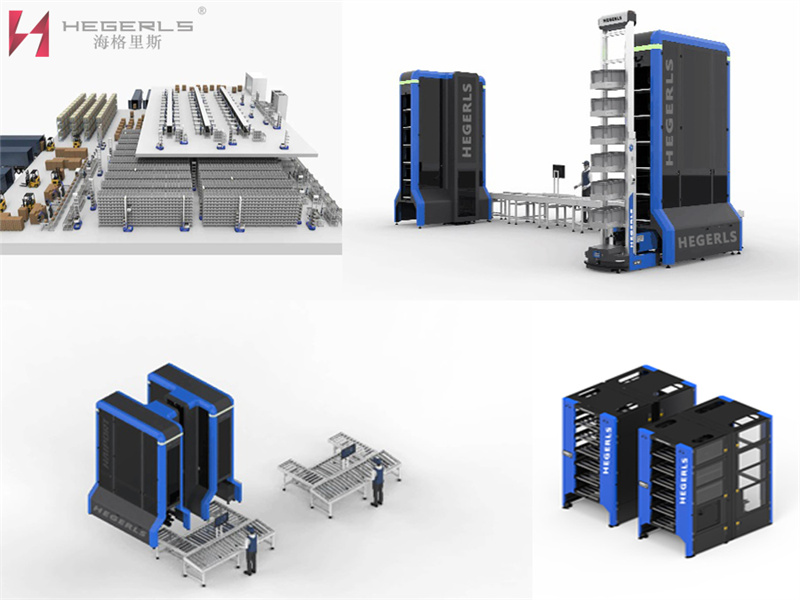

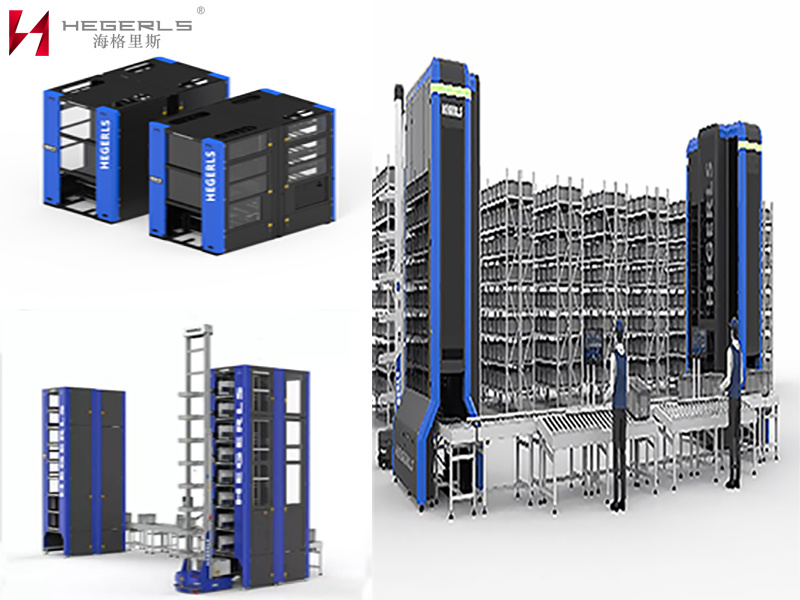

Eminyakeni yamuva nje, ngenxa yokushoda okwandayo kwezinsiza zomhlaba kanye nokwanda kwezindleko zabantu, ukuthuthukiswa okuzenzakalelayo kwemboni yokugcinwa kwempahla kanye nempahla bekulokhu kuthatha "ukunciphisa izindleko nokwenza ngcono ukusebenza kahle" njengento ehamba phambili. Eminyakeni yamuva nje, ukugcinwa kwempahla kanye nemishini ye-automation ye-logistics iye yavela ngokungapheli, kodwa abaqhubi be-warehouse bahlala benephuzu lobuhlungu: kunzima ukucabangela ukusebenza kahle kanye nezindleko. Ngenxa yaleli phuzu lobuhlungu, ithimba le-hegerls le-hegris, elinganciphisa ukuthunyelwa kwamarobhothi ngo-30%, ukunciphisa izindleko zabasebenzi ngo-66%, futhi kuthuthukiswe ukusebenza kahle kokuhlunga izikhathi ezingu-3-4, lihileleke ngokujulile emkhakheni webhokisi. isistimu yerobhothi yokugcina. Isebenza ngokukhethekile emishinini yokulayisha nokuthulula i-hegerls yerobhothi ye-kubao, ichaza imodi entsha yokusebenzisana phakathi kwezimpahla nabantu, futhi ithuthukisa ngokwengeziwe ukusebenza kahle kokugcinwa. I-Higgins hegerls indawo yokusebenza yomshini wokulayisha nokuthulula ngokuzenzakalela iphinda ichitha indlela yokusebenzisana yezimpahla kubantu, futhi ihlanganisa izici ezisebenzayo zokuphatha iziqukathi eziningi ze-bao ukuze ibone ukulayishwa nokukhishwa kweziqukathi eziningi, ithuthukisa kakhulu ukusebenza kahle kokugcinwa kwempahla nokugcinwa kwempahla.

I-hegerls i-othomathikhi yokulayisha nokukhipha umshini wokusebenzela umshini wakhiwe umshini ozenzakalelayo wokulayisha nokulayisha, ulayini wokudlulisa, i-Kanban ebonakalayo, udonga lwembewu, kanye nesistimu yokuhlunga ukukhanya. Ixhunywe namarobhothi ochungechunge lwe-kubao ukuze ethule ngokuzenzakalelayo, adlulise, futhi alayishe ibhokisi lempahla kubhasikidi ongemuva werobhothi, ukuze kubonakale umsebenzi wokulondoloza nokuthulula ozenzakalelayo. Indawo yokusebenza inomthwalo osebenza kahle kakhulu wokulayisha nokuthulula, ongaqedela ukulayishwa kweziqukathi ezingu-6 ku-3S kanye nokuthulula iziqukathi ezingu-6 ku-5S, kuthuthukisa kakhulu ukusebenza kahle kwerobhothi; Idizayini ye-modular, eguquguqukayo futhi kulula ukuyihambisa, isekela ukukhula ngokushesha / ukuncipha kwemishini, futhi ihlangabezane nezidingo zokusebenza kahle nezindleko; Abasebenzi bahlukaniswa namarobhothi ukuze kuqinisekiswe ukuphepha; Ngokuya ngedizayini ye-ergonomic, ikhonsoli yokukhetha inezinzuzo zokwenza umuntu, ukusebenza okulula, ukusebenza kahle okuphezulu kokungena nangaphandle kwesitoreji, njll. Isimo esisebenzayo: sonke isimo siyasebenza, ikakhulukazi esimweni esinenani elikhulu lezinto ezigciniwe kanye nokucosha. .v

Izimiso zokudizayina ze-hegerls ukulayisha okuzenzakalelayo nokuthulula indawo yokusebenza yomshini:

Njengomkhiqizo onesitifiketi se-ETL kanye ne-CE, umshini wokulayisha nokulayishwa kwe-haggis othomathikhi uphumelele izivivinyo eziqinile mayelana nokuphepha kwemishini, ukuphepha kukagesi, ukuphepha okusebenzayo, ukuphepha komlilo, ukuphepha komsebenzi kanye nempilo, ukuqinisekisa ukwethembeka komkhiqizo;

*Imisebenzi yokuphepha isekelwe ezimisweni zokuklama ze-ISO 12100 ezijwayelekile ukuze kuncishiswe ubungozi;

*Uhlelo lokulawula luklanywe futhi lwenziwa ngokuhambisana nezidingo ze-iec/zu 60204-1 kanye ne-ISO 13849-1, futhi amathuluzi okuphepha (iswishi ye-interlock, isitobhi esiphuthumayo) agadwa ama-relay okuphepha futhi asebenza kuphela ngaphansi kwezimo eziphephile. Izinga lokusebenza kokuphepha lifinyelela ku-PL D;

*Ukwakheka kwephaneli yokulawula kanye nebhentshi lokusebenzela lihambisana ne-ergonomics;

*I-HMI (isikhombi somshini womuntu) isixhumi esibonakalayo somshini womuntu sihlanganiswe ekhabetheni likagesi futhi sitholakala ngaphandle kwendawo eyingozi ukuvimbela noma iyiphi ingozi ebonakala;

*Wonke umnyango womshini wezinto zokusebenza ufakwe idivayisi yokuvikela i-interlock, futhi injini yokuvula umnyango ivaliwe. Umshini ungaqalisa futhi ukusebenza kuphela ngemva kokuba wonke umnyango womshini uvalekile. Ukuphepha kwabasebenzi bezokunakekela kuqinisekisiwe ngezinga elikhulu, futhi ubungozi bokuphepha buncishiswa kakhulu;

*Isistimu yokuphakamisa iklanyelwe ukumelana nephutha elilodwa futhi ivikelwe ezingozini ezihlobene namakhava avaliwe angashintshi kanye nemishini yokuvikela exhumene;

*Izisetshenziswa zokuphepha ezibalulekile zizothobelana nezimfuneko zezindinganiso zaseMelika nezaseYurophu.

Isimiso sokusebenza se-hegerls automatic loader workstation:

Iziqukathi zithathwa futhi ziphathwe yirobhothi ye-kubao, exhunywe ne-hegerls automatic loader workstation. Ukuthululwa kweziqukathi eziningi kwenziwa nge-5S, futhi iziqukathi zibuyiselwa ku-hegerls automatic loader workstation ngemva kokuhlunga. Iziqukathi zilayishwa nge-3S, ebonisa inqubo esebenzayo yokugcina impahla kanye nenqubo yokubeka impahla. Isiteshi sokusebenza somshini wokulayisha nokuthulula i-hegerls siphinde sisekele ukufakwa kwedokodo nesiguquli ukuze sibone ukuhlungwa kwezimpahla, sidale ukuzenzekelayo kwayo yonke inqubo yokungenayo nokuphumayo, futhi kuthuthukiswe ukusebenza kahle kwemisebenzi yokugcinwa kwempahla.

Izici ezisebenzayo ze-hegerls automatic loader workstation:

*Isebenza kahle futhi iyashesha - isivinini sokulayisha i-3S, isivinini sokulayisha esingu-5S

Indawo yokusebenza yomshini wokulayisha nokuthulula i-hagerls ithuthukiswe ngokukhethekile futhi yakhelwe irobhothi le-kubao. Zombili lezi zixhunywe ngobuhlakani ukuze zibone ukulayishwa nokuthululwa kweziqukathi eziningi. Irobhothi ngalinye lingaqedela ukulayishwa kweziqukathi ezingu-6-8 ngesikhathi esisodwa kumasekhondi angu-3 kuphela kanye nokukhipha ngamasekhondi angu-5. Uma kuqhathaniswa nendawo yokusebenza yolayini wokuthutha, ijubane lokulayisha nelokulayishwa kwerobhothi liphakeme izikhathi eziyi-16.

*Ukwehliswa kwezindleko kanye nokwenyuka kwekhono - thuthukisa ukusebenza kahle kwerobhothi elilodwa ngo-30%

Isixazululo esihlakaniphile sokulondoloza esisekelwe kurobhothi ye-kubao singakhuphula ukuminyana kwesitoreji ngo-80% - 130% futhi sithuthukise ukusebenza kahle kwendawo yokugcina izinto izikhathi ezingu-3-4. Ngokubambisana nesikhungo sokusebenza somshini wokulayisha nokuthulula ama-hagerls, irobhothi le-kubao lingakwazi ukulayisha nokukhipha iziqukathi ngokuzenzakalelayo, libone ukulayisha (ukukhipha) nokuhamba, futhi ukusebenza kahle kwerobhothi kunganyuka ngo-30%. Ngaphakathi kweyunithi yesikhathi esifanayo, irobhothi lingaqedela imisebenzi yoku-oda eyengeziwe, lifinyelele ukuthuthukiswa okungama-30% ekusebenzeni kahle kwesistimu, futhi indawo yokugcina impahla isebenza kahle kakhulu.

*Isimo sebhizinisi esivumelana nezimo - ukuhamba okuguquguqukayo, ushintsho olusheshayo lwendawo yokufaka, ukuqina okuqinile

Indawo yokusebenza ye-hagerls automatic loader isebenzisa idizayini eyimodulayo futhi isekela ukudokwa kohlu olugcwele lwamarobhothi e-kubao. Inguqulo eyenziwe ngokwezifiso ye-hagerls automatic loader workstation ingalayisha / yehlise iziqukathi ezingafika kweziyi-8 ngesikhathi esisodwa. I-hegerls indawo yokusebenza yomshini wokulayisha nokulayishwayo ingakwazi ukushintsha kalula indawo yayo, futhi iguqule kalula inani lezindawo zokusebenza nama-consoles ngokusekelwe ezimeni zebhizinisi, eziseduze nezimo zebhizinisi.

*Yehlisa ngempumelelo izindleko Zokuthunyelwa Okuzenzakalelayo

Ukubambisana okuphelele phakathi kwerobhothi le-Kubo kanye ne-hegerls ukulayisha okuzenzakalelayo kanye nendawo yokusebenza yomshini kunganciphisa ngempumelelo izindleko zokuphakela ze-warehousing automation. Ngaphansi kwezimo ezifanayo, ukucushwa kwe-hegerls indawo yokusebenza yomshini wokulayisha nokuthulula ngokuzenzakalela kunganciphisa inani lamarobhothi, kuthuthukise ukusebenza kahle kokugcinwa kwempahla nokuthulula, futhi kunciphise ngempumelelo izindleko zokwakhiwa kabusha kwempahla.

*Isiqukathi esiphephile esiya kumodi yomuntu

"Isitsha esiya kumuntu" esisebenza kahle esinikezwa i-hegerls indawo yokusebenza yomshini wokulayisha nokuthulula idale indlela entsha yokuthutha imithwalo phakathi kwabantu. Idizayini ye-hegerls automatic loader workstation ihambisana ne-ergonomics futhi ithuthukisa ukunethezeka kokusebenza okwenziwa ngesandla. Izimpahla zingakhethwa ngesandla endaweni ekhethiwe yesikhulumi sokusebenza ukuze kugwenywe ukuthintana ngqo nerobhothi futhi kuqinisekiswe ukuphepha kokusebenza.

*I-docking eguquguqukayo yamadivayisi ahlukahlukene

Ngezimo ezihlukene zokusetshenziswa, indawo yokusebenzela ye-hegerls automatic loader isekela ukufakwa okuguquguqukayo kwemishini ehlukahlukene: indawo yokusebenza ye-hegerls automatic loader ingacushwa ibe nezindawo zokusebenza eziningi ezenziwa ngezandla ukuze kuqedelwe ukuhlelwa kwempahla futhi kuthuthukiswe ukusebenza kahle “kwesitsha kumuntu”; Ingase futhi ixhunywe nezingalo eziwumshini nezinye izinto zokusebenza ukuze ibone ukuhlunga okuzenzakalelayo nokuthuthukisa ukusebenza kahle.

*Ukusebenzelana okunobungane kwekhompyutha yomuntu - amabhokisi angama-900 / ihora lendawo yokugcina impahla, ukuthuthukisa ukusebenza kahle kokukhetha okwenziwa ngesandla izikhathi ezi-2-3;

Ngokwezidingo ezithile zebhizinisi, i-haggis ihlinzeka ngomklamo owenziwe ngokwezifiso. Ngokusebenzisa i-hegerls ukulayisha okuzenzakalelayo kanye nokuthulula indawo yokusebenza yomshini, ukusebenza kahle kwendawo yokugcina impahla kungafinyelela ku-900 amabhokisi / ihora, okuthuthukisa kakhulu ukusebenza kahle komsebenzi futhi kuthuthukise ukusebenza kahle kokukhetha okwenziwa ngesandla izikhathi ezi-2-3.

Isikhathi sokuthumela: Jul-08-2022