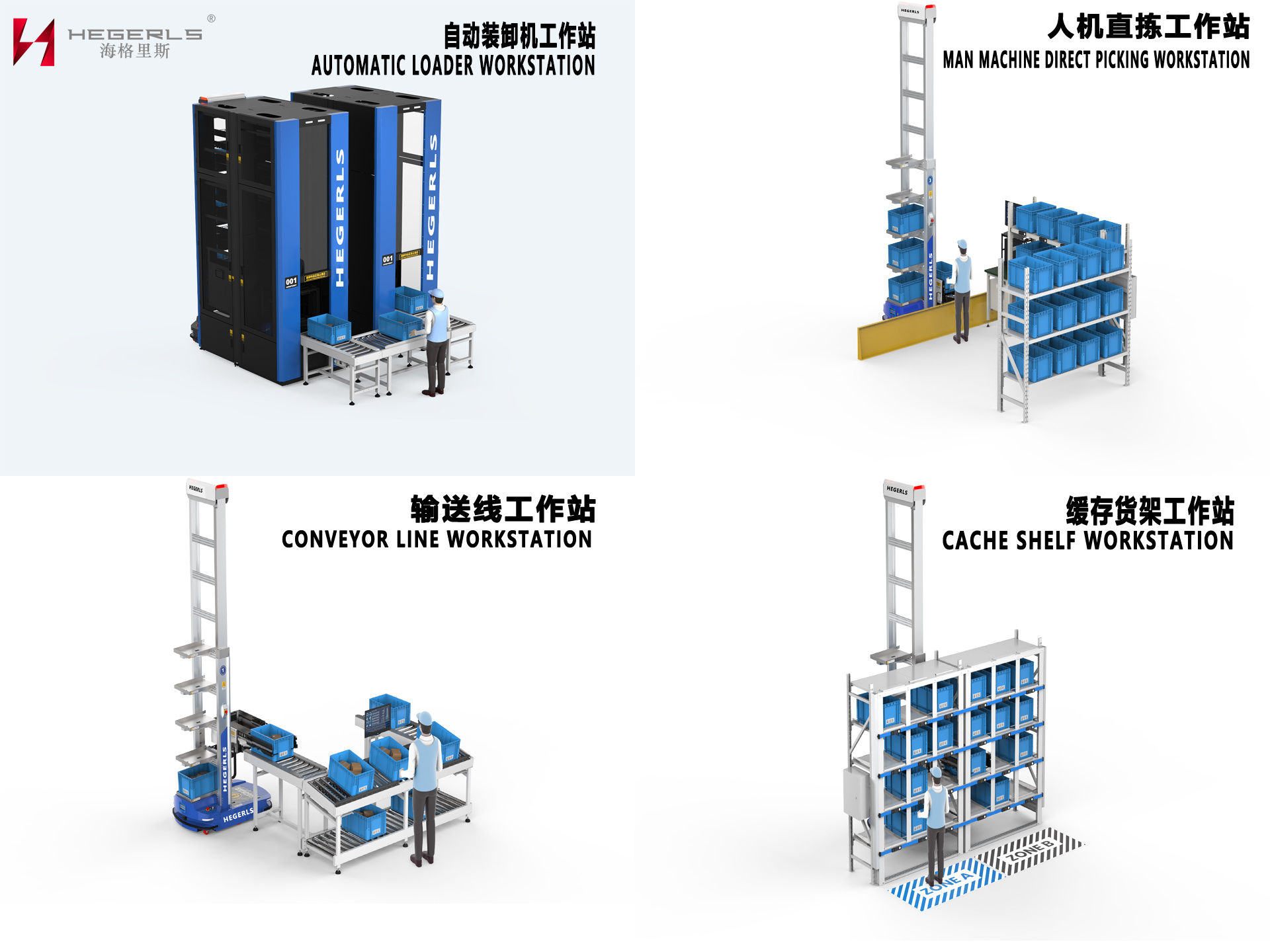

Ngokuthuthuka komkhakha we-e-commerce, imakethe idinga ukusatshalaliswa okusheshayo kanye nesivinini sokwenziwa kwezinto. Ngesikhathi esifanayo, ukukhuphuka kwamanani entengo yezemisebenzi kwenza inani lohlelo “lwempahla kubantu” libuyekezwe kabusha. Imakethe kancane kancane ithola ukuthi uhlelo "lwempahla kubantu" lungadambisa ingcindezi yokugcinwa kwempahla kanye nempahla. Kuze kube manje, kube nezinguquko ezintsha ohlelweni lokugcinwa kwezinto ezishintshayo: ukusuka endaweni okugcinwa kuyo ngesandla okuvamile ukuya endaweni yokugcina impahla esebenzisa amabhande okuthutha, izimoto zokuthutha, njll., ukuya endaweni yokugcina impahla edidiyelwe. Kulezi zinsuku, ukusetshenziswa kobuhlakani bokwenziwa kanye nama-algorithms kungene ngokusemthethweni esigabeni esisha sokugcina impahla. U-Hercules hegerls wazi kahle ukuthi ukwakha i-warehousing ezenzakalelayo kudinga ukuhlanganiswa kwemishini ehlukahlukene yezokuthutha kanye nobuchwepheshe. Muva nje, isistimu ye-kubao ethuthukiswe ama-hegerls ibonisa umsebenzi wokudokha okungenazihibe kusukela ekudluliseleni kuya ekugcinweni kuya ekuhlungeni esimeni sokugcinwa kwempahla. Ngesikhathi esifanayo, ukubambisana okuphelele phakathi kwesistimu ye-kubao nengalo yerobhothi nakho kungenza ikhono lokuhlanganisa isitoreji lesistimu ye-kubao ibonakale kakhudlwana. Ngakho-ke yini i-manipulator yesitoreji engenamuntu ezenzakalelayo? Hlobo luni lwesikhundla esiphezulu esikuso lapho kugcinwa khona izimpahla?  U-Hercules Hegels ubambe wajula ezindaweni ezibuhlungu zabasebenzisi, wabamba izidingo ezintsha zemakethe, futhi waqhubeka ethuthukisa izixazululo ezintsha ezifanele izimo ezihlukahlukene. Mayelana nokusebenzisana namakhompyutha abantu, ama-hagerls anokuqonda kwawo okuhlukile, futhi aklame izindlela nezikimu zokusebenzisana zamakhompiyutha abantu abambalwa, okuhlanganisa indawo yokusebenza ye-othomathikhi yokulayishwa, indawo yokusebenza yokuhlunga eqondile yomuntu nekhompyutha, indawo yokusebenzela yomugqa wokuthutha, indawo yokusebenzela yeshelufu yenqolobane, kanye nendawo yokusebenzela yama-manipulator. . Isigaba esiqondile simi kanje: Okokuqala, indawo yokusebenza yokukhetha eqondile ngomshini womuntu Endaweni yokusebenza yokuhlunga eqondile yomshini womuntu, opharetha angakwazi ukuhlunga ngokuqondile kubhasikidi womshini, futhi ukuhlunga kungaqedwa kuphela ngokumisa indawo yokusebenza kanye nesibhamu sokuskena. Okwesibili, indawo yokusebenza yolayini wokudlulisa Irobhothi lixhuma nolayini wokuthutha. Irobhothi libeka ibhokisi lempahla kubhasikidi kulayini wokuthutha, futhi ulayini wokuthutha uthumela ibhokisi lempahla kubantu abaphambi kwabo. Abantu bakhetha ngokuqondile ebhokisini lezinto ezibonakalayo, okuthuthukisa kakhulu ukunethezeka kokukhetha komsebenzisi futhi kugweme izinkinga zokuphepha. Okwesithathu, indawo yokusebenza yeshelufu yenqolobane Irobhothi libeka ibhokisi lempahla eshalofini lenqolobane, futhi abantu bayacosha eshalofini. Amarobhothi akhululwa futhi ahambe, akhulule ukusebenza kahle. Okwesine, indawo yokusebenza yesilayishi esizenzakalelayo Ukuze kudlalwa ngokugcwele ukusebenzisana kahle kwekhompyutha yomuntu nekhompyutha, abakwa-haggis hegerls basungula umshini wokuzilayisha nokuthulula othomathikhi, owaphinda waphazamisa indlela yezimpahla ekuxhumaneni kwabantu. Ihlanganiswe nezici zokuphatha iziqukathi eziningi ze-kubao, ibone ukulayishwa nokuthululwa kweziqukathi eziningi, futhi yathuthukisa kakhulu ukusebenza kahle kokugcinwa kwempahla nokugcinwa. Umshini ozenzakalelayo wokulayisha nokulayisha uklanyelwe ngokukhethekile uhlelo lwamarobhothi okugcina amabhokisi, uqhubekisela phambili nokusungula indlela yokusebenzisana phakathi kwezimpahla nabantu, ucebisa izinhlobo zezindawo zokusebenza ohlelweni lwezindlu zokugcina impahla, futhi uthuthukise ukusebenza kahle kwezindawo zokugcina impahla.

U-Hercules Hegels ubambe wajula ezindaweni ezibuhlungu zabasebenzisi, wabamba izidingo ezintsha zemakethe, futhi waqhubeka ethuthukisa izixazululo ezintsha ezifanele izimo ezihlukahlukene. Mayelana nokusebenzisana namakhompyutha abantu, ama-hagerls anokuqonda kwawo okuhlukile, futhi aklame izindlela nezikimu zokusebenzisana zamakhompiyutha abantu abambalwa, okuhlanganisa indawo yokusebenza ye-othomathikhi yokulayishwa, indawo yokusebenza yokuhlunga eqondile yomuntu nekhompyutha, indawo yokusebenzela yomugqa wokuthutha, indawo yokusebenzela yeshelufu yenqolobane, kanye nendawo yokusebenzela yama-manipulator. . Isigaba esiqondile simi kanje: Okokuqala, indawo yokusebenza yokukhetha eqondile ngomshini womuntu Endaweni yokusebenza yokuhlunga eqondile yomshini womuntu, opharetha angakwazi ukuhlunga ngokuqondile kubhasikidi womshini, futhi ukuhlunga kungaqedwa kuphela ngokumisa indawo yokusebenza kanye nesibhamu sokuskena. Okwesibili, indawo yokusebenza yolayini wokudlulisa Irobhothi lixhuma nolayini wokuthutha. Irobhothi libeka ibhokisi lempahla kubhasikidi kulayini wokuthutha, futhi ulayini wokuthutha uthumela ibhokisi lempahla kubantu abaphambi kwabo. Abantu bakhetha ngokuqondile ebhokisini lezinto ezibonakalayo, okuthuthukisa kakhulu ukunethezeka kokukhetha komsebenzisi futhi kugweme izinkinga zokuphepha. Okwesithathu, indawo yokusebenza yeshelufu yenqolobane Irobhothi libeka ibhokisi lempahla eshalofini lenqolobane, futhi abantu bayacosha eshalofini. Amarobhothi akhululwa futhi ahambe, akhulule ukusebenza kahle. Okwesine, indawo yokusebenza yesilayishi esizenzakalelayo Ukuze kudlalwa ngokugcwele ukusebenzisana kahle kwekhompyutha yomuntu nekhompyutha, abakwa-haggis hegerls basungula umshini wokuzilayisha nokuthulula othomathikhi, owaphinda waphazamisa indlela yezimpahla ekuxhumaneni kwabantu. Ihlanganiswe nezici zokuphatha iziqukathi eziningi ze-kubao, ibone ukulayishwa nokuthululwa kweziqukathi eziningi, futhi yathuthukisa kakhulu ukusebenza kahle kokugcinwa kwempahla nokugcinwa. Umshini ozenzakalelayo wokulayisha nokulayisha uklanyelwe ngokukhethekile uhlelo lwamarobhothi okugcina amabhokisi, uqhubekisela phambili nokusungula indlela yokusebenzisana phakathi kwezimpahla nabantu, ucebisa izinhlobo zezindawo zokusebenza ohlelweni lwezindlu zokugcina impahla, futhi uthuthukise ukusebenza kahle kwezindawo zokugcina impahla.

Esigabeni sakamuva, ama-hegerls aphinde athuthukisa i-hegerls manipulator, okungukuthi i-hegerls i-othomathikhi ngokugcwele indawo yokusebenza ye-manipulator yesitoreji, etholwa kakhulu yi-manipulator esikhundleni semanuwali, ukuxhunywa kwendawo yokusebenza yolayini wokuthutha noma indawo yokusebenza yesilayishi esizenzakalelayo. Ulayini wokudlulisa noma umshini wokulayisha nokuthulula ngokuzenzakalela uxhunywe namarobhothi ochungechunge lwe-kubao ukuze udlulise ngokuzenzakalelayo amabhokisi wezinto ezingalayishiwe noma amabhokisi wezinto ezidinga ukulayishwa. Ingalo eyimishini ingena esikhundleni sabasebenzi ukuze bahlele izimpahla ze-oda, futhi ibona inqubo ezenzakalelayo yokugcina impahla engenamuntu. Inezinzuzo zokuzenzakalela okuhlakaniphile, izindleko zezisebenzi ezingasebenzi, indawo yokugcina impahla ephumelelayo kanye nokugcinwa kwempahla. I-Kubao ibona ukugcinwa nokuphatha okuhlakaniphile endaweni yokugcina amanzi, ibamba ingalo ewumshini, ukuhlunga ngobuhlakani izimpahla ezincane ngengalo ewumshini, futhi inqubo yokulethwa nokugcinwa kwempahla iqedwa ulayini wokuthutha. Inqubo yokuhlunga yesikhulumi sokusebenza mathupha iye yashiywa, futhi yonke inqubo yokusebenza okungenamuntu isetshenziswa ezimweni ezihlukahlukene zokufaka isicelo, okuhlanganisa ukufika kwezimpahla kanye nokukhiqizwa kokukhiqiza. Isimo esisebenzayo: sisebenza ikakhulukazi esimweni sokukhetha izinto ezithengiswa esuphamakethe.

Izici ezisebenzayo zama-hagerl ngokuzenzakalela indawo yokusebenza yesikhohlisi esingenamuntu Ukukhulula abasebenzi - thola indawo yokugcina impahla ezenzakalelayo futhi engenamuntu, esikhundleni sabasebenzi ukuze bahlele izimpahla, futhi baqaphele ukugcinwa kwempahla okuzenzakalelayo kanye nokugcinwa kwempahla; Ukuhlunga okuhlakaniphile - isistimu yesikhulumi sokuphatha esihlakaniphile i-haiq ixhuma ngaphandle komthungo nesistimu yokulawula ukunyakaza kwe-manipulator, futhi ithumela ngokuqondile imiyalelo yokuqondisa umshini wokukhohlisa ukuze ahlunge izimpahla; I-docking eguquguqukayo - ukufakwa kwedokodo ngamarobhothi e-kubao, imigqa yokuthutha, amashalofu enqolobane noma imishini yokulayisha nokuthulula ngokuzenzakalelayo ukuze kuhlangatshezwane nezidingo zezimo zebhizinisi ezahlukene; Ukugcinwa kwempahla okusebenzayo nokuphumayo - irobhothi ngalinye lithwala amabhokisi angama-25-35 liphuma / ihora +25-35 amabhokisi ngehora, futhi ukugcinwa kwempahla nokusebenza kahle kwe-egress kungafinyelela kumabhokisi angama-300 ngehora.

I-Hagerls igxile ku-R & D kanye nokuklama kohlelo lwamarobhothi okugcina impahla ehlakaniphile, futhi izibophezele ekwehliseni izindleko nokwandisa ukusebenza kahle kwamakhasimende ngobuchwepheshe berobhothi kanye ne-algorithm yobuhlakani bokwenziwa, ukuze bakhe uhlelo olusebenzayo, oluhlakaniphile noluguquguqukayo lokugcina impahla. Ukuqashelwa kwemakethe namakhasimende kuzoba amandla okuqhuba inqubekelaphambili eqhubekayo ye-Hegels. U-Hagerls uzobe ebambe iqhaza ngokujulile ekusunguleni nasekuthuthukiseni i-R & D, egxile ku-R & D nasekuklanyweni kwesistimu yamarobhothi esitoreji esihlakaniphile. Ngasikhathi sinye, izothuthukisa uhla olubanzi lwezimo zohlelo lokusebenza ukuxazulula izindawo ezibuhlungu zesitoreji samakhasimende futhi ihlangabezane nezidingo zesitoreji zamakhasimende. Amarobhothi nobuchwepheshe bobuhlakani bokwenziwa bungenisa inkathi yentuthuko, ngamathuba nezinselelo ezikhona. Ngokuzayo, ama-hagerl azobambelela ekusungulweni nasekuthuthukisweni kwezobuchwepheshe, agxile ekuhlukaniseni amarobhothi okugcina amabhokisi, futhi akhulise kancane kancane umkhiqizo kanye ne-matrix yokusebenza ngokusekelwe kumaphuzu obuhlungu okugcinwa kwamakhasimende, ukuze aqhubeke nokuhola intuthuko nenqubekelaphambili yesigaba. imboni.

Isikhathi sokuthumela: Jul-08-2022