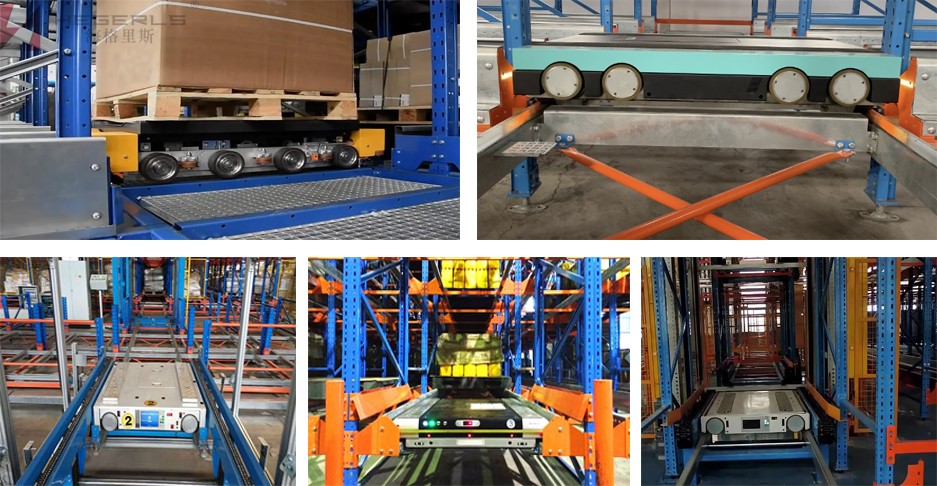

I-HEGERLS pallet four-way shuttle car stereoscopic warehouse iyisisetshenziswa sokuthutha esihlakaniphile esihlanganisa imisebenzi eminingi njengokushayela ngezindlela ezine, ukulandelela ukushintsha endaweni, ukuthutha okuzenzakalelayo, ukuqapha okuhlakaniphile, nokuphathwa kwethrafikhi ashukumisayo. Eyaziwa nangokuthi i-AGV, ingahlelwa ukuthi yenze imisebenzi efana nokucosha, ukuthutha, kanye nokubeka izimpahla endaweni yokugcina impahla, futhi ingaxhumana nohlelo lokulawula i-warehouse (WCS), ngokuhambisana nohlelo lokuphatha i-warehouse (WMS), Ubuchwepheshe bolwazi be-RFID Logistics obufana nokubonwa kwekhodi yebha kuvumela ukuhlonza okuzenzakalelayo kwezimpahla, ukufinyelela okukodwa, ukufinyelela okuqhubekayo, izibalo ezizenzakalelayo, neminye imisebenzi. Ixhunywe kusilawuli kude esingenantambo futhi ihlanganisa ubuchwepheshe bokuhlonza obufana ne-RFID nekhodi ye-QR ukuze ubone kalula ukuhlonza okuzenzakalelayo nokufinyelela kwezimpahla emashalofini.

Ngokwezidingo zomsebenzi, i-pallet four-way shuttle iloli ibambisana ne-elevator ehambisanayo ukuze iqedele imisebenzi yokusebenza ezigabeni ezihlukene zeshalofu kanye nemizila yezimpahla ehlukene ngokusebenzisa imizila ehambayo. Ngaphansi kokulawula nokuhlelwa kwesistimu yokuqapha i-warehouse, yonke inqolobane eminyene ingafinyelela ukusebenza ngesikhathi esisodwa kwezendlalelo eziningi nezimoto. Imoto enendlela emine inemisebenzi yokusebenza yokugcina inqwaba kanye nokuhoxiswa, ukunyakaza kokudluliswa kwempahla, ukubala i-pallet, njll., ukuze kuzuzwe ukulethwa kwezinto ngokushesha kanye nokuphathwa kwempahla. Ingaphakathi layo lifakwe umsebenzi wokugwema izithiyo kanye nomsebenzi we-alamu wamaphutha, onganikeza ukuvikelwa kokuphepha kanye nempendulo efika ngesikhathi yolwazi lwamaphutha.

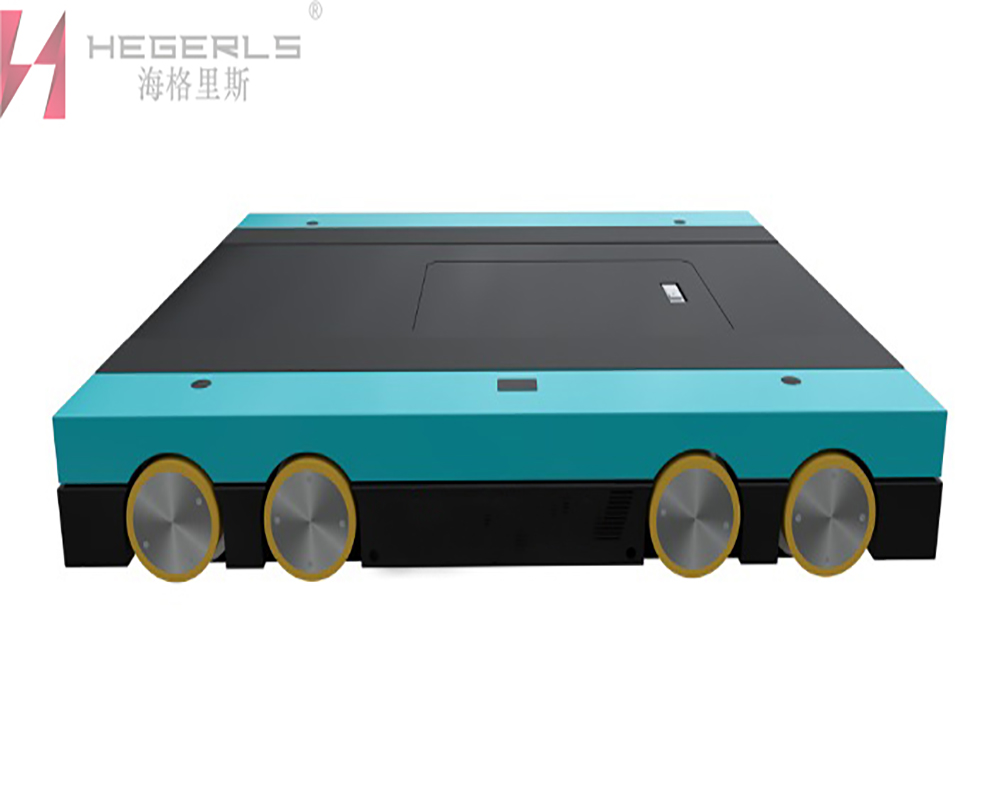

Isimiso sokusebenza se-Hercules HEGERLS pallet ye-shuttle ye-four-way carventory ukubeka i-Hercules HEGERLS pallet ye-shuttle ye-four-way ku-rack track ngaphansi kwe-pallet, ngaphansi kokuqondisa kwesistimu ye-WCS, nesiteji sokuphakamisa imoto ye-shuttle. ubheke phezulu, phakamisa iyunithi yephalethi ukuze ugijime uye endaweni oya kuyo, bese ugcina izimpahla kuphalethi endaweni yempahla.

I-HEGERLS pallet four-way shuttle ingaxazulula amaphuzu alandelayo ezinhlungu kumabhizinisi:

Iphoyinti lobuhlungu 1: Thuthukisa ukuguquguquka kwesitoreji

Idizayini eyimojuli kanye nokuqaliswa kwethreyi ye-HEGERLS yesistimu ye-shuttle car stereoscopic stereoscopic inika isuphamakethe yayo ukuguquguquka. Phakathi kwazo, i-hardware efana nezimoto ezihlakaniphile ze-shuttle ezine kanye ne-high-speed hoists inezinketho eziningi, ezingafaneleki nje kuphela izinhlobonhlobo zezakhiwo eziyinkimbinkimbi zendawo, kodwa futhi zibe nokuguquguquka okuphezulu kwendawo engakwazi ukuzivumelanisa nezimo ezihlukahlukene zezimboni, nazo. kuthuthukisa ukuguquguquka kwesigcawu. Ngaphezu kwalokho, uhlelo oluhlakaniphile lwenza ukuhlaziya ukuqaliswa kwesimo sokusebenza futhi lusabalalise ngokulinganayo imisebenzi yemisebenzi ukuze kuqinisekiswe ukuhlela okuhlakaniphile kwamadivayisi nemisebenzi eminingi.

Iphuzu Lezinhlungu 2: Ukwandisa Umthamo Wesitoreji

Uhlelo lokugcina lwe-shuttle car stereoscopic olunezinhlangothi ezine luhloselwe ikakhulukazi isimo sokusebenza kokugcinwa okuminyene kwesitoreji se-pallet stereoscopic, esingathuthukisa umthamo wokulondoloza kanye nezinga lokusebenzisa isikhala endaweni yokugcina impahla, futhi isilinganiso salo se-volumetric singafinyelela ku-40% kuya ku-60%, okuphinde kube izikhathi ezingu-4-6 isilinganiso se-volumetric yesitoreji esiyisicaba kanye nezikhathi ezingu-1.3-2 isilinganiso sevolumu yesitoreji se-stacker stereoscopic. Ngaphezu kwalokho, ukufinyelela kwe-elevator yejubane eliphezulu efakwe endaweni yokugcina impahla enezinhlangothi ezintathu zeloli ye-shuttle ye-pallet ye-four-way ingasebenzisa ngokugcwele ukuphakama kwendawo yokugcina impahla; Ukuncishiswa kwamashaneli okusebenza kanye nokusebenza okungenamuntu nemishini kwemishini ehlakaniphile nakho kunganciphisa ngempumelelo ukumoshwa kwendawo yokudlula imishini.

I-Pain Point 3: Ukuthuthukisa Ukusebenza Kwesitoreji

Isistimu yethreyi ye-Hagrid HEGERLS ye-shuttle yendlela emine ingakwazi ukuhlela ngokunengqondo okokusebenza okulindile ngokusekelwe emiyalweni, ngaleyo ndlela yehlise isikhathi sokuqalisa isisetshenziswa futhi ithuthukise ukusebenza kahle kukonke okungenayo nokuphumayo ngaphezu kuka-30% uma kuqhathaniswa nesitaki. Uma kuqhathaniswa nokusebenza kwezandla okuvamile, uhlelo lwe-pallet four-way shuttle car olunezinhlangothi ezintathu lunganciphisa futhi umsebenzi olula nophindaphindayo wezandla wokuya nokubuya ngesikhathi senqubo yokubeka impahla ngokusebenzisana okusebenzayo kwamadivayisi amaningi ahlakaniphile endaweni yokugcina izimpahla, ngaleyo ndlela kuzuzwe okungaqondiswa muntu. ukuphathwa kwebhizinisi lokugcina impahla kanye nokwenza ngcono izinga lokusebenza kwangaphakathi kwendawo yokugcina impahla. Ngesikhathi esifanayo, u-Hebei Walker uzoqhubeka nokuthuthukisa ukukhetha kwendlela nokuhlela ama-algorithms wesistimu yokusebenza yesofthiwe yemikhiqizo engaphansi komkhiqizo we-HEGERLS we-Haigris. Lokhu akugcini nje ngokukhuthaza ukwenyuka okukhulu kwezinga lokusetshenziswa kwedivayisi eyodwa, kodwa futhi kungazuza ukusebenzisana okuhlakaniphile kwesofthiwe nehadiwe kanye nomsebenzi wokuhlanganyela wamadivayisi amaningi. Uma kuqhathaniswa nomsebenzi wezandla wendabuko, ukusebenza kahle okuphelele kwendawo yokugcina impahla kuye kwathuthukiswa izikhathi ezi-2-3.

I-Pain Point 4: Ukuthuthukisa Ikhwalithi Yomkhiqizo

Amabhizinisi amaningi kufanele aqaphele ukuthi embonini yamanje, amabhizinisi amaningi azosebenzisa ukuhlolwa kwekhwalithi nokusebenza kwezingxenye zemishini phakathi nokuqaliswa nokuqedwa kwephrojekthi, kodwa umphumela ongemuva ukuthi izinhlobo ezimbozwe ngesikhathi sokuhlelwa kwendawo okusekelwe ezidingweni zephrojekthi zinomkhawulo. Ithreyi ye-Hagrid HEGERLS yethreyi ye-4-way shuttle traffic ye-3-dimensional system library izohola ekuqedeni ukuhlolwa okuphindaphindiwe kwe-multi-dimensional kwemojula ngesikhathi sokuklama nokuhlolwa kwefekthri, ukuze kuqinisekiswe ukuthi ukulungisa iphutha nokuhlolwa kwemingcele ehlukahlukene yemojula kungenziwa. ezindaweni ezihlukahlukene eziphakeme kakhulu kunalokho okungenzeka ngesikhathi sokuqaliswa kwangempela kwephrojekthi, ngaleyo ndlela kuhlinzekwe ngekhwalithi ephezulu yokulethwa kwesofthiwe namamojula wehadiwe.

I-Pain Point 5: Ukunciphisa Izindleko Zokutshalwa Kwezimali

Idizayini emisiwe nemodular yethreyi ye-Higgris HEGERLS yethreyi ye-4-way shuttle vehicle ye-three-dimensional system ingaqinisekisa ngokunembe kakhudlwana ukuthi ukwakhiwa kwe-intelligent shuttle car warehouse ene-three-dimensional kungatshalwa ngezigaba ngokusekelwe esidingweni sangempela sokugcina, nge- umthamo omkhulu ukuze kuhlangatshezwane nesidingo sangempela, ukwehlisa ngempumelelo izindleko zokuzama nezamaphutha zoshintsho oluhlakaniphile lwendawo yokugcina impahla kanye nezindleko zokutshalwa kwezimali zesigaba sakamuva sephrojekthi, kanye nokuzuza ngokushesha izinzuzo zokutshalwa kwezimali. Ukwengeza, umklamo we-modular we-hardware kuthreyi ye-HEGERLS ye-shuttle car ye-three-dimensional warehouse system ingakwazi futhi ukufeza imisebenzi engenamuntu endaweni yokugcina impahla. Le modi yokusebenza ingase futhi yehlise izindleko zokusebenza endaweni yokugcina impahla, yehle ngamaphesenti angaphezu kuka-50 uma iqhathaniswa nemisebenzi eyenziwa ngesandla.

I-Pain Point 6: Ukusheshisa Ukulethwa

Ngemuva komklamo odidiyelwe ophezulu kanye nokuqaliswa komkhiqizo we-modular we-HEGERLS, ukusebenza kahle kokuthunyelwa kohlobo lwethreyi yemoto ye-shuttle ye-three-dimensional library system izothuthukiswa kakhulu. Idizayini yesikimu sephrojekthi yendawo yokugcina impahla isebenzisa isistimu yokusebenza yendlu yokugcina impahla ehlakaniphile ye-Hebei Walker ukuze kuzuzwe idizayini ehlakaniphile, ngepulaki yemishini yemojuli nokudlala, evumela ukusebenzisana okuhlakaniphile kwamadivayisi amaningi nemisebenzi ngaphandle kokulungisa iphutha ngokuphindaphindiwe. Uguquko kanye nokuthuthukiswa kwamaphrojekthi okugcina impahla kungasatshalaliswa ngempumelelo ezinsukwini ezingama-20 kuye kwezingama-40, ngaleyo ndlela kuzuzwe ukulethwa kwekhwalithi ephezulu eyi-100% kwamaphrojekthi okugcina impahla ngaphandle kokwenzeka kwamaphrojekthi angakaqedwa.

Isikhathi sokuthumela: Mar-23-2023