Eminyakeni yamuva nje, ngokuduma okuqhubekayo kwe-inthanethi, i-e-commerce ithuthuke ngokushesha. Izimpahla zoku-oda amakhasimende zibonisa izici zezinhlobonhlobo eziningi, amaqoqo ambalwa kanye nesikhathi esifushane sokulethwa, okwenza ukuminyana kwesitoreji samashalofu esikhungweni sokusabalalisa izinto zomphakeli kuqhubeke kuthuthuke. Imvamisa yezinto ezingenayo neziphumayo endaweni yokugcina izimpahla ziyanda. Inani lezingxenye ezincane ezikhethwayo liyanda usuku nosuku. Ziyanda izikhungo zokusabalalisa izinto ezisetshenziswayo zisebenzisa izimpahla ezisuselwe ezimotweni kubantu abakhethayo.

I-HEGERLS (Hebei Walker Metal Products Co., Ltd.

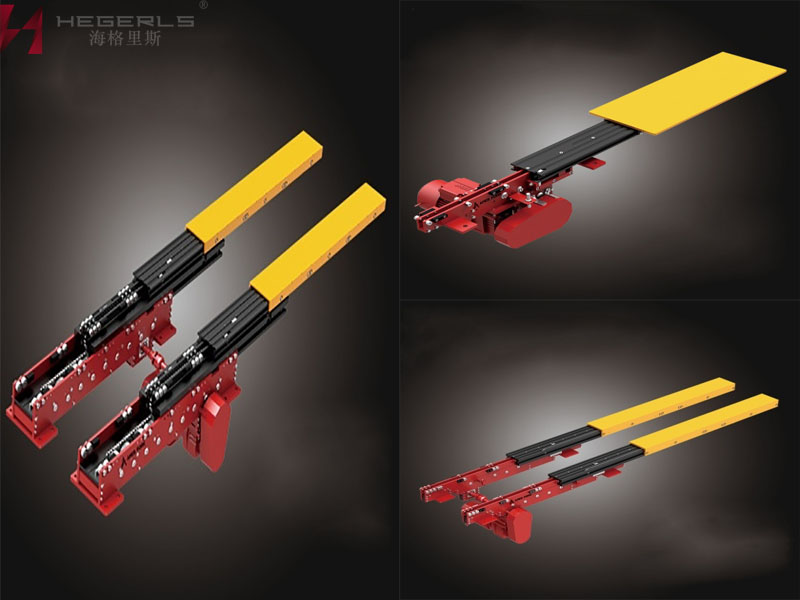

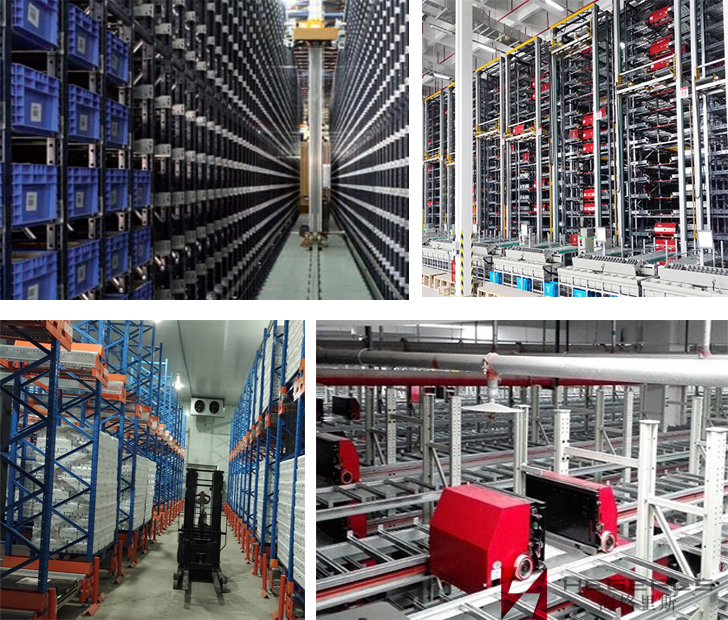

Izimfoloko ze-telescopic ezibambayo zisetshenziswa kakhulu kumishini yokugcina okuzenzakalelayo njengezimoto ze-stereo ze-shuttle multi-layer, imigqomo yohlobo lwamashalofu i-AGV, i-RGV, nomthwalo omncane. Isisindo esiphezulu sebhokisi lempahla eligcinwe yi-HEGERLS lingafinyelela ku-50Kg. Ububanzi bokubopha ingalo yemfoloko bungalungiswa ngokungenasisekelo phakathi kobubanzi obungu-200~600mm. Ubukhulu bohambo lokukhetha ngu-840mm. Isivinini esikhulu sokusebenza semfoloko ye-telescopic ngu-1.5m/s, futhi ukusheshisa ngu-1.2m/s ². Umsindo wokusebenza ulawulwa ngaphakathi kuka-75dB, ongahlangabezana nezidingo zamaracks amaningi okunwetshwa okukodwa nakabili. I-HEGERLS ingakwazi futhi ukwenza ngokwezifiso indawo yokugcina impahla ye-shuttle ye-multi-layer stereoscopic yebhokisi lemfoloko elibambayo ngokuya ngezidingo ezithile zamakhasimende, njengobubanzi bokubamba, ukucosha ukushaywa kanye namanye amapharamitha.

Izingxenye ze-Hiygris HEGERLS zibambe ibhokisi le-telescopic yemfoloko ye-multi-layer shuttle car stereo Imfoloko ye-telescopic iwumshini we-telescopic osetshenziswa endaweni yokugcina impahla ye-stereo kanye nohlelo lokuzigcina oluzenzakalelayo lokugcina impahla noma ukudlulisa. Inomsebenzi wokunwebeka wezindlela ezimbili eziguquguqukayo kanye nomsebenzi womkhawulo onembile! Ingafakwa ngokuqondile ku-stacker, noma igxunyekwe endaweni engaguquki yokuphakamisa, noma ifakwe endaweni yokuphakamisa ephathwayo. Isitaki sihamba ngomgwaqo phakathi kwamashalofu ukuze sifinyelele ngokuzenzakalelayo noma sidlulise izinto! Ingaxhunywa nesistimu yomugqa wokukhiqiza kanye nesistimu yokuphatha ibhizinisi. Isebenzisa ubuchwepheshe bekhompyutha nebhakhodi (encoder) ukuze ibone ukuphathwa nokusebenza okuhlakaniphile kolwazi!

Mayelana ne-HEGERLS Clamping Telescopic Fork

I-HEGERLS telescopic gripper fork iwuhlobo oluhlukile lwemfoloko ochungechungeni lwemfoloko ye-telescopic yezitaki, okungukuthi, imfoloko ye-othomathikhi ye-telescopic, eyaziwa nangokuthi imfoloko yokubamba noma imfoloko yokubamba, imfoloko yemfoloko noma imfoloko yemfoloko. . Kuyimfoloko esetshenziswa ngokukhethekile ukudlulisa imigqomo emincane. Ingaqoqwa ngokuqondile ku-AGV yokukha i-multi-storey noma amanye amapulatifomu asebenzayo, ngokunwetshwa kwengalo yemfoloko kanye ne-clutch ye-lever (hook), Qedela isenzo sokufinyelela noma sokudlulisa!

Imfoloko ye-HEGERLS gripper ngokuvamile yenziwe nge-aluminium alloy, enosayizi omncane, isisindo esilula, isivinini esisheshayo nokunwetshwa okushelelayo. Ngasikhathi sinye, futhi yamukela isimiso sokuvumelanisa kwezimoto eziningi, iqaphela ukuthi indlela efanayo yemfoloko ye-telescopic ingasetshenziswa ukudlulisa noma ukufinyelela amabhokisi anemininingwane ehlukene. Akugcini nje ngokuthuthukisa ukusebenza kahle kwesitoreji, kodwa futhi kuthuthukisa kakhulu izinga lokusebenzisa indawo yokugcina, ikakhulukazi endaweni yokugcina impahla enobuhlakani esezingeni eliphezulu!

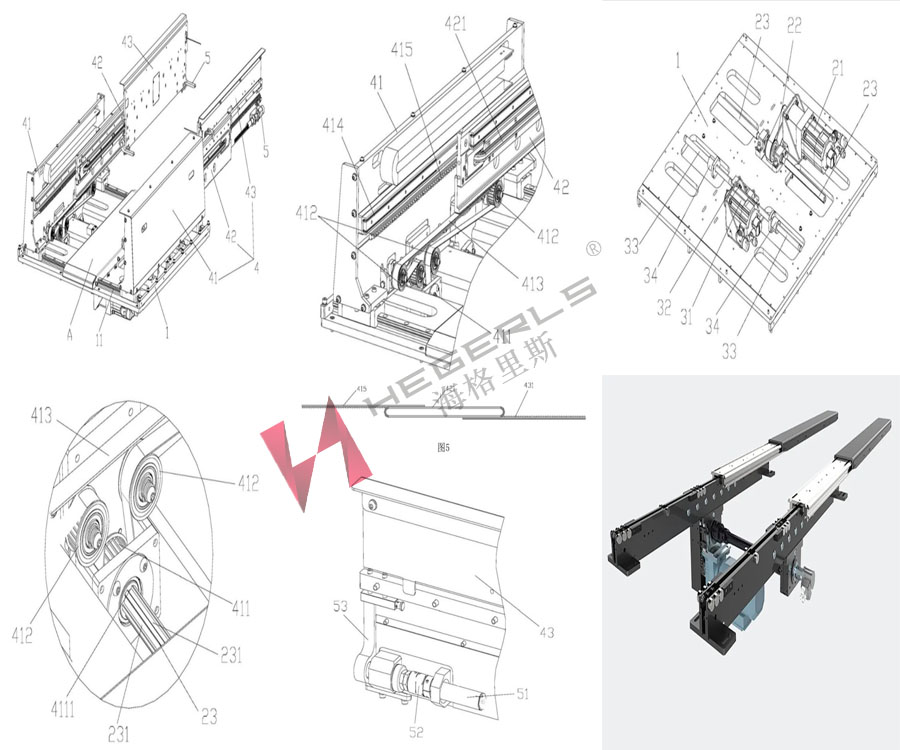

HEGERLS isiqeshana esakhiweni semfoloko ye-telescopic

Isakhiwo semfoloko ye-HEGERLS gripper singahlukaniswa sibe indawo yokugcina ejulile kanye nendawo yokugcina engajulile. Indawo yokugcina ejulile iyindawo yokugcina enamabhokisi amabili ezinto ezibonakalayo, futhi indawo yokugcina engajulile iyindawo yokugcina enebhokisi lempahla eyodwa. Okusho ukuthi, indawo yokugcina ejulile ingabopha amabhokisi ezinto ezimbili ngesikhathi, kuyilapho indawo yokugcina engajulile ingacindezela ibhokisi lempahla elilodwa ngesikhathi. Umehluko phakathi kwemfoloko yokubamba ye-HEGERLS kanye nemfoloko evamile ye-duplex telescopic ukuthi imfoloko yokudonsa umunwe isakhiwa imizimba emithathu yemfoloko, okungukuthi, umzimba wemfoloko yangaphakathi, umzimba wemfoloko ophakathi nendawo kanye nomzimba wemfoloko yangaphandle, ngaphandle kokuthi umzimba wemfoloko wangaphambili. inenduku eyodwa yokudonsa (ihuku), ehambisana nomzila wesitimela (isitimela samaslayidi), ibha yerola, isondo elivumelanayo, ibhande elivumelanayo, ibha eqephuzayo, i-shift rod (ihuku), i-jacking shaft, ibha yamasondo, i-drive motor (servo) , i-shift rod motor Ithuluzi lokubona nezinye izakhi zakha indlela ephelele ye-telescopic, esebenzisana nengalo yemfoloko ye-telescopic kanye ne-clutch ye-lever (ihhuku) ukuze kuqedelwe isenzo sokufinyelela noma sokudlulisa!

Umgomo wokusebenza wesiqeshana se-HEGERLS kwimfoloko ye-telescopic

Ingalo yemfoloko yemfoloko yokubamba ye-HEGERLS imile eseceleni futhi ixhunywe eceleni ngesitimela esiqondisayo. Ngokulawula, umzila wesitimela ungashelela emuva naphambili ukuze ulungise ibanga phakathi kwezingalo ezimbili zemfoloko zemfoloko, ukuze kuzuzwe ukusetshenziswa okuvamile kwemfoloko yamabhokisi anemininingwane eminingi! Lapho ucosha izinto zokwakha, imfoloko idlulela endaweni yokugcina impahla, ihuku lokugcina (i-lever) yehlisa ngokuzenzakalelayo futhi ivimbe ubuso bokugcina bebhokisi noma ibhokisi lepulasitiki, bese imfoloko ihoxisa, ihudulela ibhokisi noma ibhokisi lepulasitiki phakathi nendawo. imfoloko, bese iphuma ihlehla ngokuya ngezidingo zedigri, ihhuku (i-lever) idonselwa emuva, bese imfoloko ihlehla futhi ukuze kuqedelwe umsebenzi wokucosha noma wokudlulisa! Nakuba isimiso semfoloko yokubamba sifana naleyo yemfoloko ye-telescopic evamile, izingxenye zokudlulisela, izinduku zokuxhuma nezinye izingxenye zemfoloko yomunwe zihluke kakhulu. Isetshenziselwa ukuchaza ukuthi isondo leketango, iketango, igiya, irack, njll. konke kuthathelwa indawo amasondo ahambisanayo, amabhande ahambisanayo, njll., kuyilapho ingalo eshelelayo isebenzisa ama-guide rails, nezinto zomzimba zemfoloko zonke zithathelwa indawo ngamashidi ensimbi. noma izinto ze-aluminium alloy, ngakho-ke isisindo semfoloko ye-gripper singama-80kg kuphela.

Ngaphezu kwalokho, kufanele kuqashelwe ukuthi ngesikhathi sokuklanywa kwemfoloko ye-telescopic yohlobo lwe-gripper, ubukhulu bamashalofu okugcina aminyene, ukuma okuqondile kwamashalofu anamabhokisi, izinga lethrekhi nobukhulu bamabhokisi kufanele kuhlanganiswe ukuze kunqunywe imingcele jikelele yezimfoloko zokunweba (ukunyakaza kwemfoloko yokunweba, ukuhlukaniswa kwebhokisi, ububanzi bemfoloko, ububanzi bangaphakathi bemfoloko, ukuphakama kwemfoloko, njll.), ukuze kuhlangatshezwane nezidingo zeziqukathi emashalofini. Imfoloko yokugoqa ingadlulisa noma ifinyelele kuphela imikhiqizo epakishwe emakhathoni noma emabhokisini epulasitiki ngempumelelo, futhi ayikwazi ukudlulisa izinto ezingajwayelekile. Ngaphezu kwalokho, umthamo nesisindo sebhokisi lempahla edlulisiwe akufanele libe likhulu kakhulu, futhi isisindo somthwalo akufanele sidlule i-100KG! Ukuphakama kwemfoloko yokugoqa ngokuvamile kuklanywa ngokuya ngobude bomgqomo!

Mayelana ne-HEGERLS Clip ku-Shuttle

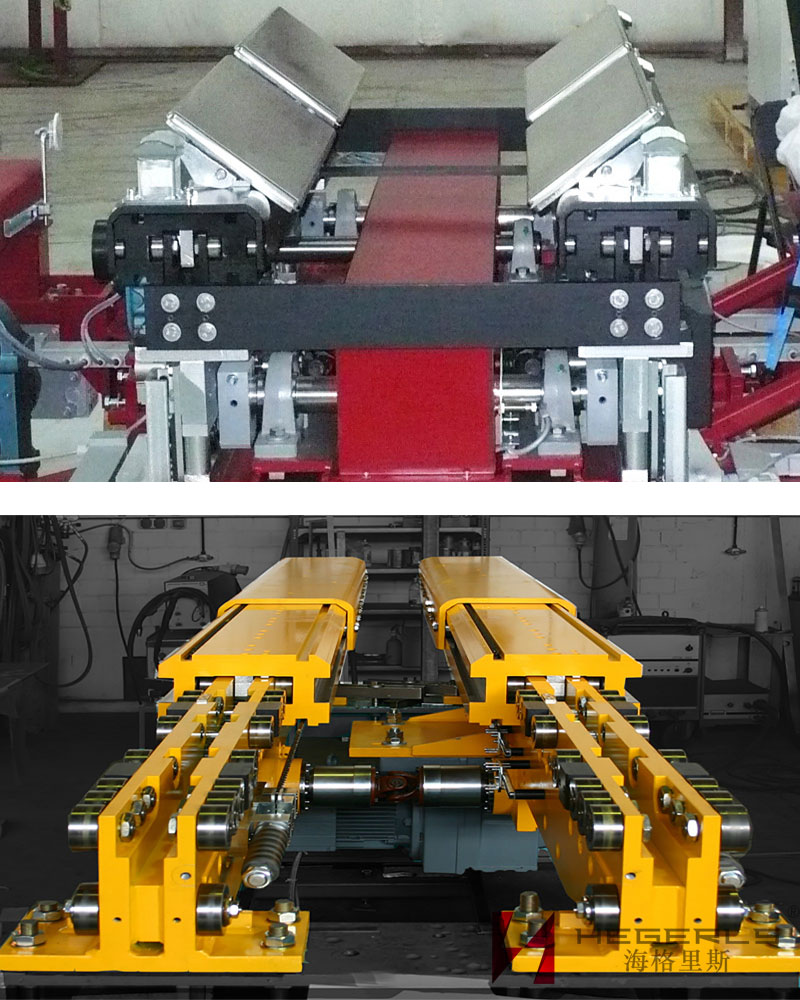

Isakhiwo sesiqeshana se-HEGERLS ku-shuttle siqukethe uzimele we-shuttle, i-shuttle chassis, indlela yokuhamba, indlela yesibili yokunwetshwa kwemfoloko, umqoqi, i-bearing plate kanye neplathifomu yokuthwala. Isakhiwo simi kanje:

Noma iyiphi i-shuttle frame ivamise ukuba imbobo evaliwe eyakhiwe abakaki bomzimba abakhulu nhlangothi zombili, igobolondo nobakaki wehabhu elingaphakathi, futhi ihlelwa ngokulandelana kuzo zombili iziphetho ze-shuttle chassis; Igobolondo lihlinzekwa ngesembozo esingaphezulu esingavulwa futhi sivalwe ngehinge lomnyango we-turnover; I-wire rack yephaneli ihlelwe ngaphezu kukabakaki wehabhu; Indlela yokuhamba ihlanganisa isondo lokushayela, isondo lokwenziwa, i-DC brushless motor, i-reducer kanye ne-shaft yokuxhuma; Zombili izinhlangothi zohlaka lwe-shuttle ekupheleni kwe-shuttle chassis zihlinzekwa ngamasondo okushayela axhunywe ngokuxhuma ama-shafts, futhi izinhlangothi zombili ze-shuttle frame ngakolunye umkhawulo we-shuttle chassis zihlinzekwa ngamasondo angenalutho axhunywe ngokuxhuma ama-shafts; I-DC brushless motor ibambisana ne-reducer ukuze ishayele isondo lokushayela futhi ishayele isondo le-passive; I-shaft yokuxhuma inikezwa nge-encoder magnetic, lapho kutholakala khona izikhundla zokuqala nokumisa i-shuttle kumzila oqondile; Indlela yesibili yokwandisa imfoloko ihlelwe ngokulinganayo ohlangothini lwangaphakathi lwefreyimu yemoto ye-shuttle; I-shuttle chassis phakathi kwezindlela zokunwetshwa kwemfoloko yesibili inikezwe isiteji sokubeka ubhasikidi wezimpahla; I-cavity evaliwe yohlaka lwemoto ye-shuttle inikezwa ngokulandelana ipuleti elithwalayo, lapho ipuleti lokushayela, ipuleti eliyinhloko lokulawula indlela yokuhamba kanye nepuleti eliyinhloko lomshini wokwandisa imfoloko kuhlelwa ngokulandelana; Ipuleti lokushayela lishayela indlela yokuhamba ukushayela i-shuttle ukuze igijime kumzila oqondile. Ibhodi lokulawula eliyinhloko lendlela yokuhamba lilawula imingcele egijimayo futhi liqale izindawo zokuma ze-shuttle, futhi ibhodi eliyinhloko lokulawula indlela yokwandisa imfoloko ilawula indlela yesibili yokwelulwa kwemfoloko ukuze ibambe futhi ibeke ubhasikidi eshalofini; Idivayisi yokuqoqa isethwe phakathi kwemoto ye-shuttle kanye nethrekhi eqondile, exhunywe nentambo kagesi ehlelwe ngaphakathi kwethrekhi eqondile futhi isetshenziselwa ukunikeza amandla emoto yokuthutha. Isici sesakhiwo sesiqeshana esisemotweni ehlakaniphile ukuze igcinwe futhi siwukuthi ama-grooves abekwe ezindaweni lapho isondo lokushayela kanye nesondo elihambayo ngokulandelana kuthinta shaft yokuxhuma, bese kumiswa indandatho e-elastic retainer emseleni ukuze yakhe i-axial. ukuma kwesondo lokushayela kanye nesondo lokwenziwa. Amasondo okuqondisa kabili abekwe ngokulandelana eceleni kwe-shuttle chassis ngaphansi kwesondo lokushayela kanye nesondo elingenalutho, naphakathi kwethrekhi eqondile kanye ne-shuttle chassis. Amasondo ahamba kabili enza umkhawulo wesokunxele nesokudla uma isondo lokushayela kanye ne-passive wheel egijima kumzila oqondile. Indlela yesibili yokunweba imfoloko ihlanganisa: ipuleti lepuleti lokunweba lemfoloko yezinga lokuqala, ipuleti leforki lesandiso lezinga lesibili, izinga lesibili le-synchronous pulley mechanism, izinga lesibili lefork extension drive mechanism, i-fork extension drive motor, esinye isinciphisi, kanye ne-drive shaft. ; Uhlangothi lwangaphandle lwabakaki behabhu lohlaka lwemoto eshuthwayo luhlinzekwa ngepuleti lokuphusha lefork yesiteji sokuqala; I-chute emise okwe-U ihlelwe phakathi nepuleti yokuphusha imfoloko yesiteji sokuqala, futhi ama-chute amaningana amise okwe-U ahlelwa ngezikhathi ezilinganayo eshutheni elimise okwe-U; Ipuleti lemfoloko lesibili lihlelwa ngaphandle kwe-chute emise okwe-U; Ipuleti yesibili yemfoloko ixhunywe namapulley amaningana e-U-shaped groove ngokusebenzisa ama-bolts namantongomane; Iziphetho eziphezulu zesiteji sesibili sefork extension plate zinikezwa ngokulandelana ngemfoloko ye-shift, i-DC planetary reducer motor kanye nenzwa ye-photoelectric kusuka ngaphandle kuya ngaphakathi; Inzwa ye-photoelectric isetshenziselwa ukuthola isignali yesikhundla semfoloko bese uyithumela ebhodini eliyinhloko lokulawula i-fork extension mechanism, elawula i-DC planetary reducer motor ukushayela imfoloko ukuhamba ngokuvundlile noma mpo; Indlela yesibili yokuphusha ehambisanayo ihlelwa ngokulandelana epuleti eliphushayo lemfoloko futhi ngqo ngaphansi nangaphezulu kwe-chute emise okuka-U; I-secondary synchronous pulley mechanism ixhunywe nepuleti yokucindezela ibhande le-synchronous ku-plate yesibili yokwandisa imfoloko; I-fork extension drive motor kanye nenye i-reducer ishayela indlela yesibili ye-fork extension drive ukuze ihambe, futhi ishayela indlela yesibili ye-fork extension drive indlela ngakolunye uhlangothi ukuze idlule ku-drive shaft, ukuze ipuleti le-primary extension extension push lihambe futhi lishayele okwesibili. Indlela yokuhambisa i-synchronous pulley ukuze ihambe, ngaleyo ndlela iqhube ipuleti lokunweba lemfoloko yesibili ukuthi lihambe. Indlela yokudlulisa imfoloko enezigaba ezimbili ihlanganisa isishumeki kazibuthe, i-synchronous belt pulley I, ibhande le-synchronous I, idivayisi yesondo elicindezelayo kanye nerack; I-pulley yebhande lesikhathi 1 kanye nebhande lesikhathi 1 zihlelwe ngaphansi kwepuleti lokuphusha imfoloko yesiteji sokuqala; Olunye uhlangothi lwe-synchronous belt pulley I luxhunywe ne-transmission shaft, kanti olunye uhlangothi luxhunywe ne-shaft yokuphuma kwesinye isinciphisi ngokusebenzisa ukhiye. Imishini yamasondo e-tensioner ihlelwa ngokulandelana kuzo zombili izinhlangothi zesinye isinciphisi ukuze kulungiswe insiza ye-synchronous belt pulley I kanye ne-synchronous belt I; I-rack ihlelwa phakathi kwepuleti yokuphusha imfoloko yesiteji sokuqala kanye nebhande le-synchronous; I-fork extension drive motor kanye nenye i-reducer ishayela i-synchronous belt pulley I kanye ne-synchronous belt I ukuze ijikeleze, futhi ishayele i-synchronous belt pulley II kanye ne-synchronous belt II ngakolunye uhlangothi ukuze ijikeleze ku-shaft yokudlulisela. Ngesikhathi esifanayo, ama-racks nhlangothi zombili ashayela ipuleti le-push ye-fork elihambisanayo elihambisanayo ukuze kuzuzwe ukunwetshwa kwemfoloko eyinhloko. Lapho umshini wepulley webhande lesibili elivumelanayo lihamba ngokuhambisanayo futhi lishayela ipuleti lesibili lemfoloko ukuthi lihambe, ipulley emise okuka-U iyagingqika kushuthi emise okuka-U, Yenza ipuleti lokunweba lemfoloko yesibili libone isandiso semfoloko yesibili. Idivaysi yesondo elicindezelayo ihlanganisa: ibhawudi, ubakaki wokulungisa, amantongomane aphindwe kabili kanye nesondo elicindezelayo; Isondo eliqinisayo lihlelwa ngaphansi kwebhande le-synchronous I nasezinhlangothini zombili zesinye isinciphisi, futhi liqiniswe kubakaki bomzimba oyinhloko ngenadi eliphindwe kabili; Ubakaki wokulungisa uhlelwa ngaphansi kwenati eliphindwe kabili ngebhawodi, futhi indawo yokubakaki yokulungisa ilungiswa yibhawudi, ukuze ubakaki olungisayo ushayele inati eliphindwe kabili ukuthi liye phezulu naphansi, ukuze ibhande lokuvumelanisa ngikwazi ukugcina isimo sokucindezeleka ngaphansi kwesenzo sesondo elicindezelayo.

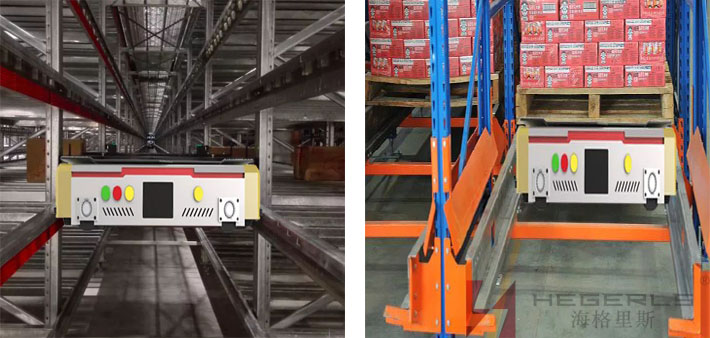

Ngabe i-HEGERLS izoshayela kanjani izinzuzo zebhizinisi?

Okokuqala, indlela yokuhamba, indlela yokwandisa imfoloko kanye nohlaka, ulayini wokuxhumana oshelelayo kanye nedivayisi yokuqoqa amandla yemoto ye-shuttle ehlakaniphile ye-HEGERLS ene-clip kwisitoreji ihlelwe ngokufanele, esisebenzisa ngokugcwele isikhala semoto yokuthutha, futhi ingakwazi ukuzivumelanisa ne- ukugcinwa okuzenzakalelayo kanye nokubuyiswa kwezimpahla zokucaciswa okuhlukene kanye nezindawo endaweni yokugcina izinto enezinhlangothi ezintathu, ukwandisa ukumbozwa kwesicelo semoto yokuthutha, futhi ngokushesha nangempumelelo uqedele uchungechunge lwezenzo eziqhubekayo zemoto yokuthutha, njengokuhamba, ukunwetshwa kwemfoloko, ukucosha. iphakamisa futhi ibeke izimpahla, Ibona ukugcinwa okusheshayo nokunembile kwezimpahla, ngaleyo ndlela ithuthukise kakhulu ukusebenza kahle kanye nezinga lobuchwepheshe bokuzenzakalela kwe-warehouse ezenzakalelayo, futhi yehlise nezindleko zokutshala izimali zamabhizinisi. Ngesikhathi esifanayo, ilula futhi ilula ngesakhiwo, ithembekile kakhulu, futhi kulula ukuyigcina. Ingathatha indawo yesitaki somgwaqo esivamile, ibona ukuguquguquka kwesistimu, futhi ihambisane nethrendi yentuthuko ye-e-commerce logistics kanye ne-warehousing automation.

Okwesibili, endleleni yokuhamba ye-HEGERLS imoto ye-shuttle ehlakaniphile, ama-shafts axhumayo amasondo okushayela kanye namasondo angenayo ahlinzekwa ngama-grooves, futhi izingxenye zokuxhuma zama-bearings zixhunywe uhlobo olusha lwe-elastic retainer ring, eqaphela umphumela we-axial positioning wokuxhuma. imishayo; Ngokusebenzisa iringi ye-elastic retainer ukuze kuzuzwe umphumela wokuma kwe-axial, ukusebenza kahle kokukhiqiza kungakhuliswa futhi izindleko zingongiwa.

Okwesithathu: I-Higelis HEGERLS imoto ye-shuttle ehlakaniphile yokubamba isitoreji iyaqaphela ukuthi isondo lokushayela kanye nesondo elihambayo lihlala lihamba endleleni eqondile ngaphandle kokuchezuka kumzila ngokusebenzisa isakhiwo samasondo ahamba kabili. Lesi sakhiwo sokuma sizinzile futhi sithembekile.

Okwesine, isakhiwo sokunwetshwa kwemfoloko yesibili esamukelwe yi-HEGERLS ehlakaniphile ye-shuttle car singenza ibanga lokunwetshwa kwemfoloko libe kude futhi zithole obhasikidi abaningi ezindaweni ezahlukene; Ngesikhathi esifanayo, isimiso sendlela yokwandisa imfoloko yesibili silula, futhi izindleko zokuklama nokukhiqiza ziphansi; Ingxenye yokudlulisela ithatha imodi ye-single motor+reducer+transmission shaft ukwenza indlela yesibili yokunweba imfoloko ifinyelele inhloso yokwandiswa nokufinyela okuhambisanayo, okonga izindleko ezengeziwe, kunciphisa ngempumelelo indawo yokuhlela edingekayo, futhi kunciphisa isisindo semoto yokuthutha. .

Okwesihlanu, i-Higelis HEGERLS i-shuttle ehlakaniphile yemoto ithatha uhlobo olusha lwedivayisi yesondo elicindezelayo, elingagcina ngokushesha ibhande le-synchronous liqinile futhi liqaphele umsebenzi ojwayelekile wemoto yokuthutha. Ngaphezu kwalokho, le divayisi yesondo elicindezelayo ilula ukwenza, kulula ukuyifaka futhi ingalungiswa ngokushesha, okonga izindleko, konga isikhala futhi kuthuthukise ukusebenza kahle komsebenzi.

Isikhathi sokuthumela: Dec-19-2022