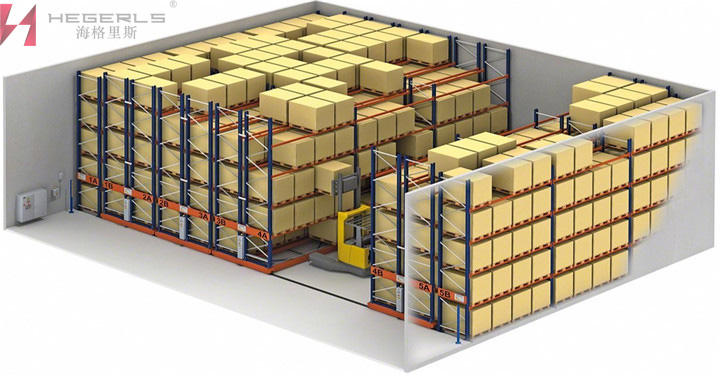

Isistimu yeshelufu ephathwayo kagesi ingenye yezinhlelo zamashalofu okugcina abantu abaningi. Uhlelo ludinga isiteshi esisodwa kuphela futhi izinga lokusebenzisa isikhala liphezulu. Ifanele izindawo zokugcina impahla ezinezindleko eziphakeme endaweni ngayinye yeyunithi, njengamashalofu okugcina abandayo, amashalofu okugcina angaqhumi, njll. I-trolley ethwala umthwalo iqhutshwa injini, futhi i-cross beam rack ibekwe ku-trolley ukuze iguqule imvamisa. ukulawulwa kwesivinini. I-rack ilinganisela ngokwedlulele kusukela ekuqaleni kuya ku-braking, futhi ukusebenza kuqinisekisiwe. Lolu hlobo lwerack lunomsebenzi wokulawula ukuguqulwa kwama-frequency, ongalawula isivinini lapho ushayela futhi ume ukuvimbela izimpahla ezikurekhi ukuthi zinganyakazi, zitsheke noma zilahlwe. Inzwa ye-photoelectric yokubeka kanye ne-gear motor motor nayo ifakwe endaweni efanele, okuthuthukisa ukusebenza kokuma.

Umthamo wokugcina weshelufu elihamba ngogesi likhulu kuneshalofu lesitoreji esingaguquki lendabuko. Umthamo wokugcina ungaba mkhulu ngokuphindwe kabili kuneshalofu lephalethi lendabuko, ukonga indawo yokugcina impahla, futhi izinga lokusebenzisa umhlabathi lingama-80%. Ifanele ukugcinwa kwezimpahla ezinamasampula amancane, amanani amaningi namafrikhwensi aphansi. Kulula ukufinyelela entweni ngayinye yezimpahla ngaphandle kokuthintwa ukuhleleka kwempahla. Ingalawulwa ngekhompyutha, ngokusebenza okulula kanye nokuphathwa kokusungula okulula.

Amaphuzu abalulekile womklamo wesikimu weshalofu leselula likagesi

1) Indawo yokusebenza okungenani engu-500mm izobekelwa eceleni eduze nodonga;

I-2) Ikholomu esakhiweni ayithinti ukuhamba kwamashalofu kuzo zombili iziphetho zekholomu, futhi ubuchwepheshe obuvuthiwe buyatholakala ukuze kuqinisekiswe ukunyakaza okuhambisanayo kwamashalofu amabili;

3) Isendlalelo se-crossbeam esingaphansi kwendawo yokubeka ephathwayo kagesi izoklanywa ngegridi noma insimbi noma ipuleti legridi;

4) Amafreyimu angashintshi azoklanywa kuzo zombili iziphetho ngokusemandleni;

Indawo yokubeka ephathwayo kagesi kanye nezidingo zepharamitha yemishini

◇ izinto eziyinhloko kanye nokucaciswa kwe-rack ehambayo kagesi

Ikholomu yenziwe ngensimbi yekhwalithi ephezulu ye-Q235, enesakhiwo sesigaba esithi "Ω" esinosayizi wesigaba esingu-90 * 67 * 2.0, futhi ugongolo lwenziwe nge-100 * 50 * 1.5 clasp beam. Ibanga eliqhubekayo lembobo yekholomu lihlelwe ngendlela eqondile nebanga elingu-50mm. Imbobo yekholomu isetshenziselwa ukulenga ugongolo kanye ne-laminate, futhi ingalungiswa phezulu naphansi ngo-50mm ukuze kube lula ukuqaqa nokuhlanganisa;

◇ incazelo yohlelo lwesakhiwo somshini we-rack ehambayo kagesi

I-1) Ucezu lwekholomu ye-rack yisakhiwo esihlanganisiwe, esakhiwe ngezinsimbi eziningana eziphambanayo, ama-diagonal braces namakholomu axhunywe futhi ahlanganiswe ngamabhawodi anamandla aphezulu. Isiqephu sekholomu ye-rack kanye nesisekelo seselula sixhunywe ngama-bolts;

2) I-crossbeam kanye nocezu lwekholomu kuxhunywe ngokuthambekela kabili ngaphambili kokuvala ipulaki-in ye-3-claw, futhi ifakwe izikhonkwane zokuphepha, ezingavimbela ngempumelelo izingozi ezifana nokufohla ugongolo ngenxa yamaphutha okusebenza kwe-forklift;

3) Imigqa emibili yamashalofu aseduze abuyela emuva axhunywe ama-spacers endaweni yokuphakama ukuze aqinise ukuzinza okuphelele kwemigqa emibili yamashalofu;

I-4) Yonke imishayo ibekwe ngama-laminates ensimbi, futhi amathreyi abekwe ahlanzekile ngemishayo. I-galvanized mesh ingafakwa ngemuva kweshalofu ukuvimbela izingozi ezingase zibangelwe i-pallet offset noma ukuwa kwezimpahla ezincane futhi kuqinisekiswe ukuphepha;

5) Amasondo enziwe ngensimbi ekhethekile yokufa, enempilo yesevisi engaphezu kweminyaka engu-5;

I-6) I-chassis yenziwe nge-4.5mm yensimbi ephezulu yepuleti, egobile futhi yakhiwe ngokukhiqiza isikhunta esivulekile esizimele. Izimbobo zokubeka ezifana ne-axle zinembile, zinamandla okuthwala aqinile nokubukeka okuhle;

7) Isendlalelo ngasinye sibekwe ngensimbi yongqimba lwensimbi, 50 * 100 * 5.0mm, imigoqo emi-2 ungqimba ngalunye, izingcezu ezi-2 / ungqimba;

8) Inombolo yamashalofu yakhelwe ukuthi ibe ngu-3000.

◇ incazelo esebenzayo yemishini yokubeka kagesi ehambayo

I-1) Indlela yokusebenza kwemishini: isistimu yokubeka iselula kagesi ilawula ukunyakaza okuya phezulu naphansi kweyunithi yokubeka ngenkinobho yokusebenza ebhalwe ngesandla kuphaneli yebhokisi lokulawula leyunithi yokulawula engaphansi. Ukunyakaza kumodi yokulawula i-inches, okungukuthi, ngemuva kokucindezela inkinobho ehambisanayo yesiteshi ezovulwa, ukunyakaza kuzoqala nge-buzzer prompt futhi kume ngokuzenzakalelayo ngemuva kokuthi isisendaweni. (uyakhunjuzwa i-haigris: isikhala seshalofu kufanele sigcinwe cishe ngo-110mm)

2) Umsebenzi wenkomba yezisetshenziswa: iyunithi ngayinye yeshalofu kagesi yeselula inikeza ulwazi oluhlukahlukene lwezinkomba ezifana nesixwayiso sokusebenza kwe-buzzer, inkomba yokusebenza kanye ne-alamu yephutha.

3) Imishini yokumisa izimo eziphuthumayo kanye nomsebenzi we-alamu yephutha: ibhokisi lokulawula iyunithi yensimu linomsebenzi wokumisa okuphuthumayo. Lapho inkinobho yokumisa izimo eziphuthumayo yebhokisi lokulawula iyunithi icindezelwa, iyunithi yokuhambisa iyayeka ukusebenza; Ngemuva kokuthi isimo esiphuthumayo sesikhululiwe, isistimu ingasebenza ngokujwayelekile kuphela ngemuva kokuqinisekiswa kwephutha.

◇ ukwakheka kanye nokucushwa kagesi ezihambayo yokubeka uhlelo

I-1) Imishini yokulawula ye-elekthronikhi yongqimba lokulawula imishini yakhiwe ibhokisi lokulawula iyunithi, ulayini wokusabalalisa amandla kanye nedivaysi yokuthola ukusebenza. Ibhokisi lokulawula kude leyunithi yensimu: ngokuya ngesakhiwo se-rack yeselula kagesi esizeni, i-rack ingahlukaniswa ngamayunithi ama-3. Iyunithi ngayinye ye-rack yeselula ifakwe ibhokisi lokulawula. Isiguquli sefrikhwensi yedrayivu kanye nesekethe yokulawula kulungiselelwa ebhokisini ukuze kuqedelwe imisebenzi ye-inchi yokunyakaza okuqhubekayo nokugcina isikhala esimisiwe sama-rack.

2) Ishalofu leyunithi lilawulwa isiguquli semvamisa ukwenza ukunyakaza kweshalofu kushelele futhi kube nomthelela mahhala futhi kugweme ukuzamazama ngesikhathi sokusebenza. Ukunyakaza nokubeka imisebenzi kuqedwa ngokuqoqa amasignali esici sokuthola (njengamaswishi e-photoelectric) endaweni yokusebenza nokulawula ama-activator enqubo (njengama-contactor, amalambu ezinkomba, njll.).

◇ amandla e-rack ehambayo kagesi nokulawula imingcele ye-voltage

Ukusatshalaliswa kwamandla kwesendlalelo sokulawula semishini yeshelufu yeselula kagesi kusebenzisa imodi yokuphakelwa kwamandla enamazinga amabili, okungukuthi, ukusatshalaliswa kwamandla aphansi we-workshop kuya kudivayisi yokusabalalisa amandla yesistimu yokulawula kagesi, ukusatshalaliswa kwamandla kusuka ekusabalaliseni amandla. idivayisi eya ebhokisini lokulawula insimu yeyunithi, kanye nokunikezwa kwamandla kusuka ebhokisini lokulawula insimu kuya enjini yemishini. Izinga ngalinye lokudluliswa kwamandla lisebenzisa iswishi yokuvikela ukuvikela izinga elilandelayo lemishini.

◇ Izidingo zokuphakelwa kwamandla kagesi wokubekelwa phansi

1) Ukunikezwa kwamandla: 400VAC ± 10%, 50Hz ± 1Hz, isistimu yezintambo ezinhlanu zezigaba ezintathu; I-AC380 / 400V (50 / 60Hz) 0.4KW, ezimbili / isitimela, isistimu yocingo yezigaba ezintathu;

2) Ukunikezwa kwamandla asizayo: 220VAC ± 10%, 50Hz ± 1Hz, uhlelo olulodwa lwezintambo ezimbili;

3) Izinga le-Voltage lenkinobho nesibani senkomba: 24VDC;

4) Izinga le-voltage yedivayisi yokutholwa yi-24VDC;

◇ umzila wesitimela ohambayo kagesi ushumekiwe

Indawo yokubeka ephathwayo kagesi idinga ukushumekwa namareyili angumhlahlandlela, enzelwe ngokukhethekile i-Party B, ngakho-ke ukufakwa kudinga ukwenziwa ngokuya ngesizinda sezimo zobunjiniyela bomphakathi.

Ikhotheshini yeshelufu kagesi ye-Hegerls: ngaphambi kwekhotheshini kanye nekhotheshini, inkampani yethu idinga ukwazi idatha yangempela yangempela yezindawo zokugcina izimpahla zamabhizinisi amakhulu ngaphambi kwekhotheshini kanye nekhotheshini. Ngokwesibonelo:

1) Imidwebo yesakhiwo se-CAD yendawo yokugcina impahla, noma idatha yobukhulu yendawo yokugcina impahla elinganiswa esizeni.

2) Usayizi wephalethi, isiqondiso semfoloko, ububanzi bephalethi, ukujula nokuphakama kwedatha.

3) Layisha idatha yephalethi ngayinye.

4) Idatha etholakalayo yobude be-net of the awarehouse.

5) Amamodeli awo wonke ama-forklift, noma iziteshi zokusebenza ezidingwa ama-forklift, anokuphakama okukhulu kokuphakamisa.

6) Inqubo yempahla yangaphakathi yendawo yokugcina impahla.

Isikhathi sokuthumela: Aug-19-2022