I-As/rs (i-automated storage and retrieval system) yakhiwe ngokuyinhloko amashalofu anezinhlangothi ezintathu eziphakeme, izitaki zomgwaqo, imishini yokubamba phansi nezinye izinto zokusebenza zehadiwe, kanye nokuphathwa kwekhompyutha kanye nesistimu yokuqapha. Ngenxa yezinga eliphezulu lokusebenzisa indawo, amandla anamandla angenayo naphumayo, kanye nokusetshenziswa kwamakhompiyutha ukulawula nokuphatha, okuhambisana nokuqaliswa kokuphathwa kwesimanjemanje, isiphenduke ubuchwepheshe bokugcina obubaluleke kakhulu bokuphathwa kwebhizinisi nokuphathwa kokukhiqiza, kunakwe kakhulu ngamabhizinisi. Ngakho-ke hlobo luni lohlelo oluhlakaniphile oluwuhlelo lwe-as/rs lwe-automated three-dimensional warehouse, futhi luwasiza kanjani amabhizinisi ukwenza ukuphatha nokusebenza? Manje vumela umenzi weshalofu lokugcina i-hegerls we-hagris akuhlaziyele lona!

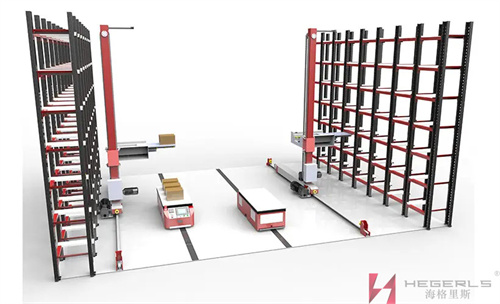

I-Intelligent as/rs iyimojuli ehlakaniphile eyengezwe ngesisekelo sendabuko njenge/rs. Enqubweni yokuhlela umsebenzi, ukwabiwa kwendawo kanye nokwenza kahle komugqa, ngokuya ngesimiso sokuhlela umsebenzi, isu lokwabiwa kwendawo, izinhloso zokwenza kahle ulayini nezingqinamba ezihambisanayo, nokusungula imodeli yedatha ehambisanayo, sebenzisa i-algorithm ehlakaniphile ukuxazulula, ukuthola isisombululo esifanele, futhi kuthuthukiswe ukusebenza kahle kwesistimu yokugcina impahla enezinhlangothi ezintathu ezizenzakalelayo.

Ukwakhiwa kwesistimu njenge/rs

I-automated-dimensional warehouse yakhiwe ikakhulukazi isistimu yokugcina impahla, njenge/rs i-warehousing system, as/rs management and monitoring system.

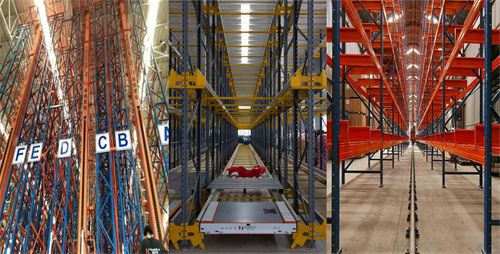

1) Isistimu yokugcina impahla

Yakhiwe ngendawo yezimpahla yeshalofu elinezinhlangothi ezintathu kanye nedivayisi yokuthwala impahla (ukupakishwa kwempahla, i-pallet, ibhokisi lenzuzo, njll.). Izinto ezisetshenziswayo zibekwe njalo futhi zigcinwe ngobunono kudivayisi ephethe izinto ezibonakalayo, futhi idivayisi ephethe impahla igcinwa kugridi yezimpahla, yakha uhlelo lokugcina oluqediwe.

2) Isistimu ye-As/rs yokugcina impahla

Uhlelo lwenza imisebenzi yokufinyelela kwezimpahla kanye nokungena nokuphuma endaweni yokugcina impahla. Ivamise ukwakhiwa ngesitaki somgwaqo, isidlulisi esingenayo nesiphumayo, imishini yokulayisha neyokuthulula, njll. Isitaki somgwaqo ukhreni osebenza emgwaqeni omncane wamashalofu aphakeme. Ingakwazi ukubona ukunyakaza okuthathu: ukuhamba eduze kwethrekhi, ukusuka okuqondile nokufika, kanye nokunwetshwa kwemfoloko nokufinyela. Isetshenziselwa ukugcina ngokuzenzakalelayo noma ukukhipha izimpahla kunoma iyiphi indawo yempahla ezinhlangothini zombili zamashalofu. Ngokwezimpawu zezimpahla, amaconveyor angaphakathi nangaphandle angakwazi ukusebenzisa amabhande ebhande, ama-roller conveyors, ama-chain drive conveyors, njll., athumela kakhulu izimpahla ezindaweni zokupakisha nokuthulula kanye nezimpahla ezingaphakathi nangaphandle kweshede. . Imishini yokulayisha nokulayisha yenza umsebenzi wokulayisha noma wokukhipha izimpahla ngaphakathi nangaphandle kwendawo yokugcina izinto. Ngokuvamile kwakhiwa ama-cranes, ama-cranes, ama-forklift neminye imishini.

3) Njengo/rs uhlelo lokuphatha nokuqapha

Yakhiwa ikhompuyutha yeklayenti, ikhompyutha yokulawula emaphakathi kanye nohlelo lokulawula ngogesi. I-as/rs management and monitoring system ayigcini nje kuphela ngokuphatha futhi ihlaziye imininingwane yempahla, isimo sokugcina kanye nelogi yokusebenza kwesherehouse ye-warehouse enezinhlangothi ezintathu, kodwa futhi iqapha isimo sokusebenza kwesikhathi sangempela sendawo yokugcina impahla enezinhlangothi ezintathu futhi ihlela okulungisekayo ngesikhathi sangempela. izinsiza ze-warehouse enezinhlangothi ezintathu.

I-Intelligent as/rs system structure and process

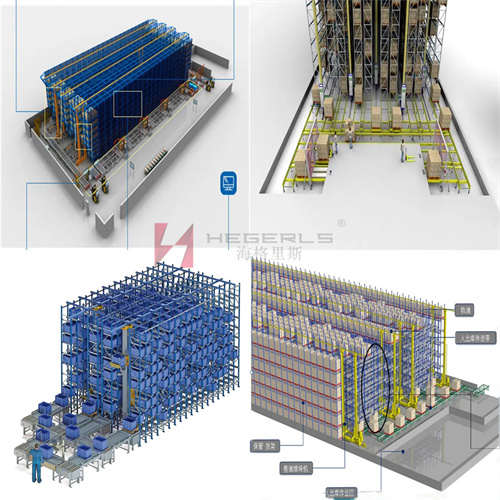

1) Isakhiwo sesistimu

I-automated-dimensional warehouse iwuhlelo oluphelele oluhlanganisa ukusetshenzelwa, ukulawula kanye neziyalo zekhompyutha. Izindlela zokufaka isicelo zokuphathwa kwempahla enezinhlangothi ezintathu ezizenzakalelayo kanye nohlelo lokuqapha zingahlukaniswa zibe phakathi, zihlukaniswe futhi zisatshalaliswe. Njengamanje, amaphrojekthi amaningi emhlabeni asebenzisa amasistimu asabalalisiwe.

I-Wmos (i-warehouse management kanye nesistimu yokusebenza) i-architecture ivame ukuhlukaniswa izingxenye ezine: ungqimba lwesicelo, isendlalelo sesevisi, isendlalelo sokulawula kanye nesendlalelo semishini. Kusukela ezingeni lokusebenza, isistimu yokugcina impahla enezinhlangothi ezintathu ezizenzakalelayo ingahlukaniswa ngamaleveli amathathu: izinga lokuphatha, izinga lokuqapha kanye nezinga lokukhishwa.

Ukuphatha: kuwuhlelo lokuphatha ikhompuyutha, olunomsebenzi wokusetha uhlelo, ukugcinwa kolwazi lwesistimu, ukugcinwa kolwazi lomkhiqizo, ibhizinisi lokugcinwa kwempahla, izibalo zemibuzo yokusungula, njll. Abaphathi yibona ababhekele kakhulu ukuhlela ukusebenza, ukusatshalaliswa kwempahla, ukwenziwa kahle komugqa, ukuphathwa kwamaphutha, njll. kwendawo yokugcina impahla enezinhlangothi ezintathu.

Isendlalelo sokuqapha: siyingxenye ebalulekile yesistimu ye-warehouse enezinhlangothi ezintathu ezizenzakalelayo. Ilawula okokusebenza ngokulandela imiyalelo evela kubaphathi futhi iqedele imisebenzi edluliswa ngabaphathi; Ngakolunye uhlangothi, ungqimba lokuqapha luqapha isimo sesitaki ngesikhathi sangempela ngendlela yokugqwayiza, futhi lubuyisela ulwazi lwamanje lwesitaki kubaphathi, lunikeze ireferensi konjiniyela ukuhlela imisebenzi.

Isendlalelo esiphezulu: sakhiwe ngesitaki esishumekwe ku-PLC. I-PLC kusitaki ithola imiyalelo evela kungqimba lokuqapha futhi yenza imisebenzi ehlukahlukene ngokwemiyalelo.

Eqinisweni, kungabonakala futhi ukuthi abaphathi bawumgogodla wobuhlakani njenge/rs, futhi ukugcwaliseka kwayo okukhaliphile kubonakala ikakhulukazi kumamojula amane abalulekile: imojula yesabelo esihlakaniphile semisebenzi yomsebenzi, imojula yokucubungula ehlakaniphile yokusabalalisa impahla, imojula yokwenza kahle kakhulu ulayini / indlela yokusebenza, kanye nemojuli yokucubungula iphutha. Imojula ngayinye idlala indima ehlukile ezinhlotsheni ezahlukene zezinqubo zomsebenzi.

▷ imojuli yesabelo esihlakaniphile semisebenzi yokusebenza: ngokwesimo sokugcinwa kwezinto okufanele zilethwe futhi zigcinwe endaweni ngayinye yokugcina, yabela ngokunengqondo imisebenzi yokudiliva nokugcinwa kwempahla, ukuze kulinganiswe umthwalo womsebenzi weyunithi ngayinye yokugcina futhi kuncishiswe isikhathi sokulinda imisebenzi yokusebenza.

▷ Imojula yokucubungula okuhlakaniphile yokusabalalisa impahla: ngokuya ngemvamisa yezinto ezingaphakathi nangaphandle kweshede, izici zomzimba, isimo samanje sokwabiwa kwempahla, njll., yabela ngokunengqondo indawo yokugcina impahla ngaphakathi nangaphandle kweshede, ukuze kuthuthukiswe ukusebenza kahle kweyunithi yokugcina impahla ngaphakathi nangaphandle kweshede.

▷ ulayini womsebenzi / imojula yokwenza kahle okuhlakaniphile: lungiselela ukulandelana komugqa noma indlela yomsebenzi yesitaki ngokuya ngemingcele yokusebenza yesistimu yokugcina izinto, ukuze unciphise isikhathi sokusebenza sesitaki futhi uthuthukise ukusebenza kahle kwesitoreji.

▷ Imojula yokucubungula ngamabomu: Le mojula ikakhulukazi ikhuluma ngamaphutha okuhlela okunengqondo, kunokuba amaphutha emishini namaphutha okuxhumana. Bhekana nephutha lokucabanga ngesikhathi futhi ulandele umsuka wephutha.

Isakhiwo se-intelligent as/rs sakhiwe ngendlela yokuhlela ehlakaniphile njenge/rs kanye nendlela yokulawula yokusungula. Indlela ekhaliphile yokuhlela yendlu yokugcina impahla enezinhlangothi ezintathu kuqala inquma uhlelo lokuhlela oluhlakaniphile olusebenzayo ngokusebenzisa umgomo wenqubo ye-analytic hierarchy ngokuya ngesilinganiso, ukwakheka, indawo yokugcina impahla kanye ne-warehouse out yesistimu, isu lokwabiwa komsebenzi, isu lokusabalalisa impahla kanye nenqubo yokucubungula kanye nolunye ulwazi lwe-warehouse ethile. Okwesibili, ngokohlelo lokuhlela oluhlakaniphile, isinyathelo sokuqala ukwaba imisebenzi kusukela ezingeni lilonke le-warehouse, nokwaba inqolobane bese ubeka imisebenzi ezindaweni ezithile zokugcina; Isinyathelo sesibili ukwaba izindawo zokugcina amayunithi athile okugcina; Isinyathelo sesithathu siwukuthuthukisa ulayini weqoqo lomsebenzi weyunithi ngayinye yokugcina ngokuya ngomphumela wokwabiwa kwendawo esinyathelweni sangaphambilini. Indlela yokuhlela ehlakaniphile iyindlela yokuhlela esabalalisiwe, kusukela ekwabiweni komsebenzi womhlaba wonke kuya ekwabiweni kwendawo kanye nokwenza kahle komugqa wamayunithi athile esitoreji.

2) Inqubo eyinhloko yohlelo oluhlakaniphile njenge/rs

▷ inqubo yokusebenza kwangaphakathi nokuphumayo: enqubweni yokusebenza yangaphakathi nangaphandle, ngokuya ngemininingwane yezinto okufanele zigcinwe zirekhodwe etafuleni lomhlangano wediski kanye nemininingwane yezinto ezizogcinwa ngohlelo lokulethwa, hlaziya ukugcinwa izinto ezihambisanayo endaweni yokugcina impahla enezinhlangothi ezintathu kuyunithi ngayinye yokugcina, futhi yabela imisebenzi kuyunithi ngayinye yokugcina. Ngemuva kokuthi iyunithi ngayinye yokugcina ithole imisebenzi ehambisanayo yokusebenza kwangaphakathi nangaphandle, ngokuya ngokusatshalaliswa kwezinto ezibonakalayo kweyunithi yokugcina, imojula yokucubungula okuhlakaniphile yokusabalalisa impahla inika indawo efanelekile emsebenzini ngamunye wokusebenza. Imojula yomugqa womsebenzi / indlela yokwenza okuhlakaniphile inika ukubaluleka kokuqala emisebenzini yenqwaba elinde ukwenziwa endaweni yokugcina. Imojula yokwenza kahle ulayini ingathuthukisa ulayini wenqwaba yomsebenzi ngokwezinjongo zokuthuthukisa ukuthuthukisa ukusebenza kahle kwesitoreji.

▷ inqubo yokubala: lokho okubizwa ngokuthi ukubala kubhekisela ekubaleni ukuze kutholwe inani langempela, izinga lekhwalithi kanye nesimo sokugcinwa kwezinto ezikhona noma impahla esitolo. Kuyinqubo yokulawula impendulo yokuphathwa kwezinto ezibonakalayo. Imodi yokusebenza yokubala ihlanganisa ukubala komhlaba wonke nokubala okungahleliwe. I-inventory yomhlaba wonke inezici zesikali esikhulu sokusungula, umjikelezo omude we-inventory, ukusetshenziswa kwezinsiza ku-inventory eyodwa, nomthelela ekukhiqizeni. I-inventory engahleliwe inezici zesikali esincane sokusungula, umjikelezo omfushane we-inventory, ukusetshenziswa okuncane kwensiza kanye nomthelela omncane ku-inventory eyodwa. Uma kubhekwa izici zohlu lwamagama olungahleliwe, uhlu lwamagama olungahleliwe lungabalwa izikhathi eziningi ngokuya ngosayizi we-inventory, ukuze kuthuthukiswe izinga lokusebenzisa elisebenzayo le-warehouse kanye nokuvumelana kwedatha yokulondoloza. Lapho umbiko onemininingwane yezinto ezisesitokweni ubalwa ekupheleni konyaka, kudingeka uhlu lwamazwe ngamazwe lwendawo yokugcina impahla. Inqubo yokubala ibandakanya umnyango wokuhlinzeka ngezinto ezibonakalayo, umnyango wokukhiqiza, umnyango wokuphatha indawo yokugcina impahla, umnyango wokuthengisa neminye iminyango eminingi, ukuze ithuthukise ukusebenza kahle kokubala, yonge isikhathi sokubala futhi yehlise umthelela ekukhiqizeni.

▷ Inqubo yokusebenza yokudluliswa kwesitoko: okugxilwe kukho kokudluliswa kwesitoko ukuhlunga izindawo ezidinga ukudluliselwa. Imojula yokucubungula ukusatshalaliswa kwezinto ezihlakaniphile igcina uhlobo olufanayo lwezinto zokwakha ngendlela emaphakathi ngokuya ngezidingo zokuhlangana okuhlobene kwezinto, futhi ikhetha indawo yokugcina impahla edinga ukuhanjiswa. Ngemuva kokunquma indawo yokugcina, ukulandelana kokusebenza kwendawo yokugcina kucaciswa ngokusebenzisa imodyuli yokwenza indlela yokusebenza ukuze kwakhiwe uchungechunge oluphelele lokugcina, ukunciphisa isikhathi sokungalayishwa kwe-stacker nokuthuthukisa ukusebenza kahle kokusebenza.

I-automated warehouse iyisistimu eyinkimbinkimbi, eguquguqukayo, yezinto eziningi kanye nezinjongo eziningi. Ukuphathwa okuhlakaniphile kwe-as/rs kuyinkinga eyinkimbinkimbi yokwenza uhlelo lube ngcono. Indlela yendabuko ayithathi nje isikhathi eside futhi ibiza kakhulu, kodwa futhi kunzima ukuthola isisombululo esifanele. Mayelana nalokhu, umkhiqizi weshalofu lokugcina i-Hergels uhlanganisa ithiyori yesimanje yokusebenza ngokukhaliphile ne-as/rs application, engathuthukisa ukusetshenziswa kwendawo kanye nezinga lokuphatha isitoreji, inciphise umfutho wabasebenzi, ithuthukise izinga lokuhlela izinto ezibonakalayo, isheshise inzuzo yezimali ezibekiwe, futhi inikeze isisekelo esisebenzayo. ngomyalo wokukhiqiza kanye nokwenza izinqumo kwamabhizinisi.

Isikhathi sokuthumela: Aug-03-2022