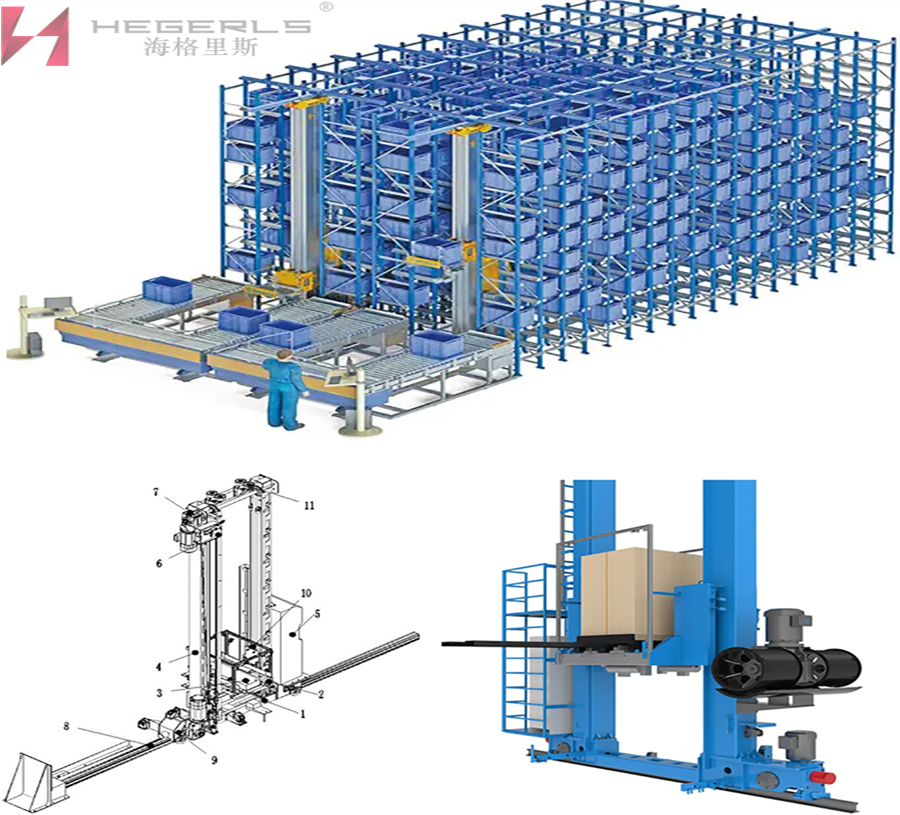

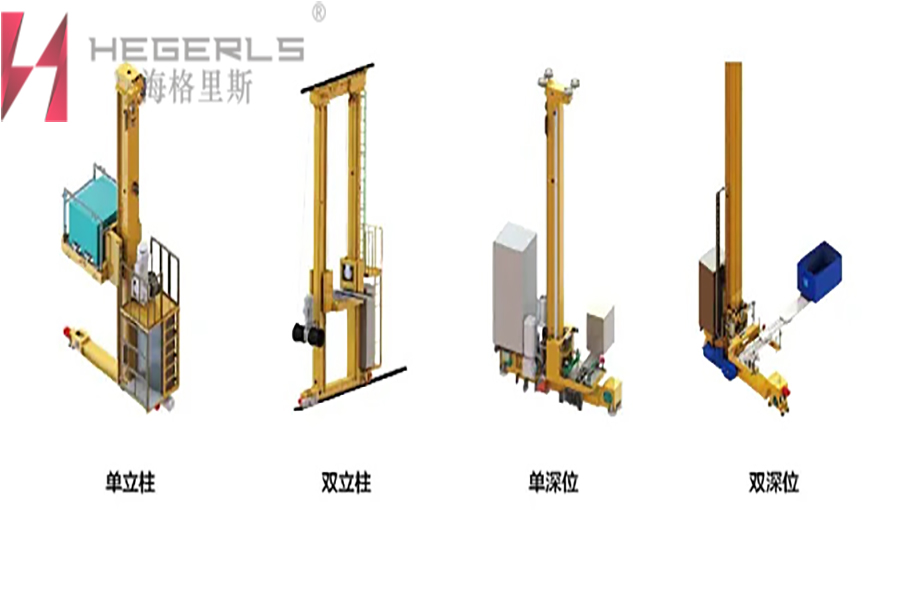

I-As / RS warehouse iyingxenye ebalulekile yesistimu yesimanje yezinto zokusebenza kanye nesistimu yokugcina ephezulu yokugcina izendlalelo eziningi kanye nokutholwa, okuhlanganisa uhlelo lokulawula indawo yokugcina impahla, amashalofu, amarobhothi, izitaki kanye nezimoto zokuthutha. Ngaphansi kokuphathwa kwesistimu yekhompyutha ye-WMS, indawo yokugcina impahla ingakwazi ukubona ukugcinwa kwempahla okuzenzakalelayo futhi ibone ukuxhumana nesistimu yokuphatha, okungokwezinyathelo zokuphatha zesimanje. Isitaki siyisisetshenziswa esibaluleke kakhulu sokuphakamisa nezokuthutha endaweni yokugcina izinto enezinhlangothi ezintathu kanye nophawu olumelela izici zendlu yokugcina izinto enezinhlangothi ezintathu. Inhloso yawo eyinhloko ukusebenza emseleni wendawo yokugcina impahla enezinhlangothi ezintathu, ukugcina izimpahla emzileni owela umugqa wezimpahla, noma ukukhipha izimpahla kugridi yezimpahla bese uzihambisa endaweni yokuwela umzila.

Ukwakheka kwesakhiwo se-stacker kuhlanganisa: ithrekhi ephansi, ujantshi womhlahlandlela ongaphezulu, iplathifomu yempahla, iphaneli yokusebenza kanye nenjini yokuphakamisa, kanye nesitaki sixhunywe nohlelo lokuphatha olungaphezulu kanye nesistimu yokulawula ukuze kuqashwe ukuzenzela kwezimpahla ngaphakathi nangaphandle kweshede. Imodi yokuxhumana ye-infrared yamukelwa kushelufu esitaki kanye nezinhlangothi ezintathu. Asikho isidingo sokuhlela izintambo eziningi kakhulu phakathi kwama-workshops, anekhono eliqinile lokulwa nokuphazamiseka. I-single chip microcomputer ingeyesistimu yokulawula yesikhungo sokulinganisa nokulawula, engakhipha iziyalezo zokuphendula ngesikhathi kukhompyutha yokuphatha ephezulu futhi isungule ukuxhumana nekhompyutha ephezulu ngesikhathi esifushane.

Yiqiniso, esimweni sokuthuthuka okusheshayo kwezenhlalakahle nezomnotho, amabhizinisi azokhathazeka kakhulu ngokuthi ngaphansi kwezidingo zokusebenza kahle kakhulu, indawo yokugcina impahla yendabuko ngeke isakwazi ukuhlangabezana nezidingo, kodwa ukusetshenziswa kwe-stacker ku-othomathikhi ye-auto-dimensional warehouse idlala indima ebalulekile. indima ebalulekile. Mayelana nalokhu, umenzi weshalofu lokugcina i-Hercules Hergels uzogxila ezinkingeni ezenzeke ekusetshenzisweni kwe-stacker, futhi abeke phambili izixazululo zalezi zinkinga.

Yiqiniso, esimweni sokuthuthuka okusheshayo kwezenhlalakahle nezomnotho, amabhizinisi azokhathazeka kakhulu ngokuthi ngaphansi kwezidingo zokusebenza kahle kakhulu, indawo yokugcina impahla yendabuko ngeke isakwazi ukuhlangabezana nezidingo, kodwa ukusetshenziswa kwe-stacker ku-othomathikhi ye-auto-dimensional warehouse idlala indima ebalulekile. indima ebalulekile. Mayelana nalokhu, umenzi weshalofu lokugcina i-Hercules Hergels uzogxila ezinkingeni ezenzeke ekusetshenzisweni kwe-stacker, futhi abeke phambili izixazululo zalezi zinkinga.

Amaphutha ajwayelekile kanye nezindlela zokunakekela ze-stacker

Iphutha nokungajwayelekile kwesiguquli sefrikhwensi esivundlile

Uma isiguquli sefrikhwensi esivundlile sihluleka, ikakhulukazi kungenxa yokuncipha noma ukuma kwesitaki okubangelwa (ukulayisha ngokweqile, ukwehla ngokushesha okukhulu, njll.).

Isixazululo sokulungisa siwukuthi: isitaki singabuyiselwa endaweni yokuqala, esimweni sokungalayishwa kanye nesinembile sokuma, bese sisethwa kabusha.

Iphutha lokuma elivundlile elingavamile

Kuyini ukungazinzi okuvundlile? Ngamanye amazwi, iyehluleka ukugijimela endaweni yokuma phakathi nesikhathi esibekiwe noma izikhathi.

Isixazululo sokulungisa siwukuthi: ingaqhubeka nokusebenza ngemva kokuthi isethwe kabusha ngezikhathi ezithile; Kodwa-ke, uma kwenzeka kwenzeka ngokuqhubekayo, kuyadingeka ukuhlola ibhuleki lokubamba noma ithrekhi yemoto evundlile.

Iphutha lekhodi evundlile elingavamile

Iphutha elingavamile lesishumeki esivundlile empeleni lisho ukuthi ukufundwa kwesifaki khodi esivundlile akulungile.

Isixazululo sokulungisa sithi: uma ikhodi yeleveli ingajwayelekile ngezikhathi ezithile, ingasethwa kabusha futhi iqhubeke nokusebenza; Uma kwenzeka okuqhubekayo, kuyadingeka ukuhlola ukuthi isifaki khodi sikhululekile, bese siqhuba ukufundisa futhi ngemva kokuhlolwa.

Ukwehluleka kwezinga lokufundisa kanye nephutha elingavamile

Ukufundisa okuvundlile kwehluleka, okungukuthi, inani lamakholomu lapho lifika ekugcineni ngesikhathi sokufundisa alihambisani nekholomu enkulu enikeziwe.

Isixazululo sesondlo ukuphinda ukufundisa noma ukuhlola ukuthi inombolo enikeziwe yamakholomu ilungile yini.

Iphutha nokungajwayelekile kwesiboni sekheli sangaphambili esivundlile

Isixazululo sokulungisa sithi: uma kukhona ukwehluleka kwesiboni sekheli sangaphambili esivundlile, ungabheka ulayini, i-chip yokuqashelwa kwekheli, shintsha iswishi, njll.

Iphutha nokungajwayelekile kwesiboni sekheli elingemuva elivundlile

Isixazululo sokulungisa sithi: uma kwenzeka iphutha lesiboni sekheli elingemuva elivundlile, empeleni liyafana nephutha lesiboni sekheli elingemuva elivundlile. Kuyadingeka futhi ukuhlola isifunda, i-chip yokuqashelwa kwekheli, esikhundleni sokushintshwa, njll.

Iphutha lokushintsha umkhawulo wesivinini sangemuva alijwayelekile

Isixazululo sokulungisa siwukuthi: lapho ukushintsha komkhawulo wesivinini sangemuva kwehluleka, singabheka isifunda, sisuse ibhodi elikhanyayo noma sishintshe ukushintsha. Ngesikhathi esifanayo, sidinga futhi ukuhlola isifaki khodi sesitaki.

Iphutha lokushintshwa komkhawulo wesivinini sangaphambili alijwayelekile

Isixazululo sokugcinwa siwukuthi: ukwehluleka kwe-switch limit limit yangaphambili empeleni kufana nokwehluleka kwe-switch limit limit limit, okungukuthi, kuyadingeka futhi ukuhlola isifunda, ukususa ipuleti lokukhanya noma ukufaka esikhundleni sokushintsha, futhi uhlole. isifaki khodi se-stacker.

Iphutha lokushintshwa kwesiphetho sangemuva elingavamile | iphutha elingavamile leswishi yangaphambili

Isixazululo sokulungisa simi kanje: empeleni, lapho inkinobho yangemuva ihluleka futhi i-switch yangaphambili ihluleka, isisombululo sokulungisa siyafana nesokuhluleka komkhawulo wejubane elingemuva kanye nokuhluleka kokushintsha umkhawulo wejubane langaphambili. Kuyadingeka futhi ukuhlola isifunda, susa ipuleti elikhanyayo noma ushintshe iswishi, futhi uhlole isishumeki se-stacker.

Iphutha elingajwayelekile lokuhlehla lokusebenza okuvundlile

Liyini iphutha le-horizontal operation reverse? Okusho ukuthi, isiqondiso senani lokushaya kweshayela yesishumeki se-pulse esivundlile siphambene nendawo yesiginali yokunyakaza enikeziwe.

Isixazululo sokulungisa sithi: sidinga ukuhlola ukuthi imigqa engu-A no-B yesishumeki se-pulse ixhumeke ngendlela efanele, noma ukuthi ukulandelana kwesigaba sokuphakelwa kwamandla kulungile.

Iphutha alijwayelekile ngemuva kokuthi isitaki sibuyele esitimeleni sokugcina

Lapho isitaki sibuyela kukholomu yokugcina, lesi simo kungenxa yokuthi okungenani isiboni sekheli esivundlile esisodwa sesitaki sishiya isiphetho esingemuva socezu lwekheli endaweni yekholomu yokugcina.

Isixazululo sokunakekela yilesi: okudingeka sikwenze ukuhlola ibhuleki yebhendi evundlile, idivayisi yokuqaphela ikheli, ucezu lokubona ikheli, kanye nepuleti lokukhipha ukukhanya ledivayisi ngayinye ebona ikheli.

Iphutha eliphambi kwesitimela esikhulu kunazo zonke esiphambi kwesitaki alijwayelekile

Yini ephambi kwesitaki naphambi kwesitimela esikhulu kunazo zonke? Eqinisweni, kusho ukuthi okungenani isiboni sekheli esisodwa esivundlile sesitaki siphumile ekugcineni kwe-chip yokuqaphela ikheli ngaphambili.

Isixazululo sokunakekela yilesi: okufanele kwenziwe ukuhlola ibhuleki yebhendi evundlile, idivayisi yokuqaphela ikheli, ucezu lokubona ikheli, kanye nepuleti lokukhipha ukukhanya ledivayisi ngayinye eqaphela ikheli.

Iphutha lokushintsha umkhawulo wesivinini alijwayelekile

Isixazululo sesondlo sithi: empeleni, incazelo yezwi nayo iqondwa kahle. Isixazululo sokulungisa ukuhlola isekethe, ibhodi lomkhawulo wejubane bese ubuyisela iswishi.

Isivinini sesitaki siphansi kakhulu futhi asijwayelekile

Iphutha lejubane eliphansi le-stacker alivamile, okungukuthi, isitaki asikwazi ukusebenza endaweni isikhathi eside ngemva kokufaka i-chip yokuqaphela ikheli.

Isixazululo sokunakekela siwukuthi: uma iphutha elinjalo lenzeka ngendlela engavamile, okudingeka kubhekwe umshini, ithrekhi noma kwenyuswe kancane isivinini sokupaka.

Iphutha nokungajwayelekile kwekheli elivundlile

Eqinisweni, kuqondwa kahle ukuthi uma noma yisiphi isiboni sekheli esivundlile sihluleka noma sisebenza ngokuzenzakalelayo, isitaki sigijimele esitimeleni okuyiwa kuso, kodwa ingxenye yekheli ayitholakalanga ngaphakathi kwebanga elishiwo lokushaya kwenhliziyo.

Isixazululo sokulungisa sithi: lapho singasethwa kabusha ngezikhathi ezithile, singaqhubeka nokusebenza; Nokho, uma kwenzeka kwenzeka ngokuqhubekayo, kuyadingeka ukuhlola ukuthi isiboni sekheli esivundlile sijwayelekile yini.

Ukwehluleka kwezinga lokufundisa kanye nephutha elingavamile

Isixazululo sokunakekela yilesi: okungukuthi, isamba senani lamakholomu achazwe ngokuvundlile alihambisani nenani lamakholomu abalwe ukufundisa. Uma leli phutha lingajwayelekile, kuyadingeka ukuhlola inani eliphelele lamakholomu achaziwe. Ikholomu enkulu yesitaki somgwaqo singamakholomu angu-100 kanye ne-chip yokuqaphela ikheli evundlile, kanye nokuthi idivayisi yokubona ikheli iyakuzwa yini.

Iphutha lephutha lekholomu yendawo okuyiwa kuyo

Isixazululo sokulungisa sithi: okungukuthi, indawo yokusebenza yesitaki ayihambisani naleyo ekhishiwe. Ngalesi sikhathi, okudingeka kwenziwe ukuhlola ikheli lendawo yokusabalalisa, ukusula ukusebenza kanye nokusabalalisa kabusha ukusebenza.

Iphutha lesiguquli sefrikhwensi eqondile kanye nokungajwayelekile

Isixazululo sokulungisa sithi: ngakho-ke yini iphutha elingavamile lesiguquli sefrikhwensi eqondile? Eqinisweni, ukuvikelwa kwesiguquli sefrikhwensi eqondile kubangelwa ukulayisha ngokweqile noma ukwehla ngokushesha okukhulu. Isixazululo esinikezwe umkhiqizi wamashalofu esitoreji sika-Hercules Hergels ukubuyisela isitaki sibuyele endaweni yokuqala, esimweni sokungalayishi nesinembile sokuma, bese usetha kabusha.

Iphutha lokuma okume mpo elingavamile

Isixazululo sokunakekela yilesi: lokho okubizwa ngokuthi ukunemba kokuma okuqondile kusho ukuthi isitaki sidlula inani elishiwo lezikhathi ngesikhathi sokusebenza okuphindaphindiwe kokukhuphuka nokuwa kwesivinini esiphansi. Umkhiqizi weshalofu lokugcina i-Hercules uphinde wathola impendulo evela kumakhasimende asebenzisanayo ngale nkinga engajwayelekile. Ngokusekelwe eminyakeni eminingi yokuhlangenwe nakho, umenzi weshalofu lokugcina i-Hercules naye unezixazululo kule nkinga. Kuyafana nezinye zezinkinga ezingenhla. Ngokufanayo, uma kwenzeka ngezikhathi ezithile, ingasethwa kabusha ngaphambi kokuqhubeka; Kodwa-ke, uma leli phutha lenzeka ngokuqhubekayo, kuyadingeka ukuthi uhlole ibhuleki le-motor eqondile noma ithrekhi.

Iphutha lekhodi eqondile elingavamile elingavamile

Isixazululo sokulungisa sithi: leli phutha alijwayelekile, okusho ukuthi, idatha efundwa isishumeki esiqondile ayilungile. Uma lokhu kungavamile kwenzeka, noma kwenzeka ngezikhathi ezithile, kungasethwa kabusha bese kuqhubeka nokusebenza; Uma lesi simo senzeka ngokuqhubekayo, kuyadingeka ukuhlola ukuthi isifaki khodi sikhululekile, bese ufundisa futhi ngemva kokuhlolwa.

Ukwehluleka kokufundisa okuqondile kanye nephutha elingavamile

Isixazululo sokulondoloza siwukuthi: ukufundisa okuqondile kwehluleka, okungukuthi, lapho ukufundisa kufinyelela ekugcineni okuphezulu, inani lezendlalelo alihambisani nesendlalelo esiphezulu esinikeziwe; Kulesi simo, umkhiqizi weshelufu lokugcina i-hegerls le-hagris uphakamisa ukuthi inani elinikeziwe lezendlalelo lifundiswe noma lihlolwe futhi, nokuthi ingabe i-chip yokuqaphela ikheli kanye nesiboni sekheli esime mpo sesendlalelo ngasinye singayithola yini.

Iphutha lekheli eliqondile (eliphansi | phezulu) alijwayelekile

Isixazululo sesondlo siwukuthi: uma leli phutha lingavamile, kuyadingeka ukuhlola isifunda, ukususa ibhodi elikhanyayo noma ukubuyisela ukushintsha, futhi uhlole umhleli we-stacker.

Umkhawulo wejubane eliphezulu | Iphutha lokushintshwa komkhawulo wejubane eliphansi alijwayelekile

Isixazululo sokunakekela siwukuthi: umkhawulo wejubane eliphezulu kanye nokushintshwa komkhawulo wejubane ophansi akujwayelekile, okuqondwa kahle. Isixazululo ukuhlola ngokuqondile isifunda, susa ipuleti elikhanyayo noma ushintshe iswishi. Impela, isifaki khodi sesitaki kufanele futhi sihlolwe ngesikhathi esifanayo.

Iphutha elingajwayelekile lokuhlehla lokusebenza okuqondile

Isixazululo sokulungisa sithi: leli phutha ukuthi isiqondiso senani lokushaya kwe-pulse ye-vertical pulse encoder iphambene nesiqondiso sesignali enikeziwe yokunyakaza; Ngesikhathi sokulungiswa kwayo, abasebenzi bazohlola ukuthi imigqa engu-A no-B yesishumeki se-pulse ixhumeke ngendlela efanele, noma ukuthi ukulandelana kwesigaba sokuphakelwa kwamandla kulungile.

Iphutha lokuvikela ukuxegiswa kwentambo lomlawuli wejubane alijwayelekile

Isixazululo sesondlo yilesi: uma kunephutha ekuvikelweni kwezintambo ezixegayo zomlawuli wejubane, qiniseka ukuthi uyabheka ukuthi intambo yensimbi yomlawuli wejubane ayikhululekile yini. Uma kunjalo, abasebenzi kudingeka bahlole futhi balungise.

Iphutha elingaphansi kwe-chip yokuqaphela ikheli lesendlalelo esiphansi kakhulu kanye nongqimba oluphakeme kakhulu lwephalethi alijwayelekile

Isixazululo sokulungisa simi kanje: empeleni, isiphetho esiphansi noma esingaphezulu sesiqephu sokuqashelwa kwekheli sivela kuwo womabili amadivaysi okubona ikheli kuplathifomu yempahla ezansi noma phezulu. Isixazululo ukuhlola ngokuqondile ibhuleki yokubamba eqondile, idivayisi yokuqaphela ikheli kanye nocezu lokubona ikheli.

Ukungajwayelekile kwephutha lesivinini esiqondile

Isixazululo sokunakekela yilesi: iphutha elishiwoyo elime mpo le-overspeed alijwayelekile, okungukuthi, isivinini sangempela esitholiwe sidlula ububanzi obushiwo besivinini esinikeziwe. Umkhiqizi weshelufu lesitoreji se-hegris hegerls uncoma ukuthi kubhekwe izintambo zemoto ezime mpo nokubamba ibhuleki.

Okuhlukile kwephutha lekheli eliqondile

Isixazululo sokulungisa simi kanje: iphutha lesiboni sekheli eliqondile alijwayelekile, okungukuthi, lapho noma yisiphi isiboni sekheli esime mpo sihluleka noma sisebenza ngokuzenzakalelayo, i-pallet iye yagijimela kungqimba lwendawo, kodwa ucezu lwekheli alutholakalanga ngaphakathi kwesibonisi esicacisiwe. ububanzi be-pulse yephutha. Okufanele ikwenze ibhizinisi ukuhlola ukuthi iswishi nesekhethi konakele yini noma ukuthi iswishi ne-chip yokuqaphela ikheli kuyasebenzisana yini.

Iphutha le-rotor ekhiyiwe ngemfoloko alijwayelekile

Isixazululo sesondlo yilesi: amabhizinisi amaningi kungenzeka ahlangabezane nale nkinga yephutha, okungukuthi, imfoloko ayinwetshwa (ihoxisiwe) endaweni phakathi nesikhathi esibekiwe. Uma le nkinga yenzeka, sidinga ukuhlola ukuthi zikhona yini izithiyo emzileni wokwandisa imfoloko noma ukuthi indlela yemfoloko ikhululekile yini; Uma ucindezela ukhiye wokusebenza Okuhlaza ukuze usule iphutha, bese ucindezela imfoloko yesandiso bese usebenza ngokuphindaphindiwe kuze kube yilapho imfoloko ima kahle.

Iphutha lokutholwa kwemfoloko ephezulu alijwayelekile

Isixazululo sesondlo yilesi: okungukuthi, lapho imfoloko inesimo esiphakathi nendawo, okungenani inkinobho eyodwa engenhla yokuthola indawo ephakathi nemfoloko ayinaso isignali, noma imfoloko engenhla ayitholi indawo ephakathi; Uma kwenzeka ukwehluleka kweswishi engenhla yokuthola imfologo, kuyadingeka ukuhlola ukuthi iswishi nesekhethi konakele yini, noma ukuthi iswishi ifaniswe nerula lomthelela. Ngesikhathi esifanayo, kuyadingeka futhi ukuhlola ukuthi imfoloko ibuyele endaweni yayo yasekuqaleni.

Iphutha le-Fork neutral stop stop alijwayelekile

Isixazululo sokulungiswa yilesi: uma iswishi ye-fork middle stop ingajwayelekile, kuyadingeka ukuhlola ukuthi iswishi nesekhethi konakele noma ukuthi iswishi kanye nerula yomthelela kuyasebenzisana.

Uphenyo lwemfoloko kwesokunxele | iphutha lokushintshwa kophenyo lwesokudla alijwayelekile

Isixazululo sokulungisa siwukuthi: uma ukushintshwa kokubona kwesokunxele noma kwesokudla kwemfoloko kwehluleka, kusho ukuthi inkinobho yokubona kwesokunxele noma kwesokudla yemfoloko ayikwazi ngokuvamile ukubona i-pallet. Ngalesi sikhathi, okudingeka sikwenze ukuhlola ukuthi iswishi nesekhethi konakele yini noma silungise ngokuqondile iphutha leswishi yokuthola.

Kwesokunxele | ukushintsha kokungajwayelekile kwephutha kokutholwa kwe-skew kwesokudla

Isixazululo sokunakekela siwukuthi: uma iswishi yesokunxele | yokutholwa kwe-skew kwesokudla ingajwayelekile, hlola ukuthi iswishi nesekhethi konakele yini nokuthi iswishi nesibonisi kuyasebenzisana.

Iswishi yokutholwa kwempahla yephalethi inephutha noma ayijwayelekile

Isixazululo sokunakekela siwukuthi: lapho ukushintshwa kokutholwa kwempahla yesikhulumi sokulayisha kunephutha elingavamile, kuyadingeka ukuhlola ukuthi ukushintshwa nokujikeleza konakele yini nokuthi ukushintshwa nesibonisi kuhambisana yini.

Ukungajwayelekile kwephutha lokuvala isikhathi sokuvala

Isixazululo sokulungisa simi kanje: lapho i-pallet ingakhuphukeli endaweni ephezulu lapho ithatha izimpahla noma ingaweli endaweni ephansi lapho igcina impahla ngesikhathi esibekiwe, abasebenzi kufanele baqale bahlole ukuthi isiboni sekheli sishintshile yini. yonakele noma ukuthi iswishi nesiboni sekheli kuyafana yini.

Iphutha lentambo yokuvikela exegayo elingavamile

Isixazululo sokunakekela yilesi: uma intambo yensimbi ixega noma iphukile, bheka ukuthi kukhona yini i-alamu engamanga bese uthinta abasebenzi bosekelo lwezobuchwepheshe.

Ukungajwayelekile kwephutha lokuvikela ukulayisha ngokweqile | iphutha lokuphakama okuphezulu kwempahla

Isixazululo sokunakekela siwukuthi: lapho izimpahla zikhuluphele noma ziphakeme kakhulu, kuyadingeka ukuhlunga impahla ngaphambi kokusebenza futhi.

Iphutha lempahla ende elingejwayelekile

Isixazululo sokulungisa simi kanje: iphutha lezimpahla ezinde ukuthi uma isitaki sikhipha izimpahla ekugcineni, sizobona ukuthi kunezimpahla ku-conveyor. Uma lesi simo senzeka, kuyadingeka ukususa izimpahla ezihambisanayo phambi komthumeli bese ucindezela inkinobho yokusetha kabusha ukuze usethe kabusha.

Iphutha lokuvikela ukushisa ngokweqile kwemfoloko alijwayelekile

Isixazululo sesondlo yilesi: Lokhu kungenxa yokuthi uma sisebenza isikhathi eside noma silayishwa ngokweqile, sizoholela ekuvikelweni kwe-thermal relay yemfoloko. Uma lokhu kwenzeka, vula ikhabhinethi yokulawula bese ucindezela othintana naye obomvu we-“fr” relay eshisayo.

Iphutha lemodi yokufundisa alijwayelekile

Isixazululo sesondlo yilesi: uma imodi yokufundisa yehluleka, isixazululo sokulungisa siwukucisha futhi uqale kabusha ngemva kokufundisa, bese ucindezela isisombululo sokusetha kabusha ukuxazulula le nkinga.

Kukhona iphutha lokusebenza elingavamile ngesikhathi sokuqalisa

Isixazululo sesondlo siwukuthi: kukhona ukusebenza ngesikhathi sokuqalisa, okungukuthi, ukusebenza okukodwa kugcinwa ngemva kokuvalwa, ngakho-ke lesi simo singasixazulula kanjani? Yebo, ungacindezela ukhiye wokusebenza ukuze usethe kabusha noma usule umsebenzi wamanje.

Iphutha le-pallet ephezulu lingena endaweni engafanele alijwayelekile

Isixazululo sesondlo siwukuthi: okuthiwa i-pallet ephezulu ingena endaweni engafanele ukuthi ukusebenza kubonisa indawo ephansi futhi izimpahla ze-pallet ziphakeme kakhulu. Kulokhu, kuyadingeka ukukhipha kabusha ukusebenza bese ulayisha kabusha izimpahla.

Iphutha lempahla engavamile / iphutha elingaphezu kobubanzi

Isixazululo sesondlo siwukuthi: izimpahla zitshekile noma zibanzi kakhulu, empeleni zibhekisela ku-skew wezimpahla ze-pallet. Uma lokhu kwenzeka, kuyadingeka ukuhlunga izimpahla ze-pallet futhi uhlole ukuthi iswishi yokuthola inephutha yini.

Ukungajwayelekile kwephutha lekhodi eyisitaki

Isixazululo sesondlo yilesi: lokho okubizwa ngokuthi ikhodi eyimpumputhe ye-stacker kusho ukuthi isithwebuli asiskeneli ibhakhodi. Isiphakamiso esinikezwe umenzi wamashalofu esitoreji sika-Hercules Hergels esokukhuhla iswishi yokuskena bese uhlola ibhakhodi.

Ukuxhumana okungajwayelekile nesithuthi

Isixazululo sokugcina siwukuthi: uma kukhona ukwehluleka kokuxhumana nomshayeli futhi umshini awukwazi ukunyakaza, into yokuqala okufanele uyihlole ukuthi ngabe umugqa uxhunyiwe.

Akukho okuhlukile kwephutha lephalethi emgqeni womsebenzi

Isixazululo sokulungisa sithi: kungenzeka ukuthi amanye amabhizinisi ahlangabezane nesimo sokuthi alikho i-pallet enjalo kulayini wokusebenza. Uma lokhu kwenzeka, bangakwazi ukukhipha i-pallet kuqala, bese bebeka i-pallet ngemva kokukhipha umsebenzi.

Iphalethi lamanje lingena emgwaqeni ongalungile, futhi iphutha alijwayelekile

Isixazululo sokugcina siwukuthi: lapho i-pallet yamanje ingena emgwaqeni ongalungile futhi ihluleka, idinga ukubeka i-pallet futhi.

Alikho iphutha noma okungajwayelekile ekucosheni

Isixazululo sokunakekela siwukubheka isimo sendawo yempahla ngqo uma icosha noma ingekho isitsha.

Iphutha eliphindwe kabili le-warehousing

Isixazululo sokunakekela siwukuthi: uma kunephutha eliphindwe kabili le-warehousing, okudingeka kwenziwe ukuhlola isimo sendawo noma ukuthola ngokuqondile iswishi.

Ukusebenza okungekho emthethweni | okuhlukile kwephutha lesendlalelo sendawo

Isixazululo sokunakekela siwukuthi: uma lezi zimo ezimbili zenzeka, okudingeka sikwenze ukuphinde sikhiphe umsebenzi.

Inombolo yethreyi engalungile, iphutha elingavamile

Isixazululo sokulungisa sithi: ngokuvamile, uma inombolo yephalethi eskeniwe ihlukile kunenombolo yephalethi yokusebenza, noma uma iphalethi ingaskenwanga, umsebenzi nawo udinga ukukhishwa kabusha.

Isikhathi sokuvala sokusebenza komthumeli | ukungajwayelekile kwephutha lokumisa isimo esiphuthumayo

Isixazululo sokulungisa siwukuthi: uma isithumeli sempahla sisebenza isikhathi esengeziwe noma kunesitobhi esiphuthumayo, mane ucindezele inkinobho yokusetha kabusha.

Ukungajwayelekile kwephutha lokuthola ukushintsha komoya

Isixazululo sokulungisa siwukuthi: uma kunephutha lokuthola ukushintshwa komoya, kuyadingeka ukuhlola ukuthi ukushintsha kanye nesekethe kujwayelekile yini.

Iphalethi ngaphakathi / ngaphandle kwephutha elihlukile

Isixazululo sokunakekela simi kanje: lapho ukungqubuzana nokwehluleka okungavamile kwe-pallet ngaphakathi nangaphandle kwe-warehouse kwenzeka, okudingeka sikwenze ukulungisa ukungena nokuphuma kwe-warehouse.

Iphutha likasayizi wephalethi alijwayelekile

Isixazululo sokulungisa sithi: uma usayizi wethreyi ungajwayelekile, vele ulungise indawo yethreyi.

Ukuphakama okuphezulu kwethreyi | ububanzi obuphezulu kwesokunxele | iphutha lephutha lobubanzi obungaphezu kwesokudla

Isixazululo sokulungisa siwukuthi: uma i-pallet inobude obukhulu, ububanzi obungakwesokunxele kwesokunxele nobubanzi obukhulu besokudla, idinga ukufaka ikhodi kabusha ngokuqondile impahla.

Ukuxhumana okungavamile nesitaki

Isixazululo sokugcina siwukuthi: uma usebenzisa i-stacker, kuzoba nokuhluleka kokuxhumana ne-stacker futhi i-pallet ngeke ihambe. Ngalesi sikhathi, yima futhi uhlole ukuthi ulayini uxhumekile yini.

Isikhathi sokuthumela: May-23-2022