhiqizwa kokuhamba kwe-stacking okusetshenziswe ama-hegerls kwenziwa ngokuhambisana ngokuqinile nezindinganiso zikazwelonke, futhi amandla esakhiwo nokuqina kubalwa ngokunembile ukuze kuqinisekiswe ukusebenza okubushelelezi, okuguquguqukayo nokuphephile komshini. I-stacker efakwe ama-hegerls inendlela yokusebenza ephephile ukuvimbela ukwenzeka kwezenzakalo zengozi. Isivinini sokusebenza singu-4-80mm/min (ukulawulwa kwesivinini esishintshashintshayo), isivinini sokuphakamisa singu-3/16mm/min (injini yejubane emibili), ijubane lemfoloko ngu-2-15mm/min (ukulawulwa kwesivinini esishintshashintshayo), isiqondiso sokuxhumana. i-infrared, futhi imodi ye-elekthronikhi iyimodi yocingo olushelelayo.

4 Ukuphathwa kwekhompyutha, ukuqapha kanye nohlelo lokuthumela

Ukuphathwa kwamakhompiyutha, ukuqapha nokuthunyelwa kwesistimu kungakwaba futhi kungene ngokufanelekile yonke imisebenzi yokugcina impahla ye-warehouse enezinhlangothi ezintathu ezizenzakalelayo, futhi yenze ukuhlaziya kwezibalo zedatha yayo, ukuze kubonakale ukulawula okukhethekile kokuphathekayo, ukunciphisa umsebenzi wokusungula kanye capital, futhi kusheshiswe inzuzo yemali. Emsebenzini wokufinyelela wansuku zonke, ikakhulukazi ekusebenzeni kokukhetha ngaphandle kwendawo, akunakugwenywa ukuthi kuzoba namaphutha okufinyelela kwe-athikili, ngakho-ke ukusungula kufanele kwenziwe njalo. Ukucutshungulwa kohlu kuqinisekisa ukunemba kwedatha yento yohlu ngohlu lwangempela lwepheya ngayinye yezinto, futhi kulungisa ngesikhathi ama-akhawunti ohlu ukuze kufinyelelwe ukuhlanganiswa kwama-akhawunti nezinto zokusebenza. Isitaki ngeke senze ezinye izinhlobo zokusebenza phakathi nesikhathi sokufakwa kwempahla. Ngesikhathi sokusebenza, isitaki sizokhipha i-oda eliphelele le-inventory ku-stacker endleleni ethile yomgwaqo, futhi isitaki sizohambisa izimpahla kulo mgwaqo ukuya ngaphandle komgwaqo ngamunye ngokulandelana. Izimpahla ngeke zilayishwe ku-stacker. Ngemva kokuthola i-oda lokubuyela endaweni yokugcina impahla, isitaki sizobuyisela leli threyi lezimpahla endaweni yalo yokuqala bese sikhipha ithreyi elilandelayo lezimpahla, futhi silisunduze ngale ndlela kuze kubalwe zonke izinto zethreyi kulo mgwaqo, Noma faka. isimo esivamile sokusebenza ngemva kokuthola umyalo wokumiswa kwe-inventory ohlelweni lokuphatha. Uma umzila uthola umyalo wendawo yokuhlala yesikhashana ngaphambi kokuba uhlu luqedwe, qhubeka nokuqedela umsebenzi wokusungula ngemva kokuthola umyalo omusha.

Umthelela wohlelo lwephrojekthi:

1) Ngokusekelwe ezifundeni ezincane, ukuphathwa kokuthunyelwa kwezinto ezisetshenziswayo embonini yamandla entsha kwenziwe;

2) Ihlanganisa ngokuphumelelayo izinsiza zokugcina futhi ithuthukise izinga lokuphatha lokugcinwa kwebhizinisi;

3) I-stacker ye-multilane ehlanjululwe + ukuphatha okuzenzakalelayo kwe-agv, eqaphela isitoreji esinganamuntu;

I-4) Ukuhlanganisa ukuguquguquka nokuguquguquka, yakhe indawo yokugcina impahla ehlangabezana nezidingo zemboni entsha yamandla.

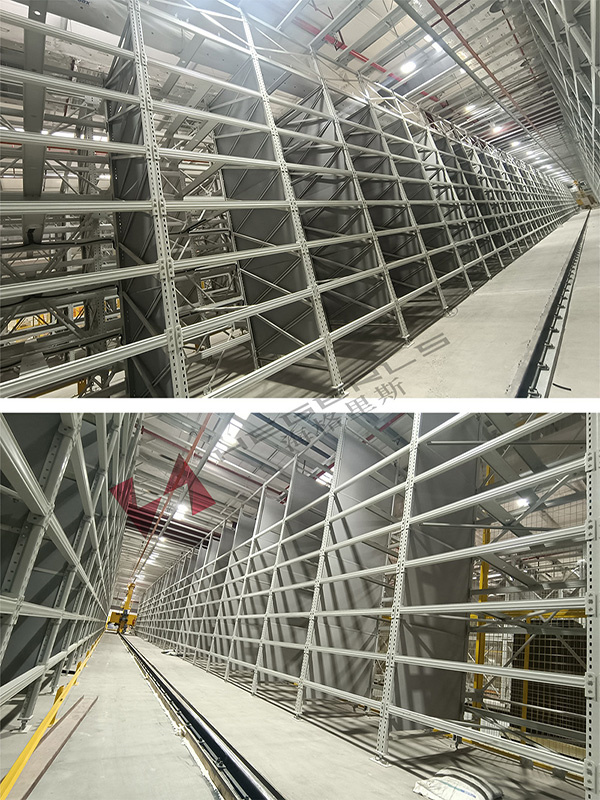

Ukuthwebula izithombe zesakhiwo sephrojekthi:

Isikhathi sokuthumela: Jun-24-2022