I-Intelligent automated warehouse enezinhlangothi ezintathu iwumqondo omusha endaweni yokugcina impahla yanamuhla, futhi iyimodi yokugcina enezinga eliphezulu lobuchwepheshe okwamanje. Ikakhulu isebenzisa izinto ezisetshenziswayo ezinezinhlangothi ezintathu ukuze kutholakale ukulinganisa okuphezulu, ukuzenzela okuzenzakalelayo kwesitoreji kanye nokusebenza okulula kwendawo yokugcina impahla, enezinzuzo eziphezulu zezomnotho nezenhlalo. Njengamanje, ukuvela kobuchwepheshe obusha obuhlukahlukene kukhuthaze ukuthuthukiswa kwendawo yokugcina impahla enezinhlangothi ezintathu ezizenzakalelayo iye endaweni ehlakaniphe kakhulu futhi evumelana nezimo. Ngakho-ke uma ufuna ukusebenzisa lesi sitolo esizenzakalelayo esinezinhlangothi ezintathu, ungayakha kanjani?

Mayelana nama-hagerls warehousing

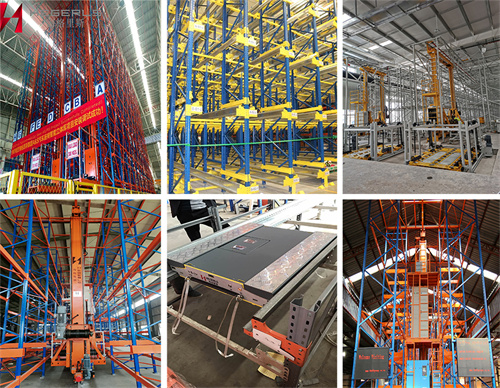

I-Hagerls iwuhlobo oluzimele oluyinhloko lwe-Hebei Walker metal products Co., Ltd. futhi yaqala ukungenelela ekuthengisweni nasekufakweni kwempahla yokugcina impahla kanye nempahla ngo-1998. Ngemva kweminyaka engaphezu kwengu-20 yentuthuko, isiphenduke ibhizinisi lobuchwepheshe obuphezulu obuhlanganisayo. ezihlakaniphile Logistics izixazululo kanye warehousing izinhlelo, ukuhlanganisa ishede futhi Logistics isikimu umklamo isikimu, ukukhiqizwa kwemishini kanye nezinsiza, ukuthengisa, ukuhlanganiswa, ukufakwa, ukuthunywa, ukuqeqeshwa kwabasebenzi bokuphatha inqolobane, insizakalo ngemva kokuthengisa, njll Amagatsha okuthengisa e-Xingtai, Bangkok, Thailand, Kunshan, Jiangsu naseShenyang. Inesizinda sokukhiqiza kanye ne-R & D esingamamitha-skwele angu-60000, imigqa yokukhiqiza ethuthukisiwe yomhlaba engu-48, kanye nabantu abangaphezu kuka-300 ku-R & D, ukukhiqiza, ukuthengisa, ukufakwa kanye nokuthengisa ngemva kokuthengisa, kuhlanganise nabantu abacishe babe ngama-60 abanochwepheshe abakhulu kanye nonjiniyela omkhulu. izihloko. Eminyakeni yamuva, inkampani iqinise ucwaningo nokuthuthukiswa kwemishini yokugcina okuzenzakalelayo. Imishini emibili yokugcina izinto ezizenzakalelayo, imoto eyisithuthuthu ehlakaniphile nesitaki se-intelligent plate warehouse, ziwine amalungelo obunikazi kazwelonke, futhi ngokuyisisekelo zaqeda uguquko olusuka ekuthumeleni imikhiqizo eyinhloko kwamanye amazwe luye ekuthumeleni kwamanye amazwe amasethi aphelele emishini ezenzakalelayo kanye nokwenza umsebenzi wokuqedela amaphrojekthi okugcina.

I-Hergels warehousing ibisebenza ngokuhambisana ngokuqinile nesistimu yekhwalithi ye-ISO9001, isistimu yezemvelo ye-ISO14001 nezinye izinhlelo zokuphatha ezempilo nokuphepha, futhi ibilokhu iphishekela imodi yokuphatha nokulawula yamazwe ngamazwe ukuze kuqinisekiswe izinga eliphezulu nokuzinza kwemikhiqizo yakwaHergels. U-Haggis ubelokhu enamathisele ukubaluleka okukhulu kumkhiqizo we-R & D kanye nokusungula izinto ezintsha, futhi unamalungelo obunikazi amaningana kazwelonke kumashalofu okugcina, izitaki, izinto ezihambisa impahla, izimoto ezihamba phambili, ukulawula nokuphatha indawo yokugcina impahla. Ikakhulukazi eminyakeni yamuva nje, umtapo wolwazi ohlakaniphile onezinhlangothi ezintathu okhiqizwe uHergels uye wathandwa amabhizinisi amakhulu ekhaya naphesheya. Manje vumela i-haggis herrls warehouse ikuyise ekuhlaziyeni okujwayelekile. Yakhiwa kanjani i-ASRS intelligent automated-dimensional warehouse?

1, Izinsiza eziyisisekelo ze-automated-dimensional arehouse

Izinsiza eziyisisekelo ze-automated-dimensional arehouse zihlanganisa ubunjiniyela bomphakathi kanye nezindawo zobunjiniyela bomphakathi, izinsiza zemishini kanye nezinsiza zikagesi.

1) Ubunjiniyela bomphakathi kanye nezinsiza

Ubunjiniyela bomphakathi kanye nezindawo zobunjiniyela bomphakathi ikakhulukazi zifaka isitshalo, uhlelo lokukhanyisa, umoya omncane kanye nesistimu yokufudumeza, uhlelo lwamandla, izindawo zokuphakelwa kwamanzi kanye nezindawo zokudonsa amanzi, uhlelo lokuvikela umlilo, ukuvikela umbani kanye nezindawo zokubeka phansi, izinsiza zokuvikela imvelo, njll.

2) Izinsiza zemishini

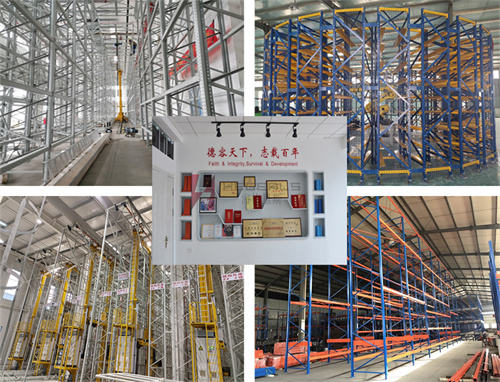

Izinsiza zemishini zingashiwo njengengxenye ebalulekile yendawo yokugcina impahla enezinhlangothi ezintathu ezizenzakalelayo. Kubandakanya amashalofu aphakeme kakhulu, ama-Road Stacking Cranes, imishini yokugcina impahla kanye neyokuthutha, njll. Phakathi kwazo, ukwakheka kwamashalofu aphakeme kakhulu, i-Roadway Stacking Cranes, indawo yokugcina impahla kanye nemishini yokuthutha imi kanje:

▷ ishalofu eliphezulu

Amashalofu aphakeme ayizindawo ezidingekayo ezindlini zokugcina izimpahla ezinezinhlangothi ezintathu ezizenzakalelayo. Ukusebenzisa amashalofu aphakeme kakhulu ukugcina izimpahla kungasebenzisa ngokugcwele indawo yokugcina impahla futhi kuthuthukise ukusetshenziswa kwendawo. Ngesikhathi esifanayo, amashalofu efomethi yezimpahla zeyunithi, amashalofu adonsela phansi namashalofu ajikelezayo asetshenziswa ngokujwayelekile. Imigqa emibili ngayinye yamashalofu aphakeme izokwakha iqembu, futhi umzila ubekwe phakathi kwamaqembu amabili amashalofu, ukuze umugqa wokupakisha umshini we-crane kanye nemishini ye-forklift kanye nezinsiza zisebenze ngokujwayelekile, kanye nomugqa ngamunye wamashalofu. ihlukaniswe yaba amakholomu amaningana kanye nemigqa evundlile ukuze yakhe ishalofu noma indawo yokugcina, esetshenziselwa kakhulu ukugcina ama-pallets noma iziqukathi.

▷ i-crane yokupakisha yomgwaqo

I-crane yokupakisha yomgwaqo ingashiwo ukuthi iyithuluzi elibalulekile endaweni yokugcina impahla enezinhlangothi ezintathu, eyaziwa nangokuthi umshini wokupakisha umgwaqo. Ukusebenza kwayo kufanele kube ukuma okunembile kanye nokuqashelwa kwekheli, ngaphandle kwalokho kuzothatha izimpahla ezingalungile, kulimaze izimpahla namashalofu, futhi kulimaze kabi umshini wokupakisha ngokwawo. Ukulawula indawo yesitaki kusebenzisa indlela yokuqaphela ikheli ngokuphelele, futhi isitholi sebanga le-laser sisetshenziselwa ukunquma indawo yamanje yesitaki ngokulinganisa ibanga ukusuka kusitaki ukuya endaweni eyisisekelo nokuqhathanisa idatha egcinwe ku-PLC kusengaphambili. Kuyizindleko eziphakeme, kodwa futhi nokuthembeka okuphezulu. Ikakhulukazi yakhiwe uhlaka, indlela yokusebenza, indlela yokuphakamisa, indlela ye-telescopic yemfoloko kanye nemishini yokulawula kagesi. Ngokuyinhloko isetshenziselwa ukusebenza nokusebenza emgwaqeni wamashalofu aphakeme kakhulu, igcine izimpahla emnyango womgwaqo ungene kugridi yezimpahla, noma ukhiphe izimpahla kugridi yezimpahla bese uzihambisa ekungeneni komgwaqo. Ukwengeza, isitaki somgwaqo singaphinde sihambe sivundlile eduze kwethrekhi phakathi kwamashalofu, futhi inkundla yokulayisha ingaphinde yehle ibheke phezulu ibheke phansi eduze kosekelo lwesitaki. Ngesikhathi esifanayo, imfoloko yesikhulumi sokulayisha ingaphinde ihambe iye kwesokunxele nakwesokudla sepulatifomu ngosizo lwemishini ye-telescopic, ukuze ibone ukunyakaza okuthathu kwempahla egciniwe negciniwe. Ngaphezu kwalokho, umthwalo olinganiselwe we-stacker yomgwaqo ngokuvamile ungamakhilogremu amaningi ukuya kumathani amaningana, futhi amabhizinisi amaningi asebenzisa u-0.5T ngaphezulu; Ijubane layo lokuhamba livamise ukuba ngu-4~120m/min, kanti ijubane lokuliphakamisa livamise ukuba ngu-3~30m/min.

▷ ukugcinwa kwempahla kanye nemishini yokuthutha

Ikakhulukazi kunezindlela ezimbili zokungena nokuphuma emishinini yokuthutha neyokuphatha eshede: engenamandla futhi inikwe amandla. Phakathi kwazo, imishini yokuthutha neyokuphatha engenamandla engenamandla engaphakathi nangaphandle kwe-warehouse nayo ihlukaniswe yaba uhlobo olukhulunywayo kanye nohlobo lwe-roller; Imishini yokuthutha kanye neyokuphatha yamandla angenayo naphumayo ihlukaniswe yaba iketango lokuthutha, ibhande elihambisa ibhande, isidlulisi esikhulumayo, njll. Izinto zokusebenza nezinsiza zokuthutha nokuphatha ngaphakathi nangaphandle kwendawo yokugcina impahla kuhlanganisa nezimoto eziziqondisayo, amaphalethi, ama-forklift, ukulayisha kanye nokuthulula. amarobhothi, njengeziqukathi noma imishini ye-pallet kanye nezinsiza. Ngokuvamile, izindawo zokugcina izimpahla ezinezinhlangothi ezintathu ezizenzakalelayo zivame ukusebenzisa iziqukathi noma amaphalethi njengabathwali. Kuyadingeka ukwazi ukuthi iziqukathi zingasetshenziswa ukubeka zonke izinhlobo zezimpahla ezinobunjwa obungajwayelekile kanye nezimpahla ezihlakazekile, ezinokwethenjelwa, eziphephile futhi okungelula ukuzihlakaza; Izindleko zokusebenzisa ama-pallets ziphansi, kodwa kuphela izimpahla ezinesimo esivamile noma ukupakishwa kwangaphandle kungabekwa, futhi ukuphakama kokupakisha kuma-pallets angeke kube kukhulu kakhulu. Ngaphezu kwalokho, ama-pallets anezidingo eziphezulu zesistimu yokutholwa kwe-stacker. Uma zingatholakali ngendlela efanele, izimpahla zingashayisana. Esinye isibonelo impahla kanye nezinsiza ngaphakathi nangaphandle kwesiteshi sebhafa yesitoreji. Isiteshi se-buffer ngokuyinhloko esokuxhumanisa isigqi sokukhiqiza futhi siqinisekise ukunikezwa okufika ngesikhathi nokunemba kwezinto. Ingadlala indima yokulawula uma kwenzeka kungasebenzi impahla yokukhiqiza, izinguquko zenqubo yokucubungula, ukuminyana kwezokuthutha, njll. Ukucutshungulwa kolwazi lwesiteshi sesiphakeli sokufinyelela kuhlobene eduze nendawo yokukhiqiza, okuhlanganisa isiteshi sebhafa somugqa oqinile, ukucubungula nokukhiqiza isiteshi sesiphakeli. kanye nendawo yokugcina impahla ye-buffer.

3) Izinsiza zikagesi neze-elekthronikhi

Izinsiza zikagesi neze-elekthronikhi endaweni yokugcina impahla enezinhlangothi ezintathu ezizenzakalelayo ikakhulukazi zifaka amathuluzi okubona, izisetshenziswa zokulawula, izisetshenziswa zokuqaphela ulwazi, okokusebenza kokubonisa isikrini esikhulu, okokusebenza kokuqapha izithombe, okokusebenza kokuxhumana, okokuphatha amakhompyutha, njll.

2. Uhlelo lokuphathwa kolwazi lwe-automated three-dimensional arehouse

Uhlelo lokuphathwa kolwazi lwendlu yokugcina impahla enezinhlangothi ezintathu ezizenzakalelayo luhlanganisa ukugcinwa kwesistimu, ukuphathwa kwesidingo, ukuphathwa kwe-oda, ukuphathwa kwesitoreji, ukuphathwa kwezimpahla okungafanelekile, ukuphathwa kwempahla nezinye izinhlelo ezingaphansi, kanje:

▷ ukugcinwa kwesistimu

Ukugcinwa kwesistimu kubhekisela ekuqalisweni kwalo lonke uhlelo, oluvame ukusetshenziselwa ukusetha amakhodi ahlukahlukene nezindlela zokucubungula, ikakhulukazi okuhlanganisa imodi yokuhlanganisa, imodi yokugcina impahla, imodi yeqoqo kanye nosuku, isizindalwazi kanye nokuqalwa kwekhodi yendawo.

▷ isistimu engaphansi yokulawulwa kwesidingo

Isistimu engaphansi yokulawulwa kwesidingo inquma kakhulu inani elidingekayo kanye nesikhathi sezinto zokwakha ngokuya ngohlelo lokukhiqiza, i-inventory, uhlu lwezimpahla, idethi, isimo sokuthengisa nolunye ulwazi.

▷ uhlelo olungaphansi lokuphathwa kwe-oda

Isistimu engaphansi yokuphatha ama-oda isetshenziswa kakhulu ukwenza ama-oda, ukufaka izinkontileka, ukuphatha amashejuli okuthenga, ukubala izinkontileka, nokuhlinzeka abaphathi ngezingobo zomlando eziyisisekelo ezifana nesithunzi, amandla okuhlinzeka nolwazi lobuchwepheshe bokukhiqiza lwabahlinzeki.

▷ isistimu engaphansi yokuphatha isitoreji

Isistimu engaphansi yokuphatha isitoreji ihlinzeka ngokuyinhloko ngemisebenzi ehlukahlukene ekulawuleni isitoreji, okuhlanganisa ukuphathwa kwendawo yesitoreji, ukuphathwa kwendawo yokugcina impahla, ukuphatha okuphumayo, ukuphathwa kwempahla nezinye izinhlelo ezingaphansi.

▷ isistimu engaphansi yokuphathwa kwezimpahla engavumelani

Isistimu engaphansi yokuphathwa kwezimpahla ezingavumelani ngokuyinhloko ibhekisela ekuphathweni kwezimpahla ezihlukahlukene ezingavumelani ngemva kokuba izingxenye zifike efektri noma izimpahla zifika enkampanini. Ngokuvumelana nezimpahla ezingavumelani nezibuyiswe kusukela ekwamukelweni kwendawo yokugcina izimpahla, ukukhiqizwa nokudayiswa, ifomu lesimangalo kanye nefomu lesinxephezelo liyakhiqizwa, bese izimpahla ezingavumelani nazo zidonswa ohlwini lwamagama.

▷ isistimu engaphansi yokuphathwa kwempahla

Isistimu engaphansi yokuphathwa kwempahla isetshenziswa kakhulu ukuqedela izibalo zokusungula, ukuhlaziywa kwesimo se-inventory, ukuphathwa kwezigaba ze-ABC, njll.

3, Ukuphathwa kokusebenza kwe-warehouse ezenzakalelayo

Ukuphathwa kokusebenza kwendlu yokugcina impahla enezinhlangothi ezintathu okuzenzakalelayo kunomthwalo wemfanelo ngokuyinhloko wokuhlela imisebenzi engenayo nephumayo, kanye nokuqedela umsebenzi wokuthutha izinto phakathi komugqa wokukhiqiza kanye nendawo yokugcina impahla eyiflethi (noma ezinye izinhlelo). I-warehouse in kanye ne-warehouse out yizinto eziyinhloko zokusebenza kwe-warehouse enezinhlangothi ezintathu. Uma sithatha amabhizinisi akhiqizayo njengesibonelo, izixhumanisi zokusebenza eziyisisekelo yilezi: izingxenye zeshede out, izingxenye zeshedehouse, impahla eqediwe ikhishiwe, indawo yokugcina impahla eqediwe, ngale ndlela elandelayo:

▷ izingxenye zokulethwa

Ukuze kuhlangatshezwane nezidingo zesikhathi sangempela zokucutshungulwa komugqa wokukhiqiza, izingxenye ezidingekayo zithunyelwa esiteshini esimisiwe sebhafa. Uhlelo lokusebenza lokulethwa luvela esiteshini se-buffer esicubungulayo noma esiteshini sebhafa sesiteshi. Uhlelo lokusebenza lokulethwa lubeka phambili izidingo zezinhlobonhlobo zezinto ezibonakalayo, imodeli, inani kanye nomkhawulo wesikhathi sokuhlinzeka. Ngemva kokuthola isicelo, indawo yokugcina impahla enezinhlangothi ezintathu izobuza indawo (imvamisa engaphezu kweyodwa) yezinto ezidingekayo ngokuhambisana nesimo samanje sempahla. Ngokuvumelana nesimiso semali yokuphathwa kwendawo, nquma inombolo yendawo yesitoko esiphumile, futhi ngokushesha wenze uhlu lwezingxenye zesitoko, njengenombolo yendawo yokuphuma kwesitoko, umkhawulo wesikhathi esincane sokunikezwa, inombolo yokuphuma kwesitoko, njll.

▷ ukugcinwa kwezingxenye

Lapho izingxenye zithunyelwa edeskini yokugcina impahla yendlu yezimpahla enezinhlangothi ezintathu, isiboni sebhakhodi sifunda ukwaziswa, sibeke phambili isicelo sokulondoloza, siyithumele endaweni emisiwe, bese sakha uhlu lwemisebenzi yokugcina izingxenye.

▷ ukugcinwa kwemikhiqizo eqediwe

Lapho imikhiqizo eqediwe ecutshunguliwe ifika edeskini lokugcina impahla enezinhlangothi ezintathu, umfundi webhakhodi ufunda ulwazi lwemikhiqizo eqediwe (inombolo, ubuningi, njll.) futhi afake isicelo sokugcina. Ihlanganiswe nesimo samanje sendawo, indawo yokugcina impahla enezinhlangothi ezintathu izothola indawo efanelekile engenalutho yomkhiqizo oqediwe ngokwezimiso zokuphatha indawo, futhi yakhe uhlu lomsebenzi wokubuyisela inqolobane ngesikhathi esifanayo.

▷ ukulethwa kwezimpahla kuqedile

Lapho ucubungula isicelo senkinga, ungakhipha ngokucacisa indawo noma inani elidingekayo lenkinga. Ngesikhathi esifanayo, ungakwazi ukuphakamisa ukubaluleka komsebenzi ngokuya ngokuphuthuma komsebenzi. Ngemuva kokwenza uhlelo lokudiliva nokwazisa indawo yokugcina impahla eyi-stereoscopic ukuthi iluqalise, indawo yokugcina impahla izonquma isikhathi sokulethwa, inani, ikhwalithi, uhlobo, njll. yemikhiqizo eqediwe ngokohlelo lokulethwa ngaphandle kwemboni, futhi inqume inombolo yendawo ngayinye. umkhiqizo oqediwe ozolethwa.

I-automated warehouse enezinhlangothi ezintathu iwuhlelo oluzishintshayo oluyinkimbinkimbi, olwakhiwe amasistimu angaphansi amaningi. Ku-automated warehouse enezinhlangothi ezintathu, ukuze uqedele imisebenzi eshiwo, kufanele kwenziwe ukushintshisana okuningi kolwazi phakathi kwezinhlelo nemishini. Isibonelo, ukuxhumana phakathi komsingathi kanye nesistimu yokuqapha, isistimu yokuqapha kanye nesistimu yokulawula endaweni yokugcina impahla enezinhlangothi ezintathu, kanye nokuxhumana phakathi kwekhompyutha yokuphatha i-warehouse kanye nezinye izinhlelo zolwazi ngenethiwekhi yekhompyutha. Imithombo yezindaba yokudlulisa ulwazi ihlanganisa izintambo, ukukhanya kwe-infrared, imicu yokubona kanye namaza kagesi.

Isikhathi sokuthumela: Jul-28-2022