I-intelligent three-dimensional warehouse iyindawo ebalulekile ye-logistics ohlelweni lwesimanje lwezokuthutha. Isetshenziswa kabanzi esikhungweni se-logistics. I-warehouse enezinhlangothi ezintathu ehlakaniphile yakhiwe ngokuyinhloko ngamashalofu, ama-Roadway Stacking Cranes (izitaki), amapulatifomu omsebenzi wokungenela (okuphumayo), amasistimu okulawula ukuthunyelwa kanye nezinhlelo zokuphatha. Inqubo yokusebenza kwendawo yokugcina izinto enezinhlangothi ezintathu ehlakaniphile ngokuvamile igcina impahla, ukuphatha endaweni yokugcina impahla, ukugcinwa kwezimpahla, ukucosha kanye nokuphuma kwempahla eshede. Wonke umsebenzi wenziwa ngaphansi kokulawulwa kwesistimu yekhompyutha. Uhlelo lwekhompyutha ngokuvamile luwuhlelo lokuphatha nokulawula olunamazinga amathathu. Ikhompuyutha ephezulu ixhunywe ku-LAN, futhi ikhompuyutha ephansi ixhunywe kusilawuli se-PLC ukuze idlulise idatha ngezindlela ezingenantambo nezinezintambo. Ngasikhathi sinye, ukusungulwa kwendawo yokugcina izinto ehlakaniphile kudlala indima enkulu ekuthuthukiseni ukusebenza kahle kwezimpahla zamabhizinisi. Yebo, inkinga iphakama. Amabhizinisi amaningi noma abantu ngezinye izikhathi bangase bazibuze ukuthi uhlelo lokusebenza lwe-warehouse oluhlakaniphile lusetshenziswa kanjani ngendlela efanele, futhi yini umehluko phakathi kwalo nezindawo zokugcina izimpahla ezivamile? Imaphi amaphuzu abalulekile enqubweni ngayinye adinga ukunakwa kwethu? Landela izinyathelo zomkhiqizi wamashalofu e-hegerls, futhi nihlole imininingwane yohlelo lokusebenza lwe-warehouse ehlakaniphile ndawonye!

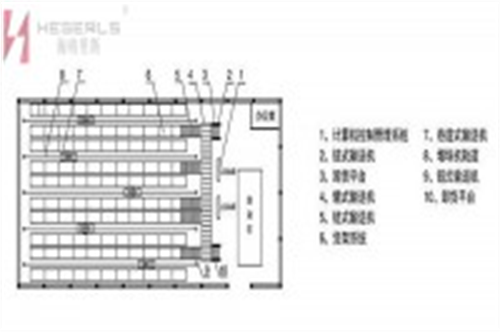

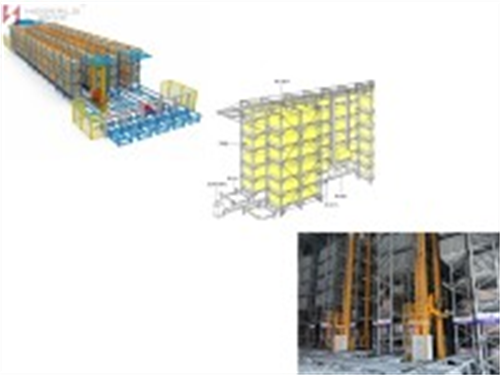

Ekuqaleni, sesishilo kakade ukuthi indikimba eyinhloko yendawo yokugcina impahla ehlakaniphile yakhiwe ngamashalofu, uhlobo lomgwaqo we-Stacking Cranes, i-warehouse entry (yokuphuma) ibhentshi lokusebenzela kanye nokuhamba okuzenzakalelayo ku-(phuma) kanye nohlelo lokulawula ukusebenza. Phakathi kwazo, ishalofu liyisakhiwo noma indikimba yesakhiwo yesakhiwo sensimbi noma isakhiwo sikakhonkolo esiqinisiwe, ishalofu liyindawo yokulayisha esezingeni elijwayelekile, kanti i-road stacking crane idlula emgwaqeni phakathi kwamashalofu ukuze iqedele umsebenzi wokugcina nokuthatha. ; Mayelana nokuphatha, uhlelo lwe-WCS lusetshenziselwa ukulawula.

Nawa amaphuzu abalulekile ohlelweni lokusebenza lwe-warehouse ehlakaniphile, kanje:

Inqubo yokugcinwa kwempahla: uhlelo lokuphatha luzophendula esicelweni sokugcinwa kwempahla, bese kuvela ibhokisi lengxoxo le-warehousing, elivumela umsebenzisi ukuthi agcwalise igama kanye nenani lempahla yokugcina impahla;

Umbuzo we-oda: bese isistimu ibuza inani le-oda. Uma inani le-oda likhulu kunenani le-inventory yezimpahla, isistimu izonikeza ukwaziswa kwe-alamu. Uma kungenjalo, isistimu yokusebenza izothumela umsebenzi wamarisidi e-Mo kukhompuyutha futhi iphrinte eshidini ledatha yamarisidi;

Ukuskena kwendawo yokugcina impahla: ikhompuyutha yokugcina impahla ilawula uhlelo lwebhakhodi ukuze luskene izimpahla;

Ukuhlunga nokuthutha: ngemva kokuskena, ikhompuyutha yokugcina impahla izophinde ihlulele ukuthi izimpahla eziskeniwe ziyahambisana yini nomsebenzi. Uma kunjalo, ukuhlelwa kwendawo yokugcina impahla kanye nokuthutha kuzokwenziwa. Uma kungenjalo, isignali ye-alamu izonikezwa.

Ukuhlanganiswa nokuhlanganiswa: ngaphambi kokuba izimpahla ezinosayizi omncane noma izingxenye zigcinwe, ukuhlanganiswa nokuhlanganiswa ngokuvamile kuyadingeka ukuze kuhlangatshezwane nezidingo zokulondoloza futhi kusetshenziswe ngokugcwele umthamo wendawo yokugcina. Izimpahla ezinosayizi omkhulu zingagcinwa ngqo noma zifakwe kuma-pallet ngokuya ngesimo.

(Umkhiqizi wamashalofu okugcinwa kwe-Hercules hegerls kufanele futhi achaze amaphuzu abalulekile emininingwane yokuhlanganisa nokuhlanganisa: Ngokuvamile, ukuhlanganiswa okungaguquki nokuhlanganiswa kuyamukelwa, okungukuthi, izimpahla eziningi noma izingxenye zohlobo olufanayo zifakwa kuphalethi eyodwa noma esitsheni; kwezinye izimo, ukuze kuqhutshekwe nokwandisa umthamo wokulondoloza, imodi yokuhlanganisa izingxenye ezixekethile ingamukelwa, okungukuthi, izinhlobo ezingahleliwe nenani ziqoqwa ezitsheni Kule modi, i-In database, ulwazi olufana nekhodi yeqoqo ikhodi yeqoqo, kanye nekhodi yeqoqwana yokufika yezimpahla nezingxenye kusethelwe ukuxhumanisa inani nohlobo lwezimpahla epuletini ngalinye nendawo yazo yokugcina, ukuze kube lula ipuleti elibuyela emuva nokuhlanganiswa ngesikhathi sokulethwa.)

Okokufaka kokuskena ibhakhodi: Ngokuvamile, ibhakhodi yezimpahla iqukethe izinhlobo ezine zolwazi, okungukuthi, inombolo ye-pallet, inombolo ye-athikili, inombolo yeqoqo kanye nenani. (Qaphela: ibhakhodi ifundwa yisithwebuli, ihunyushwe yi-decoder, bese idluliselwa kukhompuyutha ngesixhumi esibonakalayo sembobo ye-serial)

Inqubo yenkinga: lapho uhlelo lokuphatha luphendula esicelweni senkinga, ibhokisi lengxoxo yenkinga lizovela, livumele umsebenzisi ukuthi agcwalise igama nenani lezimpahla ezikhishiwe;

Umbuzo wenani le-inventory: uma isistimu yokusebenza ibuza ubuningi be-inventory, uma inani lokukhishwa likhulu kunenani le-inventory yempahla, i-alamu izonikezwa; uma kungenjalo, uhlelo luzothumela idokhumenti yomsebenzi wodaba kukhompuyutha ekhishiwe futhi liphrinte idokhumenti yodaba;

Umyalelo ophumayo: ikhompuyutha ephumayo ithumela umyalelo ophumayo emshinini wesitaki, othunyelwa usuka eshalofini futhi uthuthelwe endaweni yesikhulumi esiphumayo. Ikhompyutha ephumayo ilawula uhlelo lwebhakhodi ukuskena izimpahla;

Ukuhlunga nokupakisha kabusha: ngemva kokuskena, ikhompuyutha ye-warehouse izokwahlulela ukuthi izimpahla eziskeniwe ziyahambisana yini nomsebenzi. Uma zingaguquguquki, ukuhlunga nokupakishwa kabusha kwe-warehouse kuzokwenziwa. Uma kungenjalo, isignali ye-alamu izonikezwa.

Ngokusebenza kwe-ASRS, iphuzu elibalulekile okufanele lishiwo ngumkhiqizi weshelufu wesitoreji se-Hercules hegerls ukusebenza kwesitaki. Kukhona futhi amaphuzu ayisishiyagalombili okufanele abanikazi bamabhizinisi banake, kanje:

1) Iziqondiso zokusebenza: ngaphambi kokusebenzisa isitaki, u-opharetha kufanele afunde ngokucophelela imanuwali yokusebenza ye-ASRS yendlu yokugcina impahla enezinhlangothi ezintathu, noma ukusebenza kungenziwa kuphela ngemva kokuqondiswa okufanele;

I-2) I-Air compressor: ngaphambi kokuba i-stacker (ikhompyutha ephezulu) iqale, i-compressor yomoya kufanele ivulwe kuze kube yilapho ukucindezela kugcinwa, bese i-stacker ingasetshenziselwa ukugcinwa, ngaphandle kwalokho i-pallet kanye nomzimba womugqa uzolimazwa ngemfoloko;

3) Ukufinyelela ezimpahleni: ukufinyelela mathupha empahleni ye-ASRS endaweni yokugcina impahla enezinhlangothi ezintathu ngeke kuvunyelwe;

I-4) Imishini yokungeniswa: ngesikhathi sokusebenza kwangaphakathi nangaphandle, akuvunyelwe ukuba abaqeqeshwayo bahlanganise imishini yokufaka yomshini wokuhumusha ongenayo, ophumayo noma we-sorter jacking ngezandla zabo;

5) Uphawu lwesimo: empeleni, kunamamaki wesimo amathathu kusitaki, okungukuthi, isimo semanuwali, isimo esizenzakalelayo nesimo esizenzakalelayo. Isimo semanuwali kanye nesimo se-semi-automatic sisetshenziswa kuphela ngokuthuma noma izisebenzi zokunakekela. Uma zisetshenziswa ngaphandle kokugunyazwa, zizothwala imiphumela; Ngesikhathi sokuqeqeshwa, kuqinisekiswa ukuthi kusesimweni esizenzakalelayo;

I-6) Inkinobho yokumisa izimo eziphuthumayo: isitaki sisesimweni esizenzakalelayo, futhi ukusebenza kokufinyelela kwenziwa ngokuqondile yi-stacker. Esimeni esiphuthumayo noma ukwehluleka, ukucindezela inkinobho yokumisa izimo eziphuthumayo kusixhumi esibonakalayo sekhompyutha esiphezulu noma yonke inkinobho yokumisa umugqa kukhabhinethi yokulawula kagesi yolayini wokudlulisa nakho kunomphumela wokumisa izimo eziphuthumayo;

7) Ukuphepha kwabasebenzi: ngesikhathi sokusebenza kwangaphakathi nangaphandle, akuvunyelwe ukuthi abaqeqeshwayo basondele noma bangene endaweni yokugcina impahla enezinhlangothi ezintathu futhi balandelele umgwaqo, futhi bangasondeli kakhulu eduze kwendawo yokugcina impahla enezinhlangothi ezintathu, ugcine ibanga okungenani elingu-0.5m. ;

8) Ukulungiswa nokugcinwa: wonke ulayini udinga ukulungiswa njalo ezinyangeni eziyisithupha. Yiqiniso, abasebenzi abangewona umsebenzi abavunyelwe ukudiliza nokulungisa kabusha ngokuthanda kwabo.

Yebo, siphinde sasho ukuthi uyini umehluko phakathi kwe-ASRS nezindawo zokugcina izimpahla ezijwayelekile?

Eqinisweni, akunzima ukubona ukuthi umehluko omkhulu phakathi kwendlu yokugcina impahla enezinhlangothi ezintathu ehlakaniphile ye-ASRS kanye nendlu yokugcina impahla evamile ilele ekuzishintsheni nasekuhlakanipheni kwendawo yokugcina impahla ngaphakathi nangaphandle kwe-warehouse:

I-warehouse evamile isho ukuthi izimpahla zibekwa phansi noma emashalofini avamile (imvamisa engaphansi kwamamitha ayi-7) futhi zifakwa futhi ziphume mathupha endaweni yokugcina impahla ngeforklift; I-automated three-dimensional warehouse i-ASRS iwukuthi izimpahla zibekwe eshalofini eliphezulu (imvamisa engaphansi kwamamitha angu-22), futhi ngaphansi kokulawulwa kwesofthiwe, okokusebenza kokuphakamisa kungena ngokuzenzakalelayo futhi kuphume endlini yokugcina impahla.

Impela, amaphuzu abalulekile okuthi umtapo wolwazi ohlakaniphile onezinhlangothi ezintathu we-ASRS ungcono kunezindawo zokugcina izimpahla ezijwayelekile akulezi zici ezilandelayo:

Uxhumano olungenazihibe: lungaxhunywa nesistimu yokukhiqiza ezenzakalelayo ekhuphuka nomfula kanye nesistimu yokusabalalisa engezansi ukuze kuthuthukiswe ububanzi nokujula kwe-automation ye-enterprise supply chain.

I-Informatization: ubuchwepheshe bokuhlonza ulwazi kanye nesofthiwe esekelayo ibona ukuphathwa kokwaziswa ngaphakathi kwendawo yokugcina impahla, engabamba amandla e-inventory ngesikhathi sangempela futhi ibone ukuhlela ngokushesha.

Akunamuntu: ukuxhumeka okungenamthungo kwemishini yokuphatha ehlukahlukene kungabona ukusebenza okungenamuntu kwendlu yonke yokugcina impahla, ukuze kwehliswe izindleko zabasebenzi futhi kugwenywe ingozi efihliwe yokuphepha kwabasebenzi kanye nobungozi bokulimala kwempahla.

Isivinini esikhulu: ijubane lokulethwa komzila ngamunye lidlula i-50 Torr / h, ephakeme kakhulu kuneloli le-forklift, ukuze kuqinisekiswe isivinini sokulethwa kwempahla.

Okujulile: ukuphakama kwesitoreji kungafinyelela ngaphezu kwama-20m, indawo yomgwaqo nempahla icishe ibe ububanzi obufanayo, futhi imodi yokulondoloza esezingeni eliphezulu ithuthukisa kakhulu izinga lokusetshenziswa komhlaba.

Isikhathi sokuthumela: Jun-09-2022