Amashalofu asindayo okugcina, aziwa nangokuthi amashelufu e-cross beam, noma amashalofu esikhala sempahla, angawamashalofu ephalethi, okuwuhlobo oluvame kakhulu lwamashalofu ezinhlelweni zamashalofu okugcina asekhaya ahlukahlukene. Isakhiwo esihlanganiswe ngokugcwele ngesimo sekholomu ucezu + ugongolo mfushane futhi ngempumelelo. Izesekeli ezisebenzayo ezifana nokuhlukanisa, i-laminate yensimbi (i-wood laminate), isendlalelo se-wire mesh, isitimela somhlahlandlela wekheji yokugcina, i-rack tank yamafutha, njll. Hlangana nokugcinwa kwezimpahla ngendlela yamayunithi ahlukahlukene aqukethe okokusebenza. Ngakho-ke lapho amabhizinisi ngamanye kufanele asebenzise amashalofu asindayo ezindaweni zokugcina impahla, yiziphi izici okufanele zibhekwe? Manje, umenzi weshalofu lokugcina i-Hergels uzokwethula lona.

Ukuba khona kwamashalofu esindayo okugcina kuhlangabezana kakhulu nezidingo zokufinyelela ezinqolobaneni ezahlukene, izimpahla ezihlukene kanye nezimo ezahlukene zokugcina. Vele, iphinde ithuthukise ukusebenza kahle kwempahla kanye nokugcinwa kwempahla sekukonke, futhi inikeze izimo ezidingekayo zokusebenza okujwayelekile nokusebenza kahle kwamabhizinisi. Izakhiwo zamashalofu okugcina okusindayo zihlukile, imiphumela yangempela yokusebenza ihlukile, futhi izindleko zokuthenga nazo zihluke kakhulu. Amabhizinisi adinga ukukhetha idizayini eqondiwe kanye nokukhiqiza ngokuvumelana nezimo ezithile zokulondoloza, ahlanganise izici ezihlukahlukene kanye neziphakamiso zabakhiqizi bamashalofu okugcina.

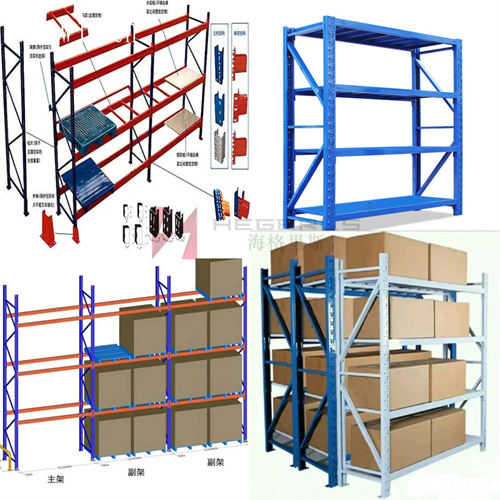

Isakhiwo seshalofu lesitoreji esindayo

Ishalofu esindayo lihlanganiswa ngamakholomu, imishayo, izintambo eziphambanayo, izinsimbi ze-diagonal kanye nama-self-locking bolts, okungavimbela ngokuphumelelayo ukungazinzi kweshalofu okubangelwa ukukhulula ama-bolts; Ugongolo luthatha ugongolo oluvaliwe olumise okuka-P olukhethekile; Isakhiwo sinezici ezilula futhi ezinokwethenjelwa, isisindo esincane, umthamo oqinile wokuthwala kanye nezindleko eziphansi; Lapho i-clamp yekholomu ixhunywe nekholomu, ifakwe iphinikhodi yokuphepha eklanyelwe ngokukhethekile, engaqinisekisa ukuthi ugongolo ngeke liwe ngaphansi komthelela wamandla angaphandle; I-laminate ithatha i-strip laminate eyenziwe ngamazwe ngamazwe, enezici zokuthwala okuqinile, ukumelana nokugqoka, ukushintshwa okulula kanye nezindleko eziphansi zokunakekela.

Idizayini yeshalofu yesitoreji esindayo

Okokuqala, kuyadingeka ukwenza umsebenzi we-unitization, okungukuthi, ukupakishwa kwezimpahla nesisindo sazo nezinye izici, futhi unqume uhlobo, ukucaciswa, usayizi, isisindo somthwalo owodwa kanye nokuphakama kwe-pallet (isisindo). wezimpahla zokwesekwa okukodwa ngokuvamile ungaphakathi kuka-2000kg), bese unquma ubude, ukujula kanye nesikhala songqimba seshalofu leyunithi, futhi unqume ukuphakama kweshalofu ngokuya ngobude obusebenzayo bonqenqema olungezansi lwe-truss yophahla lwempahla kanye nemfoloko ephezulu. ukuphakama kweloli forklift. Ubude bamashalofu amayunithi ngokuvamile bungaphakathi kwe-4m, ukujula kungaphakathi kwe-1.5m, ukuphakama kwezindawo zokugcina izimpahla ezisezingeni eliphansi nezisezingeni eliphakeme ngokuvamile kungaphakathi kwe-12M, futhi ukuphakama kwezindawo zokugcina impahla ezisezingeni eliphakeme ngokuvamile kungaphakathi kwama-30m (lezo zindawo zokugcina impahla zisebenza ngokuzenzakalelayo. izindawo zokugcina izimpahla, kanye nobude obuphelele bamashalofu buhlanganiswe nezigaba eziningana zamakholomu ngaphakathi kwe-12m).

Isisetshenziswa serack esindayo sokugcina

Ezinqolobaneni ezinjalo, izindawo zokugcina izimpahla ezisezingeni eliphansi nezisezingeni eliphezulu ikakhulukazi zisebenzisa ama-forklift ebhethri ahambayo, ama-forklift wesisindo sebhethri ebhalansi, kanye nama-forklift ezindlela ezintathu ukuze afinyelele imisebenzi. Uma amashalofu ephansi, izitaki zikagesi nazo zingasetshenziswa, futhi izindawo zokugcina impahla ezisezingeni eliphezulu zisebenzisa izitaki ukuze kufinyelelwe kuzo. Lolu hlobo lwesistimu yeshalofu lunezinga eliphezulu lokusebenzisa indawo, ukufinyelela okuguquguqukayo nokulula, okulekelelwa ukuphathwa kwekhompyutha noma ukulawula, futhi ngokuyisisekelo lingahlangabezana nezidingo zohlelo lwesimanje lokuthutha. Isetshenziswa kabanzi ekukhiqizeni, ekusetshenzisweni kwezinkampani zangaphandle, izikhungo zokusabalalisa neminye imikhakha. Ayifanelekile kuphela ezinhlobonhlobo eziningi kanye nezimpahla ze-batch ezincane, kodwa futhi ifaneleka ezinhlobonhlobo ezincane nezimpahla ezinkulu ze-batch. Amashalofu anjalo asetshenziswa kakhulu ezindaweni zokugcina impahla ezisezingeni eliphezulu nasezindaweni zokugcina impahla ezisezingeni eliphezulu (amashalofu anjalo asetshenziswa kakhulu ezindaweni zokugcina impahla ezizenzakalelayo).

Ngakho-ke lapho amabhizinisi ngamanye kufanele asebenzise amashalofu asindayo ezindaweni zokugcina impahla, yiziphi izici okufanele zibhekwe?

isisindo net impahla kanye Pallets

Izimpahla ezisemashalofini okugcina esindayo ngokuvamile zibekwe emashalofini okugcina anamaphalethi ukuze kube lula ukuthuthwa nokugcinwa kwezimpahla ngama-forklift kagesi nezinye izinto zokusebenza. Ngakho-ke, isisindo esiphelele sama-pallets nempahla siyisixhumanisi esibalulekile sabasebenzi bokuklama ukubala umthwalo odingekayo womthwalo wengqimba ngayinye yamashalofu okugcina. Kuphela ngokunquma ngokunembile ukuthwala umthwalo wamashalofu okugcina kungaqinisekiswa isici sokuphepha samashalofu okugcina.

usayizi wethreyi nokucaciswa komkhiqizo

Ngokwempahla egciniwe ehlukene, amaphalethi akhethiwe nawo azoba nomehluko othile. Isibonelo, indawo ephelele yama-pallets izodlula indawo yonke yezimpahla, futhi indawo yonke yezimpahla izodlula indawo ephelele yama-pallets. Ngalesi sikhathi, izisebenzi zokuklama kufanele zibale ubude, ububanzi nokuphakama kwengqimba ngayinye yamashalofu okugcina ngokusho kwendawo ephelele yalezi zibili, ukuze kuqinisekiswe ukuthi kulula ukusetshenziswa kwamashalofu okugcina.

Isilinganiso sobubanzi bobude obuphelele bendawo yokugcina izimpahla kanye neforklift kagesi ithuthukisa isilinganiso sobubanzi bobude

Isilinganiso sobubanzi bobude besendlalelo ngasinye singanqunywa ngokwesilinganiso sobubanzi bobude bezimpahla kanye nethreyi yokudonsa, kodwa uma isikhala sasendlini seshede singanele, noma isilinganiso sobubanzi bobude beforklift kagesi asanelanga, ishalofu eliphezulu lokugcina impahla. ngeke isebenziseke. Ngakho-ke, kudingekile kakhulu kubasebenzi bohlelo lokuklama kahle ukuphakama kwendawo yokugcina impahla kanye nesilinganiso sobubanzi bobude be-forklift kagesi.

Imodeli, ukucaciswa kanye nemingcele eyinhloko ye-forklift kagesi

Endaweni yokugcina izinto ezisindayo, kuyadingeka ukugcina indawo ephephile yezinto zokusebenza kanye nezinsiza ezifana nama-forklift kagesi anobubanzi obanele, kanye nokuhlinzeka ngamandla ezidingweni zokusebenza kwemishini efana nama-forklift kagesi. Ama-forklift kagesi ahlukene nawo ahlukile ekusebenzeni, ngakho-ke ibeka ukuthi umklami kufanele abe yinkosi yemodeli, ukucaciswa kanye nemingcele eyinhloko yemishini efana nama-forklift kagesi, ukuze aklame isixazululo esinengqondo sama-racks omsebenzi osindayo endaweni yokugcina impahla.

ubunjiniyela kanye nezimo zokwakha endaweni yokugcina

Ezindaweni zokugcina izimpahla ezahlukene, izakhiwo zamapayipi omlilo, iminyango yokufinyelela umlilo, izigxobo zokwakha zobunjiniyela, izicabha, amaphaseji okungezona ezezimoto nokunye angeke kufane ncamashi. Ngenxa yalokhu, kuphela ngokuqonda izimo zesayithi kuqala, singakwazi yini ukwaba ngendlela ephumelelayo nangokunengqondo indlela yokuhlunga yamashalofu okugcina, ukuze sithuthukise izinga lokusebenzisa indawo yasendlini endaweni yokugcina izimpahla futhi siqinisekise ukukhuliswa kwenani lekhasimende kanye nenzuzo.

Uhlelo oluzwakalayo kanye nomklamo weshelufu elisindayo kufanele licabangele izinto eziningi eziyindilinga, futhi lihlanganise izidingo ezithile zohlelo lwamakhasimende, ukuze ukuhlaziya ukuthi kungenzeka yini kanye nokusebenza kohlelo kufezeke. Umkhiqizi wamashalofu okugcina e-Hagerls ungomunye wabakhiqizi abangochwepheshe abasebenza ngokukhethekile ekuhleleni, ekuklameni, ekukhiqizeni nasekufakweni kwamashalofu ahlukahlukene kanye nezinhlelo zokuthutha. Inkampani yethu inamandla obuchwepheshe aqinile, okokusebenza okudidiyelwe kokukhiqiza, ithimba lokufakela elivuthiwe kanye nesistimu yesevisi ephelele yangemva kokuthengisa. Inkampani yethu isebenza ngokuhambisana ngokuqinile nezinkambiso zemboni, ihlale idonsa ubuchwepheshe obuphambili bezinhlelo zempahla yasekhaya neyangaphandle, futhi ihlale ithuthukisa imikhiqizo emisha ngokuhlanganiswa nesimo sangempela samabhizinisi asekhaya nawakwamanye amazwe. Le nkampani ikhetha izinto zokusetshenziswa ezisezingeni eliphezulu futhi izibophezele kuzo zonke izinhlobo zamashalofu esindayo angaguquguqukayo futhi aqoqwe, ngokusebenzisa amashalofu, amashalofu e-shuttle, amashalofu e-cantilever, amapulatifomu e-attic, isitoreji esindayo seshelufu, amashalofu okugcina asindayo, amashalofu epulatifomu e-attic, amashelufu esindayo, Amashalofu asindayo e-warehouse, amashalofu okugcina amapulangwe, amashalofu esitoreji se-attic, amashalofu e-attic, amashalofu e-cantilever, amashalofu adonsela phansi, amashalofu ane-laminate, amashalofu asindayo aphakathi nendawo nesekondari Ukuklama, ukwakhiwa nokufakwa kwamashalofu akhethekile, amashalofu ama-roller, amashalofu ane-laminated kanye nemishini esekelayo emotweni ye-4S. izitolo; Akukhona lokho kuphela, muva nje, inkampani yethu iphinde yasungula ngokuzimela uhlelo lwamarobhothi ebhokisi lomcebo, okuhlanganisa i-haipik ye-treasure irobhothi, inqwaba yokushaja ehlakaniphile, idivayisi yokugcinwa kwempahla eyenziwe ngokwezifiso, indawo yokusebenzela enemisebenzi eminingi kanye nesiteji sokuphatha esihlakaniphile se-haiq, ukusiza ukuphathwa kwe-warehouse automation. Uhlelo lwamarobhothi e-Kubao luhlanganisa: I-Carton picking irobhothi herls a42n, ukuphakamisa amarobhothi ama-herls A3, i-double deep bin robot herls a42d, i-telescopic lifting bin robot herls a42t, i-laser slam multi-layer bin robot herls a42m slam, multi-layer bin machine human herls A42 , i-dynamic wide elungisa i-bin irobhothi herls a42-fw. Irobhothi le-Kubao linomsebenzi wokukhetha nokuphatha okuhlakaniphile, ukuzulazula okuzenzakalelayo, ukugwema izithiyo ezisebenzayo kanye nokushaja okuzenzakalelayo. Inezici zokuzinza okuphezulu nokusebenza ngokunemba okuphezulu. Ingangena esikhundleni sokufinyelela okuphindaphindiwe, okudla isikhathi nokusindayo kokufinyelela nokusingatha umsebenzi, ibone ukucosha “impahla kubantu” okuphumelelayo nokukhaliphayo, futhi ithuthukise kakhulu ukuminyana kwesitoreji nokusebenza kahle kwezandla kwendawo yokugcina impahla. Amashalofu okugcina, okokugcina kanye namarobhothi okugcina ahlakaniphile akhiqizwa abakwaHergel asetshenziswa kabanzi ekukhiqizeni, ekuphatheni nasekugcineni, emithini, ezitolo ezinkulu ezigcina izinto, imitapo yolwazi nezinye izimboni. Imikhiqizo namasevisi ahlanganisa cishe izifundazwe ezingu-30 kanye nezifunda ezizimele e-China. Imikhiqizo ithunyelwa eYurophu, eMelika, eMpumalanga Ephakathi, eLatin America, eNingizimu-mpumalanga ye-Asia nakwamanye amazwe nasezifundeni, futhi yenze impumelelo emangalisayo phesheya kwezilwandle, Ikakhulukazi, ukuhlanganiswa okuphelele kwemishini yokuhlela nokuklama kwephrojekthi yokugcina impahla enezinhlangothi ezintathu kanye Logistics park.

Isikhathi sokuthumela: Aug-04-2022