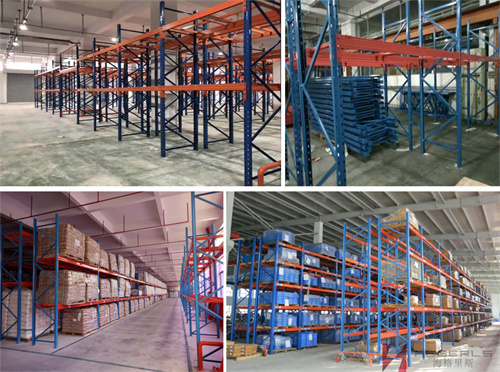

Ishalofu idlala indima ebalulekile Logistics yesimanje. Ukumiswa kanye nokwenza kube yisimanjemanje ukuphathwa kwempahla kuhlobene ngqo nezinhlobo nemisebenzi yamashalofu. Amashalofu angenza ngokuphelele indawo yokugcina impahla ibe yigugu, axazulule imfuhlumfuhlu yendlu yokugcina impahla, futhi axazulule inkinga yerenti ebizayo ngenxa yendawo yokugcina impahla enganele. Ishalofu le-cross beam liwuhlobo lweshalofu elisetshenziswa kabanzi ezindaweni zokugcina izimpahla ezimbonini ezahlukahlukene. Inomthamo omkhulu wokuthwala futhi ingasebenzisa ngokugcwele indawo. Ifakwe ama-forklift ahlukahlukene noma izitaki, ingakwazi ukubona ukufinyelela okusheshayo kuma-pallets noma amayunithi okugcina.

Mayelana nama-hagerls warehousing

Eminyakeni yamuva, inkampani yethu (i-hagerls warehousing) yenze amaphrojekthi amaningi ahlobene namashalofu e-cross beam ezimbonini nasemabhizinisini ahlukene. I-Hagerls iphinde ibe ngumkhiqizi weshalofu lokugcina ovele e-Hebei eminyakeni yamuva ye-20, egxile ekuhleleni, ekuklanyeni, ekukhiqizeni, ekuthengisweni, ekufakweni nasensizakalweni. Ikomkhulu e-Shijiazhuang, isizinda sokukhiqiza i-Xingtai, i-Bangkok, Thailand, Kunshan, Jiangsu kanye namagatsha okuthengisa e-Shenyang. Inesizinda sokukhiqiza kanye ne-R & D esingamamitha-skwele angu-60000, imigqa yokukhiqiza ethuthukisiwe yomhlaba engu-48, kanye nabantu abangaphezu kuka-300 ku-R & D, ukukhiqiza, ukuthengisa, ukufakwa kanye nokuthengisa ngemva kokuthengisa, kuhlanganise nabantu abacishe babe ngama-60 abanochwepheshe abakhulu kanye nonjiniyela omkhulu. izihloko. Amashalofu okugcina kanye nemishini yokugcina impahla ekhiqizwe yinkampani kuqinisekiswe yi-SGS, BV kanye ne-TUV izikhungo zokuhlola izinga lomkhiqizo wamazwe ngamazwe, “ikhwalithi, imvelo kanye nempilo” isitifiketi se-ISO ezintathu zesistimu, njll ngesikhathi esifanayo, bawine iziqu kanye ukuhlonishwa "kwekhwalithi yesevisi yekhwalithi yaseShayina yebhizinisi lomkhiqizo we-AAAA", "ibhizinisi elijwayelekile lokuqinisekisa ikhwalithi yomkhiqizo", "umkhiqizo womkhiqizo odumile waseChina" nokunye.

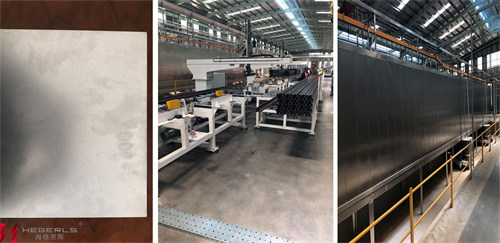

Inkampani inenani lemishini yokukhiqiza enembayo, imigqa yokufafaza efanelekile kanye nezinhlelo zokufutha ngaphambi kokwelashwa, imigqa eminingi yokukhiqiza egoqayo eyakhiwe ngendlela ebandayo kanye nemigqa yokukhiqiza egoqayo enemisebenzi eminingi ekhiqizwe ubuchwepheshe obuvuthiwe, imigqa yokukhiqiza eqhubekayo yokubhoboza ezenzakalelayo yamapheshana ensimbi. kanye nenani lemigqa yokukhiqiza ukushisela okuzenzakalelayo kwe-CO2; Imishini ephelele kanye nobuchwepheshe obuvuthiwe bungakwazi ukuxazulula izinkinga ezihlobene nokugcinwa kwempahla kanye nempahla yamabhizinisi ezimbonini ezahlukene. Mayelana nokuphathwa kwekhwalithi, silandela ngokuqinile izinhlelo ezintathu ze-ISO “zekhwalithi, imvelo kanye nempilo”, sihlala sithatha ubuchwepheshe bokuphatha obuvuthiwe bamabhizinisi asekhaya nakwamanye amazwe okugcina impahla kanye nokukhiqiza, futhi sihlala sithuthukisa ubuchwepheshe obusha futhi sethula imikhiqizo emisha ngokuhambisana ne isimo sangempela samabhizinisi asekhaya. Ngokwezidingo zamakhasimende ahlukene, inkampani yethu ingakwazi futhi ukwenza ngokwezifiso amashalofu ahlukahlukene alula, aphakathi nendawo nasindayo kanye nemishini ehlukahlukene yokugcina impahla. Njengamanje, amashalofu amaningi okugcina kanye nemishini yokugcina isetshenziswe ku-logistics, izindiza, i-electronics, izimoto, ezokwelapha, ezempi, amandla nezinye izimboni.

Inkampani yethu inaka ukuxhumana phakathi kwemikhiqizo nemakethe, kanye nethimba lomkhiqizo we-R & D elinolwazi olukhethekile, ngenkathi libamba ikhwalithi yomkhiqizo, liyaqhubeka nokuthuthukisa amamodeli amasha afanele ukufunwa kwemakethe. Ukuthuthukiswa kokucaciswa okuphezulu nokuhlukahluka kwenza imikhiqizo yethu ihlanganise kangcono izidingo ezihlukahlukene zezindawo zokugcina izimpahla zesimanje, kuthuthukisa kakhulu ukusebenza kahle kokugcinwa kwezindawo zokugcina izimpahla, nokufeza inhloso yokusetshenziswa kakhulu kwenani lesitoreji.

I-heavy beam rack (i-racking ekhethiwe)

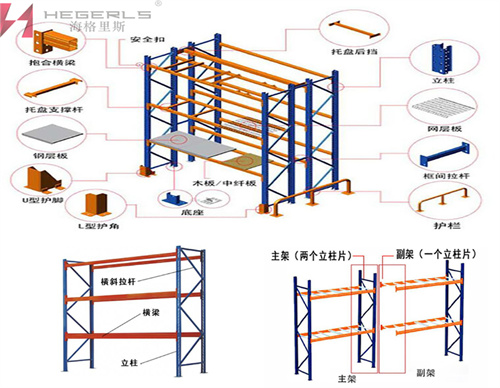

Ishalofu lohlobo lwe-Beam liyishelufu lesitolo ngenjongo yokugcina nokugcina impahla ye-pallet. Iphalethi ngalinye liyindawo yokugcina, ngakho libizwa nangokuthi ishalofu lohlobo lwesikhala sokugcina. I-heavy-duty crossbeam rack ilula ngesakhiwo, iphephile futhi inokwethenjelwa, futhi ingalungiswa futhi ihlanganiswe ngokuthanda kwayo, futhi ayinqunyelwe ukulandelana kwezinto ezingaphakathi nangaphandle kwendawo yokugcina impahla. Ucezu lwekholomu lweshalofu le-cross beam luxhunywe yikholomu, i-cross brace kanye ne-diagonal brace ngamabhawudi. Ucezu lwekholomu kanye ne-welding beam emise okwe-C ifakwe ukwenza ifreyimu yeshalofu, ehlanganiswe nezikhonkwane zokuphepha, futhi isakhiwo silula futhi sithembekile. Ngesikhathi esifanayo, ungqimba ngalunye lungalungiswa ngokukhululekile phezulu naphansi ngezinyathelo ezingu-75mm noma ezingu-50mm; Phakathi kwabo, ukuphakama kwekholomu eyodwa kungafinyelela amamitha angu-12, futhi ipulasitiki yamashalofu e-pallet inkulu kakhulu. Amashalofu esikhunta, amashalofu e-attic, amashalofu e-warehouse anezinhlangothi ezintathu, njll angakhiwa ngesisekelo samashalofu e-pallet, angenziwa futhi abe amashalofu akhethekile emiphongolo kawoyela. Akukhona lokho kuphela, ishalofu le-cross beam lingabuye lifakwe ama-laminates, okungaba amapuleti ensimbi, amapuleti aminyene e-ammonia noma amanetha egridi, ukuze abambisane nokusetshenziswa kwamathreyi anobukhulu obuhlukahlukene. Ishalofu lohlobo lwe-beam lingakwazi ukunquma izidingo zomthwalo wesendlalelo ngosayizi wekholomu ne-beam. Inezici zesikhashana esikhulu se-inertia, umthamo wokulayisha ungqimba oqinile kanye nokumelana nomthelela oqinile. Umthwalo wesendlalelo esikhulu sesendlalelo ngasinye ungafinyelela ku-5000kg/ ungqimba ngaphansi komklamo ohlobene. Isici esikhulu kunazo zonke seshalofu lohlobo lwe-beam ukuthi lingakwazi ukuthuthukisa ukuphakama kwesitoreji se-warehouse futhi lithuthukise izinga lokusebenzisa isikhala sempahla. Isetshenziswa kabanzi kumodi yokugcina isitoreji se-pallet kanye nokufinyelela kwe-forklift. Ishalofu le-crossbeam linezindleko eziphansi, kulula ukulifaka nokusebenza, ukulithola kalula indawo, lilungele noma yimaphi amathuluzi okuphatha, asetshenziswa kabanzi ekukhiqizeni, ekusetshenzisweni kwezinkampani zangaphandle, izikhungo zokusabalalisa neminye imikhakha, futhi ifanele ukugcinwa kwezinto ezihlukahlukene. izinhlobo zezimpahla. Ama-Hagerls azohlinzeka ngamashalofu e-crossbeam emininingwane ehlukene ukuze akhethwe ngokuvumelana nezimo zangempela zokusetshenziswa zabasebenzisi: izidingo zomthwalo wephalethi, usayizi wephalethi, indawo yangempela yokugcina impahla, kanye nokuphakama kwangempela kwama-forklift.

Ukuhlukaniswa kweshalofu le-Beam

Sekuyiminyaka engaphezu kwengu-20, indawo yokugcina i-hagerls yenza iphrojekthi yeshalofu yeshalofu ezenzakalelayo. Ngokwezidingo zamakhasimende ayo, inkampani yethu ayikwazi ukukhiqiza kuphela amashalofu esindayo esindayo, kodwa futhi ikhiqize amashalofu e-beam, amashalofu e-pallet beam, amashalofu amancane omugqa we-pallet, amashalofu okugcina esindayo, amashalofu e-mobile beam, amashalofu e-beam ahoxiswayo, njll.

Umgomo wokusebenza weshalofu le-cross beam

Ishalofu elisindayo le-crossbeam livamile ezinhlelweni zamashalofu esitoreji sasekhaya ahlukahlukene. Okokuqala, kuyadingeka ukwenza umsebenzi we-unitization, okungukuthi, ukupakishwa kwezimpahla nesisindo sazo nezinye izici, futhi unqume uhlobo, ukucaciswa, usayizi, isisindo somthwalo owodwa kanye nokuphakama kwe-pallet (isisindo). wezimpahla zokwesekwa okukodwa ngokuvamile ungaphakathi kuka-2000kg), bese unquma ubude, ukujula kanye nesikhala songqimba seshalofu leyunithi, futhi unqume ukuphakama kweshalofu ngokuya ngobude obusebenzayo bonqenqema olungezansi lwe-truss yophahla lwempahla kanye nokuphakama kwemfoloko. weloli ye-forklift. Ubude bamashalofu amayunithi ngokuvamile bungaphakathi kwe-4m, ukujula kungaphakathi kwe-1.5m, ukuphakama kwezindawo zokugcina izimpahla ezisezingeni eliphansi nezisezingeni eliphakeme ngokuvamile kungaphakathi kwe-12M, futhi ukuphakama kwezindawo zokugcina impahla ezisezingeni eliphakeme ngokuvamile kungaphakathi kwama-30m (lezo zindawo zokugcina impahla zisebenza ngokuzenzakalelayo. izindawo zokugcina izimpahla, kanye nobude obuphelele bamashalofu buhlanganiswe nezigaba eziningana zamakholomu ngaphakathi kwe-12m). Ezinqolobaneni ezinjalo, izindawo zokugcina izimpahla ezisezingeni eliphansi nezisezingeni eliphezulu ikakhulukazi zisebenzisa ama-forklift ebhethri ahambayo, ama-forklift wesisindo sebhethri ebhalansi, kanye nama-forklift ezindlela ezintathu ukuze afinyelele imisebenzi. Uma amashalofu ephansi, izitaki zikagesi nazo zingasetshenziswa, futhi izindawo zokugcina impahla ezisezingeni eliphezulu zisebenzisa izitaki ukuze kufinyelelwe kuzo. Lolu hlobo lwesistimu yeshalofu lunezinga eliphezulu lokusebenzisa indawo, ukufinyelela okuguquguqukayo nokulula, okulekelelwa ukuphathwa kwekhompyutha noma ukulawula, futhi ngokuyisisekelo lingahlangabezana nezidingo zohlelo lwesimanje lokuthutha.

Indlela yokuklama ubude, ububanzi, ukuphakama, ukudlula, njll. kweshalofu le-cross beam?

Idizayini yobude yeshalofu le-cross beam:

(1) Qonda ukucaciswa kwephalethi.

(2) Ngokuvamile, amaphalethi amabili aklanyelwe ukubekwa esitezi ngasinye, futhi isikhala phakathi kwamaphalethi singu-70-100mm (isikhala phakathi kwamashalofu aphezulu singu-100mm, futhi isikhala phakathi kwamashalofu aphansi singaba ngu-70mm). Uma ubude be-pallet buncane (njenge-800mm), ama-pallets amathathu angabekwa kungqimba ngalunye.

(3) Ifomula: l= ubude bephalethi *2 (70-100) *3 (inani lezikhawu)

Idizayini yobubanzi beshelufu lohlaka:

(1) Ibalwa ngokusekelwe kusayizi wangempela wobubanzi bephalethi.

(2) Uma ikhasimende lidinga ukwengeza imishayo ye-span, ukubeka amapuleti ensimbi, amapulangwe nezinye izesekeli, ububanzi beshalofu bungaklanywa ukuthi bulingane nobubanzi bephalethi.

(3) Ifomula: d= ububanzi bephalethi 200mm.

Idizayini yobude beshelufu le-cross beam:

(1) Ubude obuthile buncike endaweni yokugcina impahla yekhasimende kanye nezici zokuphakama kokuphakama ngeforklift.

(2) Ubude kufanele kube ukuphindaphinda okubalulekile okungama-75mm. Uma kungenjalo, thatha inani elifanayo.

(3) Ifomula: H (ukuphakama kwesitezi) = ukuphakama kwempahla eyi-150 (ikhefu) ubude be-beam (ukuthwala okuhlukile kanye nokucaciswa).

Ukudlula: nquma ukudlula kwe-forklift ngokusho kokusebenza kwe-forklift (njengokuhamba komsebenzi, ukuphakamisa, ukulayisha, njll.).

Ishalofu le-Hegerls crossbeam lihlukile kwamanye amashalofu asindayo

Umehluko omkhulu phakathi kwamashalofu e-crossbeam akhiqizwa umenzi wesitoreji se-Hergels nabanye abakhiqizi beshalofu lokugcina ukuthi anokumelana nokugqwala okuphezulu. Ukusetshenziswa kwensimbi ekhethekile engezwe nge-Al, Mg, Ni, Cr namanye ama-alloys emikhiqizweni elwa nokugqwala kwamashalofu e-Hagrid anti-corrosion kungalandelelwa emuva ekuqaleni kwekhulu lama-21, futhi inhloso enkulu ukuthuthukisa ukugqwala. ukumelana kwamapuleti ensimbi. Ukwelashwa okungaphezulu kwamashalofu alwa nokugqwala kudlala indima ebalulekile kuyo yonke inqubo yokukhiqiza. Ukulawulwa okuqinile kokucutshungulwa kwangaphambili, ukulungisa amaphutha kwemishini ekucutshungulweni, ukucutshungulwa kwangemuva, ukudlula ngaphezulu kanye nezindlela zokumboza kungaqinisekisa ukusebenza kokunqanda ukugqwala kwemikhiqizo yeshalofu. Ngesikhathi sokufakwa kamuva kwemikhiqizo yeshalofu, ukusetshenziswa kwezinye izesekeli zeshalofu nakho kuqinisekisa ukusebenza kokunqanda ukugqwala kwemikhiqizo ngokwezinga elithile. Lolu hlobo lwezinto zeshalofu ezilwa nokugqwala lunokumelana nokugqwala okungcono. Ukwanda kokuqukethwe kwe-Al, Mg, Ni kanye ne-Cr phakathi kwebanga elithile kwenza ukumelana nokugqwala kwepuleti lensimbi izikhathi eziningana ukuya ngaphezu kokuphindwe kashumi ngaphezu kwalokho kwepuleti elivamile. Ngenxa yokwelashwa kwe-anti-corrosion yezinqubo ze-pre machining, i-intermediate kanye ne-post machining, izinto zokusetshenziswa zihlala zodwa. Okokugcina, ukukhethwa kwezingubo zokulwa nokubola kanye nokwelashwa kwezinqubo ezikhethekile kuqinisekisa ukuthi ukusebenza kwe-anti-corrosion yezinto ezibonakalayo kungcono kakhulu kunemikhiqizo yendabuko. Ngesikhathi esifanayo, ukusetshenziswa kwamashalofu avimbela ukugqwala embonini yokwelapha imfucuza eyingozi kuye kwanciphisa kakhulu izindleko zokufakwa kwempahla engaguquki yamabhizinisi emfucumfucu eyingozi, futhi kwanciphisa nokuphathwa kanye nezindleko zesikhathi ezilethwa amabhizinisi ngokufaka amashalofu esikhundleni.

Ukusetshenziswa kwezinto ezingavuthiwe zokulwa nokugqwala kuye kwabeka isisekelo esiqinile sokumelana nokugqwala kweshalofu, kodwa isinyathelo sokuqala kuphela esiqediwe sokwakhiwa kweshalofu elilwa nokugqwala. Izinyathelo zokulwa nokugqwala enqubweni yomshini wokukhiqiza nazo zibaluleke kakhulu. Imikhiqizo yethu elwa nokugqwala ilawula ngokuqinile ukuvikelwa kwe-substrate ngesikhathi sokucutshungulwa, ukuze i-substrate ihlale yodwa ezintweni zangaphandle. Ngemuva kokucubungula, inqubo yokwelashwa kwangaphambili yomkhiqizo ayikwazi kuphela ukuqinisekisa ukuhlanzeka kwe-substrate surface, kodwa futhi yakha ifilimu yokuzivikela eminyene endaweni engaphansi. Le filimu evikelayo ingakwazi ukuhlukanisa ukungcola kwangaphandle ngaphambi kokumboza futhi isize i-coating imunce. Ihlose inkinga yokuvala uphawu, imikhiqizo yethu yamukela inqubo yesibili yokwemboza yokumelana nokugqwala okuphezulu, okuthuthukisa kakhulu ukubekwa uphawu kwentonga. Izesekeli zokunqanda ukugqwala ezisetshenziswa kwinqubo yokufaka kanye nokusebenza nokugcinwa kwansuku zonke ngemva kokusetshenziswa ziqinisekisa ukumelana nokugqwala komkhiqizo. Inkampani yethu iphinde yenza ngokuhlanganyela umklamo wokubukisa we-dip galvanizing ngemuva kokufaka i-Q235 ne-Q345 ngezinto ezilwa nokugqwala, kanye nomklamo wokubukisa wokwelashwa okulwa nokugqwala kanye nokukhetha kokumboza ekucubunguleni amabhizinisi okwelapha imfucuza eyingozi, ahlangabezana nezidingo. yokumelana nokugqwala okuphezulu kanye nokuphathwa okujwayelekile embonini yokwelapha imfucuza eyingozi.

Misa ithimba labaphathi bamakhasimende elikhethekile le-hegerls yamakhasimende, okuhlanganisa ukuthengisa, i-R & D, ukufakwa nokugunyazwa, kanye nethimba lesevisi yokusebenza nokunakekela. Ukuze uthole ukulawulwa kwekhwalithi, ukuhlela ukukhiqiza nokuthunyelwa komkhiqizo, i-hegerls ihlela abasebenzi abakhethekile ukuze balandelele. Ithimba lamakhasimende akwa-Hegerls livakashela amakhasimende okungenani kanye ngonyaka ukuze liqonde kusenesikhathi ukusetshenziswa kwemikhiqizo nezimfuno zabasebenzisi mayelana nokulethwa, ikhwalithi, ukusebenza nokugcinwa. Uma abasebenzisi bethola izinkinga noma bephakamisa ukuphikisa ngesikhathi sokusetshenziswa komkhiqizo, abakwa-hegerls bazothembisa ukufika kusayithi yekhasimende phakathi kwamahora angu-24 futhi benze uhlelo lokwelapha phakathi namahora angu-48.

Isikhathi sokuthumela: Jul-25-2022