Ishalofu lephalethi le-Crossbeam, elaziwa nangokuthi ishelufu elisindayo, liwuhlobo oluvame kakhulu lweshalofu elinokucosha kahle. Ngenxa yokuthi ukuminyana kwesitoreji se-rack yayo engaguquki kuphansi futhi izinto ezigciniwe zisinda, kufanele zisetshenziswe ne-pallet ne-forklift, ngakho-ke ibizwa nangokuthi i-pallet rack. Uma ukhetha amashalofu ephalethi ye-cross beam, ubukhulu, isisindo kanye nama-stackinglayers ama-pallets nezimpahla kufanele kucatshangelwe ukuze kunqunywe izinsika ezifanele futhi kulinganise ubukhulu. Ukwengeza, ukuze kuthuthukiswe izinga lokusebenzisa isikhala, ububanzi besiteshi bungancishiswa, kuhlanganiswe nefomu lethrekhi yesitaki esikhethekile ukwenza indawo yokugcina iqonde, okungukuthi, ibe irack yempahla yomzila omncane. Khona-ke lapho usebenzisa ishalofu lephalethi lendlu yokugcina impahla enzima, kufanele uqale uyiqonde. Manje ake sikuthathe sikuyise endaweni yokugcina impahla ye-hegerls ye-haggis ukuze uqonde ishalofu lephalethi lendlu yokugcina impahla enzima nokuthi isiphenduke kanjani indawo yokugcina impahla enezinhlangothi ezintathu ezizenzakalelayo emabhizinisini amaningi!

I-Hagerls ingumhlinzeki weshalofu ophelele ohlanganisa i-R & D, ukukhiqiza, ukuthengisa kanye nesevisi. Selokhu yasungulwa, inkampani ibilokhu ibambelela kumgomo wobuqotho, ikhasimende kuqala kanye nekhwalithi, futhi iye yanconywa kakhulu amakhasimende amaningi embonini. Ikakhulukazi, inkampani inabalingani besikhathi eside abanamasu emkhakheni wezokuthutha nokugcinwa kwempahla, imboni yamakhemikhali ezokwelapha, ukukhiqizwa kwezimoto, izimboni zezempi, njll. inkampani inabasebenzi abahlanu be-R & D, ikakhulukazi ukuthuthukisa ubuchwepheshe bemboni yeshalofu, ukuze kwethulwe imikhiqizo emisha ngezikhathi ezithile ukuze kuhlangatshezwane nezidingo zamakhasimende ahlukene, futhi kukhuphule amazinga okuklama nemiqondo yamashalofu iye ezingeni elisha, okuphinde kube isiqondiso sokuthuthukiswa kobuchwepheshe bethu.

I-Hegerls nayo inemishini yokukhiqiza ishalofu ephelele. Inkampani isebenzisa ngokuqinile izindinganiso zesistimu yekhwalithi ye-ISO, futhi iklama futhi ikhiqize amashalofu anamandla okuthwala, ukumelana nokugqwala, ukwakheka okunengqondo, ukuqaqa nokuhlanganisa okulula, kanye nokuhlanganiswa okungahleliwe ngokwezidingo zamakhasimende ezahlukahlukene ngesisekelo sethiyori yemishini kanye nobuchwepheshe besakhiwo sensimbi. I-Tailor yenzelwe amakhasimende ayo ukuthi alethe imiqondo yesimanje yezokuthutha. Ngokuphathwa okuphelele, amathuluzi esimanje kanye nentuthuko enesivinini esikhulu, i-hegerls iphokophele phambili ebhizinisini lesimanje lempahla nelokugcina impahla.

Ngesikhathi esifanayo, ifektri ineminyaka eminingi yokuhlangenwe nakho ekukhiqizeni, ukufakwa kanye nokuthunyelwa kwezindawo zokugcina izimpahla ezinkulu. Ngokwezidingo zekhasimende, ipulani yaphansi yendawo yokugcina impahla ingakalwa endaweni, futhi uhlelo lokulondoloza impahla oluphusile lunganikezwa ngokwezidingo zekhasimende. Ifekthri isekela izidingo zokwenza ngokwezifiso zamakhasimende. Isibonelo, umbala, usayizi, izidingo zokuthwala zengqimba ngayinye yeshalofu, njll. ubuningi bungenziwa ngendlela oyifisayo, futhi ayikho imali yokucubungula ngokwezifiso.

Izinhlobo eziningi ezahlukene zamashalofu okugcina kanye nemishini yokugcina ekhiqizwa ama-Hegels ahlukile kunezabanye abakhiqizi. Manje ake sibheke umehluko phakathi Hegels ugongolo esindayo warehouse Pallet amashalofu?

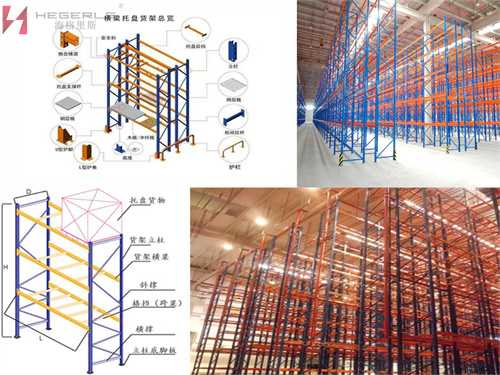

I-Hagerls - isakhiwo seshelufu se-pallet ye-cross beam

Ucezu lwekholomu: lwakhiwe ngamakholomu amabili, izisekelo eziphambanayo nezinsimbi ezinamaphiko ezixhunywe ngamabhawodi azikhiya enayiloni. Isakhiwo esihlanganisiwe sivimbela ngokuphumelelayo ukungazinzi kweshalofu okubangelwa ukukhulula ama-bolts. Amakholomu ashaywa ngemigqa emibili yezimbobo ze-rhombic, futhi i-pitch yembobo ingu-75mm noma 50mm. Ngakho-ke, ugongolo olulenga kukholamu lungalungiswa phezulu naphansi ngokukhululekile ngo-75mm noma 50mm njengendawo eyodwa. Ingxenye ephambanayo yekholomu yakhiwe ngobuso obuyi-11~13, enebanga elikhulu le-inetia, umthamo oqinile wokuthwala kanye nokumelana nomthelela onamandla. Ikholomu yeshalofu leshalofu eliphambanayo isebenzisa ubuchwepheshe bokubhoboza okuzenzakalelayo kuqala bese kulandela ukugoba okubandayo, okugwema ukwehluleka okungaba khona kokuqhekeka kwekholomu ngenxa yokugxilisa ingqondo yekholomu. Ukuze uvimbele ukushayisana kwama-forklift, amakholomu ngokuvamile ahlonyiselwe ukuvikela.

I-Crossbeam: iboshwe ngezinsimbi ezimbili zamakholomu nezinduku eziphambanayo. I-crossbeam ishiselwa yimishayo yokushisela emise okukhethekile emibili ukuze iphindwe kabili ubukhulu bezingxenye ezingaphezulu nezingezansi ze-crossbeam. Ngokusho kwe-steel structure design theory, lesi sakhiwo sisebenzisa ngokugcwele umthamo othwala umthwalo wezinto ezibonakalayo, ezinezici zesisindo sokukhanya, umthamo oqinile wokuthwala umthwalo kanye nezindleko eziphansi. Uma i-beam ixhunywe nekholomu, ifakwe iphinikhodi yokuphepha eklanywe ngokukhethekile nama-lugs. Iphinikhodi yokuphepha enama-lugs ayikwazi ukukhishwa kalula, engaqinisekisa ukuthi ugongolo ngeke liwe ngemva kokuthintwa amandla angaphandle.

I-Heigris hegerls - imininingwane yesakhiwo seshelufu enezinhlangothi ezintathu ezineshelufu lephalethi eliphambanayo

I-laminate yamandla aphezulu: ukubukeka kwenziwa nge-pickle, i-phosphating, i-othomathikhi yokufafaza umugqa wokuhlanganisa kanye nokubhaka kopende okushisa okuphezulu, okunomphumela ogqwala kakhulu;

I-Crossbeam: yamukela idizayini yembobo yehhuku, efakwe ngokunengqondo nekhithi ku-crossbeam, elungele ukuhlakazwa nokuhlanganisa. Uma kuqhathaniswa neshalofu lensimbi ye-engeli, igcina i-1/2 yesikhathi sokufaka futhi ithuthukisa kakhulu ukusebenza kahle;

Ubuchwepheshe be-Super Welding: I-brace enezinhlangothi ezintathu ezivundlile kanye ne-diagonal brace ziyashiselwa ukuze kwandiswe umthamo wokuthwala onezinhlangothi ezintathu;

Iphansi elishiselwe: thuthukisa ukungqubuzana phakathi kweshalofu nomhlabathi futhi uthuthukise ukuqina kweshalofu;

I-Crossbeam: i-crossbeam ifakwe ibhande lokuphepha ukuvimbela ukuhambisa i-crossbeam;

Izingxenye ezimise okwezitembu: izingxenye ezimise okwezimo zigoqeka ngokuzenzakalelayo yifektri yethu, futhi ukuqina kwazo namandla ahlangabezana nezindinganiso zezimboni zoMnyango Wemishini.

I-Heigris hegerls - izinto ezisizayo ze-beam pallet rack ye-three-dimensional warehouse

I-Shelving: sekela ithreyi, uqinise ukuzinza nokuphepha kwethreyi. (i-i-span beam, i-i-span beam, i-i-span beam)

Induku yokudonsa: okuhlanganisa ukudonsa emuva, ukudonsa kwesiteshi, ukudonsa odongeni, njll., ukwandisa ukuphepha nokuzinza kweshalofu.

Onogada bakhona nezithiyo zokuphahlazeka (okukodwa kokubili): vikela ikholomu ukuze uvimbele i-forklift ukuthi ingashayisi ngephutha eshalofini.

Izikhonkwane zokuphepha, ama-bolts nezinye izesekeli: zifakwe izikhonkwane zokuphepha eziphelele, ama-bolts, izikulufa zokunweba nezinye izesekeli, ezingaqinisa i-beam ukuze ziwe, futhi ziqinisekise kangcono ukusetshenziswa okuphephile kwamashalofu.

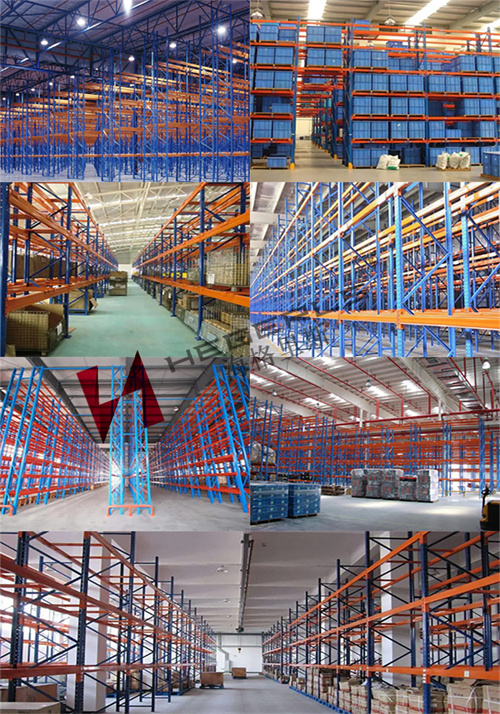

Isakhiwo se-rack ye-tray yesiphambano silula futhi sithembekile, esingalungiswa futhi sihlanganiswe ngokuthanda, futhi sinezici zomzuzu omkhulu we-inertia, umthamo oqinile wokulayisha ungqimba kanye nokumelana nomthelela onamandla. Isendlalelo ngasinye singalayishwa kuze kufike ku-5000kg/ ungqimba ngaphansi komklamo ohlobene. Ayinqunyelwe ukulandelana kwezinto ngaphakathi nangaphandle kwe-warehouse, futhi ingabunjwa ibe nkulu kakhulu. Amashalofu esikhunta, amashalofu e-attic, amashalofu e-warehouse angama-three-dimensional, njll angakhiwa futhi ngesisekelo samashalofu wethreyi, angenziwa amashalofu akhethekile emiphongo kawoyela, njll. Leli thala elisindayo lingasetshenziswa kabanzi kwimodi yokugcina i-pallet. isitoreji kanye nokufinyelela kwe-forklift. Ngokubukeka, ingakwazi ukuvimbela i-forklift ukuthi ingangqubuzani, futhi ingandisa futhi amakholomu onyawo lwekholomu kanye nezinduku zokulwa nokushayisana. Ukuze uthwale umthwalo wesendlalelo, ungaphinda ubeke ukusekelwa kwe-beam, i-laminate, i-mesh cross beam nezinye izinsiza ezihambisanayo emgqeni. Lapho amabhizinisi efaka le rack esindayo, ingathuthukisa ukuphakama kwendawo yokugcina impahla futhi ithuthukise izinga lokusebenzisa indawo yokugcina impahla. Inezinzuzo zezindleko eziphansi, ukufakwa okulula nokusebenza, kulula ukuthola indawo, ilungele amathuluzi okuphatha, futhi ifanele ukugcinwa kwezinhlobo ezahlukene zezimpahla.

Ama-Hagerls – izinzuzo zendlu yokugcina impahla enezinhlangothi ezintathu eneshalofu lephalethi le-crossbeam

Umthamo omkhulu wokuthwala kanye nevolumu elula: umthamo wokuthwala ngemitha yesikwele ngayinye ungaphezu kuka-300kg, ongahlangabezana kalula nesidingo sakho esiphezulu;

Ukuthuthukiswa kwendawo yokugcina impahla: amashalofu angahlanganiswa namashalofu amakhulu nasizayo, athuthukise kakhulu indawo yokugcina izinto, enze kube lula ukugcinwa kwempahla, ukonga imali yokuqasha kanye nokwenza ngcono ukusebenza kahle komsebenzi;

Ihlala isikhathi eside: izitolo ezinkulu, i-welding ebushelelezi futhi enhle, enokumelana nokuguga, ukumelana nokugqwala kanye nokumelana nokugqwala, ngisho nendawo engaphansi emanzi kakhulu iyasebenza;

Inqubo yokufafaza nge-Powder: ukugqoka kuminyene, ukunamathela okuhle, amandla omthelela nokuqina, ukumbozwa kwekhona eliphezulu, ukumelana nokugqwala kwamakhemikhali okuhle kakhulu, futhi kuhlala kusha isikhathi eside;

Ukwenziwa kwensimbi egoqiwe ebandayo: qinisekisa ukuthi ubukhulu bezinto ezibonakalayo bufana futhi indawo engaphezulu ayinaso isenzakalo se-concave convex;

Idizayini ye-tube yesikwele yegatsha enezingqimba ne-oblique: inani elikhulu lamagatsha avundlile lithuthukisa ukungezwani kweqembu lekholomu.

I-Hagerls - umtapo wezincwadi we-crossbeam pallet rack ungasetshenziswa ngezindlela eziningi

Ukumatanisa namaphalethi ensimbi: amaphalethi ensimbi abekwa emashalofini e-crossbeam, futhi ama-pallets ensimbi alungiswa emashalofini aphezulu ukuze agcine impahla esindayo, ephephile futhi engabizi kakhulu.

Ukumatanisa nebhokisi lempahla ye-chuanzi kanye nethreyi lepulasitiki: ungqimba lokuqala lwezimpahla lubekwe ngokuqondile phansi nebhokisi lempahla ukuze kuqinisekiswe ukuthi izimpahla azithintwa umswakama, futhi ungqimba lwesibili nolwesithathu lufakwe igridi emise okwe-I ngaphansi kwepulasitiki ye-chuanzi. ithileyi.

Ukufanisa ipuleti lensimbi: uma kucatshangelwa ukuthi izinyawo zebhokisi lezinto azikwazi ukuwela ngokunembile phezu kwe-beam, i-steel plate ibekwa phezu kwe-beam ukuze kuqinisekiswe ukuphepha.

Ngamapuleti ensimbi ashiselwe: amapuleti ensimbi angashiselwa kumagridi amabili ukuze enze imishayo yokudonsa, esetshenziselwa ukuthwala izinyawo ezine zebhokisi lempahla, elingaqinisekisi nje kuphela ukuthi ibhokisi lempahla lingawela ngokuphephile eshalofini, kodwa futhi longa izindleko. .

Ukumatanisa nephalethi yokhuni enezinhlangothi ezimbili: indawo ephakeme engu-6m ehlanganiswe nephalethi yokhuni enezinhlangothi ezimbili ukuze kugcinwe izimpahla ezinemigqomo. Ishalofu le-beam linomthwalo omkhulu, ophephile futhi othembekile.

Qondanisa negridi eboshiwe: engeza igridi eboshiwe ensikeni ukuze wenze i-pallet yokhuni ebekiwe iphephe.

Ukumatanisa ne-Wang Zi grid block: uma ukucaciswa nosayizi wephalethi ebekwe eshalofini lensimbi kungewona umfaniswano, futhi umthwalo wephalethi awukwazi ukuhlangabezana nezinga eliphezulu lokusebenza, i-Wang Zi grid block ingangezwa.

Ukumatanisa ne-steel plate kanye ne-pallet: inqwaba yezimpahla kanye nesitoreji se-pallet yonke kuhlanganisiwe. Isitezi esiphansi sigandaywe ngepuleti lensimbi ukuze kubekwe inqwaba yezimpahla, futhi esitezi esiphezulu sifakwe i-pallet yokufinyelela i-forklift.

Enqubweni yokusebenzisa amashalofu okugcina, umphumela wamashalofu we-cross beam pallet ubonakala kakhulu. Inani layo lokusetshenziswa liboniswa ngokuyinhloko ekusebenzeni okukhethekile ngokuhambisana nobubanzi bendawo yokugcina impahla noma isakhiwo esikhethekile, njll. Lokhu kungachaza ukuthi amashalofu e-pallet e-cross beam angaba lula kakhulu ukugcinwa nokugcinwa kwezimpahla kwinqubo yokusebenza yangempela. , futhi ukuguquguquka kwayo kunamandla uma kuqhathaniswa. Ngokuvamile, inani lokusetshenziswa lamashalofu ephalethi ye-cross beam liye labonakala ngempela emabhizinisini amaningi futhi laqashelwa amakhasimende. Ukuvumelana nezimo nokuguquguquka kwayo kuye kwathuthukisa ngempumelelo izinzuzo zezomnotho zamabhizinisi ngezinga elithile, futhi amashalofu nawo asetshenziswe kabanzi ezindaweni zokugcina impahla ezisezingeni eliphezulu.

Isikhathi sokuthumela: Jul-19-2022