Ukuzuza ekuthuthukisweni okusheshayo kwe-e-commerce, kunesidingo esinamandla sokuzenzakalelayo kwe-warehousing kokubili ngaphakathi nangaphandle. Ikakhulukazi eminyakeni yamuva nje, ngenxa yokukhuphuka kwezindleko zabasebenzi, izindawo zokugcina izimpahla ezinkulu ezihlukahlukene nezikhungo zokuhlunga ekhaya naphesheya ziye zandisa imizamo yazo ekwakhiweni kwempahla okuzenzakalelayo. Kulo mongo, izixazululo ezisekelwe kuthreyi ezingafinyelela isitoreji esiminyene, ukusetshenziswa kwendawo, kanye nokuhlela okuvumelana nezimo, ikakhulukazi ngezimoto ezihlakaniphile ezinendlela emine, seziqalile ukuvela endaweni yokugcina impahla ehlakaniphile.

Kumongo wamabhizinisi akhiqizayo, njengoba amabhizinisi aphathekayo abhekana nezinselele ezifana nokuhlukahluka kwesidingo, ukugcwaliseka kwe-oda lesikhathi sangempela, kanye nokusheshisa ukuphindaphinda imodeli yebhizinisi, izimfuno zamakhasimende zezixazululo zezokuthutha zivame ukuguquguquka futhi zibe ubuhlakani. Ngokusekelwe kulo mkhuba, u-Hebei Woke wethule i-Hagrid HEGERLS i-pallet ehlakaniphile ye-4 way shuttle, egcwalisa igebe kuzixazululo eziguquguqukayo emkhakheni wokuphatha i-pallet ngaphambilini. Ezimakethe zanamuhla, amashalofu ephalethi abe uhlobo oluvame kakhulu lwamashalofu okugcina asetshenziswa ezindaweni zokugcina impahla zezimboni, izikhungo zempahla, izikhungo zokusabalalisa, nezinye izimo.

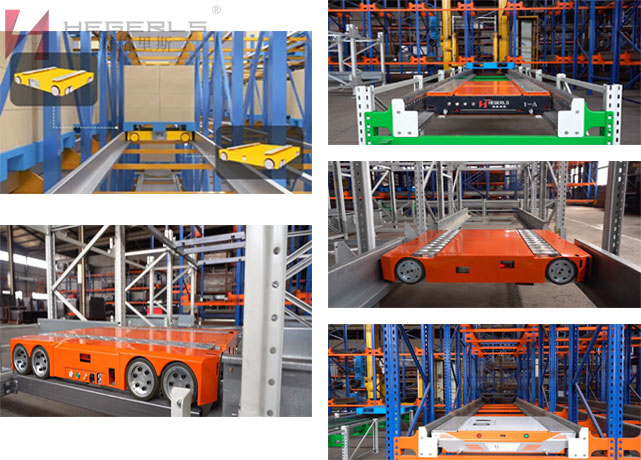

I-Hagrid HEGERLS ehlakaniphile yethreyi yemoto ye-four-way shuttle car ihlanganisa imoto ye-four-way shuttle, i-hoist ezinikele, isistimu yeshalofu, isistimu yezinsiza (okuhlanganisa isiteshi sokushaja, isidluliseli, isilawuli kude, inethiwekhi, nesistimu yokulawula ugesi), kanye HEGERLS uhlelo lwesoftware lokuhlela. Ngenxa yokuzibandakanya kokuhlelwa kwezimoto eziningi nomsebenzi wokuhlanganyela onemishini ehlobene njengamakheshi ohlelweni lwezimoto ezinendlela emine, ikhono lesofthiwe yokuhlela lizoba nomthelela obalulekile ekusebenzeni kahle kwesistimu. I-Hagrid HEGERLS uhlobo lwethreyi ehlakaniphile yohlobo lwe-4-way shuttle inezinzuzo ezinkulu eziyisithupha: “i-ultra-thin”, “ultra fast”, “ultra safe”, “ukubekezela isikhathi eside”, kanye “nokuhlelwa kweqoqo elikhulu kakhulu”, okungathuthuka kakhulu. ukusebenza kahle kokukhiqiza kwamabhizinisi. Leli robhothi elihambahambayo elizimelayo elingasebenza emashalofini lingaqhubeka lithuthukise izinga lokusetshenziswa kwendawo yokugcina izimpahla ngo-30% uma kuqhathaniswa nezixazululo ezizenzakalelayo zempahla. Ngesikhathi esifanayo, i-HEGERLS ehlakaniphile yethreyi ye-four way shuttle car inosayizi womzimba wamamilimitha angu-125 kuphela, isisindo samakhilogremu angu-300, futhi ihlangene futhi iqinile. Ingakwazi futhi ukuphatha izinto ezinesisindo esingamathani angu-1 kuye ku-1.5, ikwenze kube lula ukusebenza. Uma kuqhathaniswa ne-stacker engamathani ayi-10, ingakwazi ukonga ugesi ongaphezu kuka-50%. Uma kuqhathaniswa nezixazululo zendabuko ze-logistics automation, umzimba oguquguqukayo ungahamba phakathi kwamashalofu, ukhulise kokubili isivinini sokusebenza nokugcinwa kwesitoreji, okwenza ulungele ngokukhethekile ukugcinwa okubandayo, amandla amasha nezinye izimo zokusebenza.

Isixazululo esihlakaniphile sethreyi ye-Hagrid HEGERLS ayiyona isistimu yokugcina eminyene elula, kodwa iyisixazululo se-warehousing esihlakaniphile esivumelana nezimo kakhulu. Inzuzo yayo eyinhloko isekulawulweni okusabalalisiwe kwamadivayisi ahlukene. Kungenxa yalesi sici ukuthi abasebenzisi namabhizinisi bangahlanganisa kalula futhi basebenzise njengoba kudingeka, njengamabhulokhi wokwakha. Ngokungafani nezitaki ze-AS/RS, ezingasebenza kuphela ezindleleni ezingaguquki, uhlelo lwezimoto ezinendlela emine lusezingeni ngenxa yomkhiqizo walo wehadiwe, ongashintshwa ngemoto entsha nganoma yisiphi isikhathi uma kwenzeka ukungasebenzi kahle. Okwesibili, ukuguquguquka kubonakala “ekuhlakanipheni okuguquguqukayo” kwalo lonke uhlelo, lapho abasebenzisi namabhizinisi bengandisa noma behlise inani lezimoto ezihamba ngezindlela ezine nganoma yisiphi isikhathi ngokwezinguquko ezinjengokukhula kwesizini nokukhula kwebhizinisi, ngaleyo ndlela kuthuthukiswe umthamo wokuthwala. Ngaphezu kwalokho, amadivaysi ahlukene ahlobene eduze neshejuli nama-algorithms, kuyilapho ukulawula okusabalalisiwe empeleni kukuyo yonke imoto, okuhambisana nobuchwepheshe beplathifomu yokulawula ye-AMR. Isu lokuhlela le-HEGERLS alikwazi ukulawula imoto ngayinye enendlela emine kuphela, kodwa futhi linikeze ama-algorithms wezinguquko kumthamo ongenayo noma ophumayo, ukwabiwa kwamandla okuthutha, ukulungiswa kwendawo yokugcina impahla, kanye nokwenza kahle kwendlela. Mayelana nokuhlelwa kwemishini ehlukile noma ukuthuthukiswa kokusebenza kahle kwesistimu, amandla amakhulu ayinhloko avela kusofthiwe, okuyinzuzo yochungechunge lomkhiqizo we-Hagrid. Ngaphezu kwalokho, ithreyi ye-Hagrid HEGERLS ehlakaniphile ye-four-way shuttle nayo inezinzuzo ezilandelayo:

1) Ukulawula okuhlakaniphile

Ukwenza ngcono ukusebenza kahle kokugcinwa kwezimpahla kanye nokusetshenziswa kwendawo yokugcina impahla. Ukuhlanganiswa kwesofthiwe yesistimu ye-WMS ne-WCS ne-ERP yebhizinisi, i-SAP, i-MES kanye nezinye isofthiwe yesistimu yokuphatha kungabuye kugcine umthetho wokuqala wezimpahla, futhi kuqede ukudideka noma ukusebenza kahle okuphansi kwezici zomuntu ekusebenzeni.

2) Intelligent layer switching

Ukusebenzisana ne-elevator, imoto ye-shuttle ingafinyelela imodi yokusebenza ephumelelayo yokuguqulwa kwesendlalelo esizenzakalelayo nesinembile; Bona ukusebenza kwendawo enezinhlangothi ezintathu. Lawula ngokunembile ukungena nokuphuma kwendawo ngayinye yokugcina ngaphakathi kwendawo yeshalofu lensimbi.

3) Ukuphathwa Kwendawo Dynamics

Izinqolobane zendabuko ziyizindawo nje zokugcina izimpahla, futhi ukugcinwa kwezimpahla kuwukuphela komsebenzi wazo, okuwuhlobo "lwesitoreji esimile". I-pallet four-way shuttle iyimishini yokuthutha ezenzakalelayo ethuthukisiwe engagcini nje ngokuvumela ukuthi izimpahla zigcinwe ngokuzenzakalelayo futhi zigcinwe endaweni yokugcina izinto ngokusho kolwazi oludingekayo, kodwa futhi zingaxhunywa ngokwemvelo ezinkambisweni zokukhiqiza ngaphandle kwendawo yokugcina impahla. Ukwenza kube lula ukwakhiwa kwezinhlelo zezokuthutha ezithuthukile futhi kuthuthukiswe izinga lokuphathwa kwebhizinisi.

4) Ukuthuthukisa ngokuphumelelayo ukusetshenziswa kwendawo yokugcina

Ukuminyana okuphansi kwezindawo zokugcina impahla kuholela ekusetshenzisweni okuncane kwendawo yonke nendawo yokugcina impahla. I-pallet four-way shuttle iloli igijima ngezindlela ezine kumzila omkhulu ngaphakathi kweshalofu, futhi ingaqedela ngokuzenzakalelayo ukusebenza ngaphandle kokuxhumana kwama-forklift nezinye izinto zokusebenza. Ngenxa yomthamo wethrekhi eyinhloko yeshalofu ibe mncane kunomthamo wesiteshi sokusebenza se-forklift, i-pallet four-way shuttle automation system ithuthukisa futhi ukusetshenziswa kwendawo yokugcina uma kuqhathaniswa nesistimu yeshalofu ye-shuttle evamile, Ingakhula cishe u-20% kuya ku-30%, okuyizikhathi ezingu-2-5 kunendawo yokugcina impahla evamile;

Njenge "isizukulwane esisha se-pallet flexible logistics solution", i-HEGERLS i-pallet ehlakaniphile ye-shuttle ye-four-way shuttle, ehlangene ne-software ye-HEGERLS yesikhulumi, ingakwazi ukufeza ukuhlakanipha kwe-swarm futhi isebenzise kakhulu indawo yokugcina impahla. Ngaphezu kwalokho, i-Hagrid HEGERLS i-pallet ehlakaniphile ye-shuttle ye-four-way shuttle izohlelwa ngokuvumelana ne-SKU ehlukene nezindawo zokugcina, futhi i-algorithm izoncoma ngokuzenzakalelayo izindawo zokugcina ezifanele lapho izinto zigcinwa endaweni yokugcina impahla, okuvumela ukuthi izimpahla zigcinwe ngokuvumelana nemithetho ethile futhi ukugwema ukuminyana ngesikhathi sokusebenza okuphuma kamuva, ukuthuthukisa ukusebenza kahle; Lapho ushiya inqolobane, i-algorithm iphinda ituse indawo efanelekile yokugcina impahla, futhi ibala izici ezihlukahlukene njengebanga, isithiyo emisebenzini, kanye nempahla yokugcina ukuze kuhlinzekwe ngendawo yokugcina efanele; Ingakwazi futhi ukuzuza ukubonwa kwempahla futhi ibuke kalula isimo sanoma iyiphi indawo yesitoreji ngokusebenzisa isixhumi esibonakalayo esinesithombe, esivumelana nezimo okuqinile, ukwethembeka okuphezulu, ukuhlakazeka okuqinile, nokuguquguquka okuphezulu.

Isikhathi sokuthumela: Apr-26-2023