I-automated-dimensional warehouse iyingxenye ebalulekile ye-logistics. Inezinzuzo eziningi ezinjengokonga umhlaba, ukunciphisa izinga labasebenzi, ukuqeda amaphutha, ukwenza ngcono izinga lokugcinwa kwezinto ezishintshayo nokuphatha, ukuthuthukisa izinga labaphathi nabasebenza ngogesi, ukunciphisa ukulahleka kwesitoreji nezokuhamba, ukunciphisa ngempumelelo ukusilela emuva kwemali yokusebenza, kanye nokwenza ngcono ukusetshenzwa. ukusebenza kahle, Ngesikhathi esifanayo, indawo yokugcina impahla enezinhlangothi ezintathu ezizenzakalelayo exhunywe nohlelo lwemininingwane yokuphathwa kwekhompyutha yezinga lemboni futhi exhumene eduze nolayini wokukhiqiza iyisixhumanisi esibalulekile se-CIMS (I-Computer Integrated Manufacturing System) kanye ne-FMS (uhlelo lokukhiqiza oluguquguqukayo). Futhi kuwuhlelo olugcina ngokuzenzakalelayo futhi lukhiphe izinto zokusebenza ngaphandle kokungenelela okuqondile okwenziwa ngesandla. Kungumkhiqizo wobuchwepheshe obuphezulu bokuthuthukiswa komphakathi wezimboni zesimanje, futhi kubalulekile ukuthi amabhizinisi athuthukise ukukhiqiza Ukwehliswa kwezindleko kudlala indima ebalulekile.

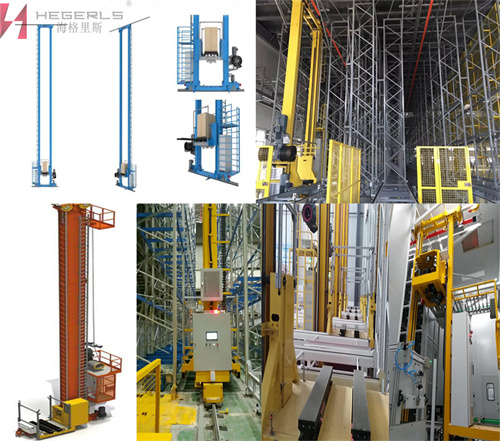

Eminyakeni yamuva nje, ngokuthuthuka okuqhubekayo kokukhiqizwa nokuphathwa kwamabhizinisi, ayanda amabhizinisi ayabona ukuthi ukuthuthukiswa nokuhluzeka kwesistimu yezokuthutha kubaluleke kakhulu ekuthuthukisweni kwamabhizinisi. Isitaki siyinto ebaluleke kakhulu yokuphakamisa nokupakisha endaweni yokugcina impahla enezinhlangothi ezintathu. Ingakwazi ukuthutha impahla isuka endaweni eyodwa iye kwenye ngokusebenza ngesandla, ukusebenza kwe-semi-automatic noma ngokusebenza okuzenzakalelayo okugcwele. Ingakwazi ukuya emuva naphambili emzileni ozishintshayo onezinhlangothi ezintathu futhi igcine izimpahla endleleni yokungena egunjini lempahla; Noma ngokuphambene nalokho, khipha izimpahla endaweni yezimpahla futhi uzihambise lapho uwela khona umzila, okungukuthi, isitaki siyisitimela noma i-trolley engenamkhondo efakwe izinto zokuphakamisa. I-stacker ifakwe injini yokushayela isitaki ukuze sinyakaze futhi siphakamise i-pallet. Uma isitaki sesithole indawo edingekayo yempahla, singaphusha ngokuzenzakalelayo noma sidonse izingxenye noma amabhokisi ezimpahla angene noma aphume endaweni yokubeka. I-stacker inenzwa yokubona ukunyakaza okuvundlile noma ukuphakama kokuphakamisa ukubona indawo nokuphakama kwesikhala sempahla, Ngezinye izikhathi ungafunda negama lezingxenye ezisesitsheni kanye nolunye ulwazi lwezingxenye ezifanele.

Ngokuthuthukiswa kobuchwepheshe bokulawula ikhompiyutha kanye ne-othomathikhi ye-auto-dimensional arehouse, ukusetshenziswa kwe-stacker kuya ngokuya kubanzi, ukusebenza kwezobuchwepheshe kungcono futhi kungcono, nokuphakama nakho kuyanda. Kuze kube manje, ukuphakama kwe-stacker kungafinyelela ku-40m. Eqinisweni, uma kungavinjelwa ukwakhiwa kwe-warehouse kanye nezindleko, ukuphakama kwe-stacker kungavinjelwa. Ijubane lokusebenza le-stacker libuye lithuthuke njalo. Njengamanje, isivinini sokusebenza esivundlile se-stacker sifinyelela ku-200m / min (i-stacker enomthwalo omncane isifinyelele ku-300m / min), ijubane lokuphakamisa lifika ku-120m / min, futhi ijubane le-telescopic lemfoloko lifika ku-50m. / imiz.

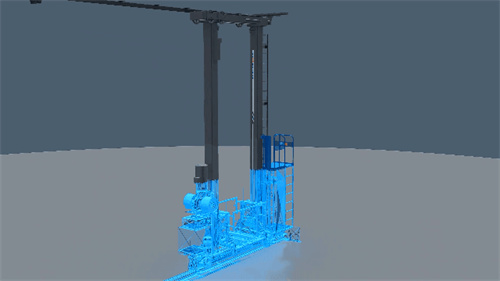

Ukwakhiwa kwe-stacker

Isitaki sakhiwe ngohlaka (uhlaka olungaphezulu, ugongolo olungezansi kanye nekholomu), indlela yokuhamba evundlile, indlela yokuphakamisa, iplatifomu yempahla, imfoloko kanye nesistimu yokulawula kagesi. Imininingwane imi kanje:

ifreyimu

Uhlaka luwuhlaka oluwunxande olwakhiwe ngogongolo olungaphezulu, amakholomu angakwesokunxele nangakwesokudla kanye ne-beam ephansi, esetshenziselwa kakhulu ukuthwala. Ukuze kube lula ukufakwa kwezingxenye futhi kuncishiswe isisindo se-stacker, imishayo engaphezulu nephansi yenziwe ngensimbi yesiteshi, futhi amakholomu ayenziwe ngensimbi yesikwele. I-crossbeam engaphezulu ihlinzekwa ngesivalo sesitimela esibhakabhakeni kanye ne-buffer, futhi ugongolo olungezansi luhlinzekwa ngesivalo sesitimela esingaphansi.

Indlela yokusebenza

Umshini wokugijima uwumshini wokushayela wokunyakaza okuvundlile kwesitaki, ngokuvamile esakhiwe yinjini, ukuhlanganisa, amabhuleki, isinciphisi kanye nesondo elihambayo. Ingahlukaniswa ngohlobo olugijima phansi, uhlobo olusebenzayo oluphezulu kanye nohlobo lokugijima oluphakathi ngokuya ngezikhundla ezihlukene zomshini wokugijima. Uma uhlobo lokugijima phansi lwamukelwa, amasondo amane ayadingeka ukuze agijime eduze kwe-monorail ebekwe phansi. Ingaphezulu le-stacker liqondiswa amasethi amabili amasondo avundlile eduze kwe-I-beam egxilwe kugongolo olungaphezulu. Ugongolo olungenhla luxhunywe ngamabhawodi namakholomu, futhi ugongolo olungezansi lushiselwe ngensimbi yesiteshi kanye nepuleti lensimbi. Umshini wokushayela ohambayo, isondo le-master-slave motor, ikhabethe likagesi, njll. konke kufakwe kuyo. Izinhlangothi ezimbili ze-beam engezansi nazo zifakwe amabhafa ukuvimbela isitaki ukuthi singakhiqizi amandla amakhulu okungqubuzana ngenxa yokungalawuleki kuzo zombili iziphetho zomhubhe. Uma isitaki sidinga ukuthatha ijika, okunye ukuthuthukiswa kungenziwa kumzila wesitimela.

Indlela yokuphakamisa

Umshini wokuphakamisa umshini owenza inkundla yezimpahla ihambe iqonde. Ivamise ukwakhiwa ngenjini, ibhuleki, isinciphisi, isigubhu noma isondo kanye nezingxenye eziguqukayo. Izingxenye ezivame ukusetshenziswa eziguquguqukayo zihlanganisa intambo yensimbi yensimbi kanye neketango lokuphakamisa. Ngaphezu kwesinciphisi segiya elijwayelekile, isinciphisi segiya lezikelemu kanye nesinciphisi seplanethi siyasetshenziswa ngenxa yesidingo sesilinganiso esikhulu sesivinini. Iningi lamadivaysi okuhambisa amaketango okuphakamisa afakwe engxenyeni engenhla futhi ngokuvamile afakwe ama-counterweights ukunciphisa amandla okuphakamisa. Ukuze wenze umshini wokuphakamisa uhlangane, i-motor ene-brake ivame ukusetshenziswa. Iketango lixhunywe ngokuqinile nephalethi ngegiya elikukholomu. Ingxenye yokusekela yokuphakamisa eqondile iyikholomu. Ikholomu iwuhlaka lwebhokisi eline-primary anti distortion, futhi ujantshi womhlahlandlela ufakwa nhlangothi zombili zekholomu. Ikholomu iphinde ifakwe ngokushintsha kwesimo somkhawulo ophezulu naphansi nezinye izingxenye.

Imfoloko

Ikakhulukazi yakhiwe i-motor reducer, i-sprocket, idivayisi yokuxhuma iketango, ipuleti lemfoloko, isitimela esihambayo esiqondisayo, isitimela esingaguquki, i-roller bear kanye nezinye izinto zokumisa. Indlela yokwenza imfoloko iyindlela yokuphatha yokuthi isitaki sifinyelele ezimpahleni. Ifakwe kwi-pallet ye-stacker futhi inganwetshwa ngokuvundlile futhi ihoxiswe ukuze ithumele noma ikhiphe izimpahla ezinhlangothini ezimbili zegridi yempahla. Ngokuvamile, izimfoloko zihlukaniswa zibe izimfoloko zemfoloko eyodwa, izimfoloko eziphindwe kabili noma izimfoloko eziningi ngokwenani lezimfoloko, futhi izimfoloko eziningi zemfoloko zisetshenziswa kakhulu ukupakisha izimpahla ezikhethekile. Amafoloko ngokuvamile anezigaba ezintathu zomugqa wokuhlukanisa amafoloko, akhiwe ngemfoloko ephezulu, imfoloko emaphakathi, imfoloko ephansi kanye nerola yenaliti enomsebenzi oqondisayo, ukuze kuncishiswe ububanzi bomgwaqo futhi awenze ube nohambo olwanele lwe-telescopic. Imfoloko ingahlukaniswa ngezinhlobo ezimbili ngokuya ngesakhiwo sayo: imodi ye-gear rack kanye nemodi ye-sprocket chain. Umgomo we-telescoping wefoloko ukuthi imfoloko engezansi ifakwe kuphalethi, imfoloko ephakathi iqhutshwa ibha yegiya noma ibha ye-sprocket ukuze iye kwesokunxele noma kwesokudla ukusuka ekugxilweni kwemfoloko ephansi cishe ingxenye yobude bayo, futhi imfoloko engenhla inweba iye kwesokunxele noma kwesokudla isuka phakathi nendawo yemfoloko emaphakathi ngobude obungaphezu kwengxenye yobude bayo. Imfoloko engenhla iqhutshwa ngamaketanga amabili ama-roller noma izintambo zocingo. Ingxenye eyodwa yeketango noma intambo yocingo igxilile kwimfoloko engezansi noma i-pallet, kanti enye igxiliwe kwimfoloko engenhla.

Indlela yokuphakamisa kanye nephalethi

Umshini wokuphakamisa uhlanganisa ikakhulukazi ukuphakamisa i-motor (okubandakanya i-reducer), i-drive sprocket, i-drive chain, i-sprocket ephindwe kabili, i-lifting chain kanye ne-idler sprocket. Iketango eliphakamisayo liwuchungechunge lwerowu eliphindwe kabili elinesici sokuphepha esikhulu kuno-5. Lenza isakhiwo esivaliwe esine-sprocket engenzi lutho ku-pallet kanye nemishayo engaphezulu nephansi. Lapho isithuthuthu esiphakamisayo sishayela isondo leketango eliphindwe kabili ukuze lizungezise ochungechungeni lokushayela, iketango eliphakamisayo lizonyakaza, ngaleyo ndlela lishayele iplathifomu yokuphakamisa (okuhlanganisa nezimfoloko nezimpahla) ukuze ikhuphuke futhi yehle. I-motor ephakamisayo ilawulwa ukuguqulwa kwemvamisa ye-PLC ukugwema ukungezwani okweqile kuketango lokuphakamisa ekuqaleni kokuphakamisa nokuma. Iplatifomu yempahla yenziwe kakhulu ngensimbi eyisicaba futhi eshiselwe, esetshenziswa kakhulu ukufaka izimfoloko nezinye izinto zokuvikela ukuphepha. Ukuze uqinisekise ukunyakaza okuzinzile kwephalethi ukuya phezulu naphansi, amasondo angu-4 omhlahlandlela namasondo ama-2 aphezulu eduze kwekholomu afakwe ohlangothini ngalunye lwe-pallet.

Impahla kagesi nokulawula

Ngokuyinhloko ihlanganisa idrayivu kagesi, ukudluliswa kwesignali nokulawula isitaki. Isitaki samukela ulayini wokuxhumana oslayidayo ukuze uthole ugesi; Njengoba ukunikezwa kwamandla okushelelayo ukuxhumana nenkampani yenethiwekhi kulula ukuthi kuphazanyiswe imfuhlumfuhlu yamandla, imodi yokuxhumana ye-infrared ene-anti-interference enhle iyamukelwa ukushintshanisa ulwazi nekhompyutha kanye nezinye izinto zokusebenza zokugcina impahla. Izici zokusebenza zesitaki ukuthi kufanele zibekwe kahle futhi ziqondiswe, ngaphandle kwalokho zizothatha izimpahla ezingalungile, zilimaze izimpahla namashalofu, futhi zilimaze isitaki ngokwaso ezimeni ezibucayi. Ukulawula indawo yesitaki kusebenzisa indlela yokuqaphela ikheli ngokuphelele, futhi isitholi sebanga le-laser sisetshenziselwa ukunquma indawo yamanje yesitaki ngokulinganisa ibanga ukusuka kusitaki ukuya endaweni yesisekelo nokuqhathanisa idatha egcinwe ku-PLC kusengaphambili. Izindleko ziphezulu, kodwa ukwethembeka kuphezulu.

Idivayisi yokuvikela ukuphepha

I-Stacker iwuhlobo lwemishini yokuphakamisa, edinga ukugijima ngesivinini esikhulu emhubheni aphezulu nemincane. Ukuze kuqinisekiswe ukuphepha kwabasebenzi kanye nemishini, isitaki kufanele sifake i-hardware ephelele kanye nemishini yokuvikela ukuphepha kwesoftware, futhi kuzothathwa uchungechunge lwezinyathelo zokukhiya nokuvikela ekulawuleni ugesi. Amadivayisi ayinhloko okuvikela ukuphepha ahlanganisa ukuvikelwa komkhawulo wetheminali, ukuvikelwa kwe-interlock, isilawuli sokutholwa kwesimo esihle, isivikelo sokunqanyulwa kwentambo yesikhulumi sempahla, ukuvikela ukucisha, njll.

Ukunqunywa kohlobo lwesitaki: kunezindlela ezihlukahlukene zesitaki, okuhlanganisa isitaki se-monorail tonnel, isitaki esiphindwe kabili sikaloliwe, isitaki esijikelezayo somhubhe, isitaki sekholomu eyodwa, isitaki sekholomu ephindwe kabili, njll.

Ukunqunywa kwesivinini se-stacker: ngokuya ngezidingo zokugeleza kwendawo yokugcina impahla, bala isivinini esivundlile, isivinini sokuphakamisa kanye nesivinini semfoloko yesitaki.

Eminye imingcele nokucushwa: imodi yokubeka kanye nemodi yokuxhumana ye-stacker ikhethwa ngokuvumelana nezimo zesayithi le-warehouse kanye nezidingo zomsebenzisi. Ukucushwa kwe-stacker kungaba phezulu noma phansi, kuye ngesimo esithile.

Ukusetshenziswa kwesitaki se-warehouse esinezinhlangothi ezintathu esizenzakalelayo

*Naka ukugcina iphaneli yokusebenza ihlanzekile futhi ihlanzekile, futhi uhlanze uthuli, uwoyela nezinye izinto eziningi nsuku zonke.

*Njengoba isikrini sokuthinta kanye nezinye izingxenye zikagesi kuphaneli yokusebenza zonakaliswa kalula umswakama, sicela uzigcine zihlanzekile.

*Lapho uhlanza iphaneli yokusebenza, kutuswa ukuthi usebenzise indwangu emanzi ukuze usule, futhi unake ukuthi ungasebenzisi izinto zokuhlanza ezonakalisayo ezifana nebala likawoyela.

*Lapho uhambisa i-AGV, idrayivu kufanele iphakanyiswe kuqala. Uma idrayivu yehluleka ukuphakanyiswa ngenxa yezizathu ezithile, amandla e-AGV kufanele avaliwe. Kunqatshelwe ngokuphelele ukuhambisa i-AGV lapho idrayivu ivuliwe futhi idrayivu ingaphakanyiswa.

*Uma i-AGV idinga ukumiswa esimweni esiphuthumayo, inkinobho yezimo eziphuthumayo izosetshenziswa. Akuvunyelwe ukusebenzisa ukudonsa noma ezinye izindlela zokuphazamisa ukuphoqa inqola ye-AGV ukuthi ime.

*Akuvunyelwe ukufaka noma yini kuphaneli yokusebenza.

Ukugcinwa kwansuku zonke kwesitaki se-warehouse esinezinhlangothi ezintathu esizenzakalelayo

*Hlanza izinto eziningi noma izindaba zangaphandle ku-stacker nomgwaqo.

*Hlola ukuthi ingabe kukhona ukuvuza kukawoyela endaweni yokushayela, ukuphakamisa kanye nemfoloko.

*Hlola ukuma okume mpo kwekhebuli.

*Thola ukuguga kwesitimela esiqondisayo kanye nesondo lomhlahlandlela kukholamu.

*Hlanza amehlo okukhanya kwe-elekthronikhi / izinzwa ezifakwe kusitaki.

* Ukuhlolwa komsebenzi we-electronic optical eye / sensor efakwe ku-stacker.

*Bheka ukushayela kanye nokusebenza kwamasondo (ukugqokwa).

*Hlola izesekeli bese ubheka ukuthi isondo lokusekela liyonakele yini.

*Hlola ukuthi akukho mfantu endaweni yokushisela yoxhumo lwekholomu noxhumo lomshudo.

*Hlola ukuma okuvundlile kwebhande elinamazinyo.

*Hlola ukuhamba kwesitaki.

*Hlola ngeso lengqondo umsebenzi wokudweba wesitaki.

Ngokuthuthuka kokukhiqizwa kwezimboni zesimanje, endaweni yokugcina impahla enezinhlangothi ezintathu, ukusetshenziswa kwe-stacker kuzoba kubanzi, ikakhulukazi ekwenziweni kwemishini, ukukhiqizwa kwezimoto, imboni yendwangu, ujantshi, ugwayi, ezokwelapha nezinye izimboni, ngoba lezi zimboni zizoba ifaneleka kakhulu ukusetshenziswa kweshede ezenzakalelayo ukuze igcinwe. I-Hagerls iyibhizinisi eliphelele eligxile esixazululweni, ukuklama, ukukhiqiza kanye nezinsizakalo zokufakwa kwendawo yokugcina impahla ehlakaniphile kanye nempahla ehlakaniphile esekela imishini ezishintshayo. Inganikeza amakhasimende isitaki sekholomu eyodwa, isitaki sekholomu ephindwe kabili, isitaki esiphendukayo, isitaki sokunwebeka esikabili kanye nesitaki somgqomo nezinye izinhlobo zemishini. Ingakwazi ukwenza ngokwezifiso izinhlobo ezahlukene zemishini yesitaki ngokuya ngemikhiqizo ehlukahlukene, kungakhathalekile usayizi nesisindo.

Isikhathi sokuthumela: Aug-18-2022