Ngokuthuthuka okusheshayo kwemboni yezokuthutha yesimanje, indawo yokugcina impahla enezinhlangothi ezine yemoto isiphenduke enye yezindlela ezijwayelekile zezindawo zokugcina izimpahla ezinezinhlangothi ezintathu ezizenzakalelayo ngenxa yezinzuzo zayo ekusebenzeni kahle nokucinene kwesitoreji, izindleko zokusebenza, kanye nobuhlakani obuhlelekile. ukuphathwa ohlelweni lokugcinwa kwempahla.

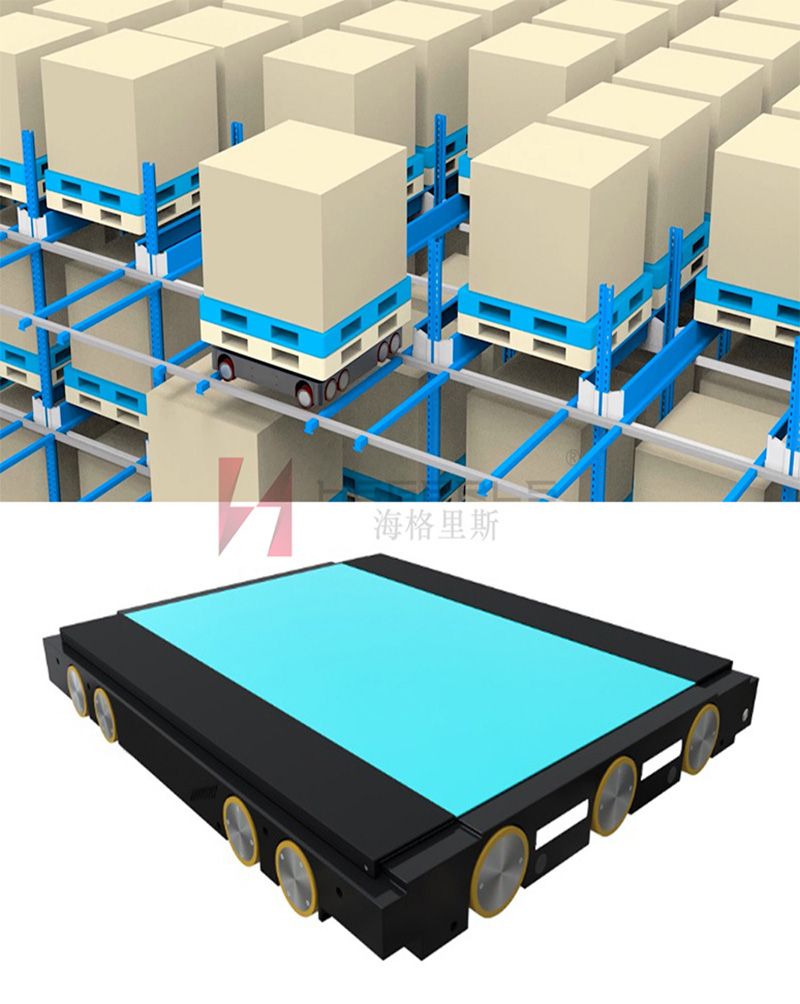

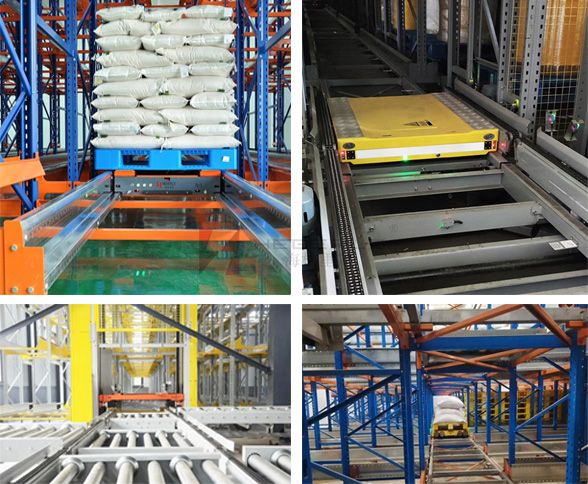

I-four way shuttle car three-dimensional warehouse iwuhlobo lwe-automated three-dimensional warehouse, ehlanganisa imoto yokuthutha enezinhlangothi ezine, amashalofu anezinhlangothi ezintathu, amakheshi, imigqa yethreyi yokuthutha, imishini yokuphakamisa nokudlulisa, kanye nohlelo lokulawula isofthiwe. . Ingxenye yeshalofu isetshenziselwa ukugcina izimpahla, i-shuttle yezindlela ezine isetshenziselwa ukuthutha impahla eshalofini, futhi uhlelo lokulawula isofthiwe lusetshenziselwa ukulawula ukusebenza kwe-shuttle yezindlela ezine kanye nezinye izinto zokusebenza ezizenzakalelayo, futhi ukurekhoda isimo sangempela. wezimpahla. I-four-way shuttle car warehouse eyi-three-dimensional iyisisombululo esivamile esizenzakalelayo se-auto-dimensional three-dimensional esingasetshenziswa kokungajwayelekile, okungajwayelekile, kwe-aspect ratio enkulu noma inqwaba encane ehlukahlukene, izindawo zokugcina izimpahla ezinkulu ezihlukahlukene. Ngokusebenzisa ukunyakaza okuqondile nokuvundlile kwemoto ye-shuttle yezindlela ezine nokusebenzisana nekheshi ukuze kusetshenziswe ungqimba olushintshayo, ukugcinwa okuzenzakalelayo kanye nokubuyiswa kwezimpahla kungafinyelelwa, okulungele ukugeleza okuphansi nokugcinwa kokuminyana okuphezulu kanye nokugeleza okuphezulu kanye isitoreji sokuminyana okuphezulu. Isistimu yokugcina impahla enezinhlangothi ezintathu iwuhlobo olusha lwesistimu yokugcina izinto ehlakaniphile ehlanganisa imisebenzi eminingi efana nokunqwabelanisa okuzenzakalelayo, ukuphatha okuzenzakalelayo, neziqondiso ezingenamuntu. Ngokuthuthuka okusheshayo kwezimboni ze-warehousing logistics kanye ne-e-commerce, isetshenziswe kabanzi.

Indawo yokugcina impahla enezinhlangothi ezintathu yezimoto ezihamba ngezindlela ezine iyinkimbinkimbi kakhulu ekuhlelweni kokulawula, ukuphathwa kwe-oda, ama-algorithms okuthuthukisa umzila, nezinye izici, okwenza ukuqaliswa kwephrojekthi kube nzima kakhulu. Ngakho-ke, kukhona abahlinzeki abambalwa uma kuqhathaniswa, futhi i-Hebei Woke Metal Products Co., Ltd. (umkhiqizo ongowakho: HEGERLS) ungomunye wabahlinzeki abambalwa.

Uma kuqhathaniswa nokugcinwa nokuthunyelwa kweshelufu lendlu yokugcina impahla, isixazululo se-shuttle yezindlela ezine siguqule uhlelo oluyisicaba “lwempahla kubantu” lwaba uhlelo lwe-3D “lempahla kubantu” enezingqimba eziningi, lwakha indawo yokugcina impahla enezinhlangothi ezintathu ezenzakalelayo enesitoreji esiphezulu nesiminyene. izikhala. Isixazululo se-HEGERLS se-shuttle three-dimensional arehouse solution sifanelekile ukugcinwa kwezinto ezicacisiwe zemoto njengama-pallets, imigqomo, namabhokisi ekhadibhodi, futhi ifaneleka ezinhlobonhlobo zezakhiwo eziyinkimbinkimbi zendawo kanye nezimo zemboni. Kuhlelo olufanayo lwesakhiwo sendawo, i-HEGERLS isistimu ye-shuttle ye-shuttle three-dimensional warehouse inezinga eliphakeme lokuzishintsha kanye namandla okucubungula angenayo naphumayo anamandla uma kuqhathaniswa nezinhlelo zendabuko zokugcina impahla, ezinganciphisa kakhulu isikhathi sokucubungula umsebenzi.

Inqubo yokusebenza ye-HEGERLS yemoto enezinhlangothi ezine yeshuttle car warehouse enezinhlangothi ezintathu

I-1) Isitoreji: Ithreyi yokugcina ibekwe ngokuqondile echwebeni lokugcina nge-forklift, futhi ngemva kokucindezela inkinobho yokugcina, ulayini wokuthutha uhamba ngendlela yokugcina. Ngemva kokuhlola ukubukeka, hlola ukuthi izimpahla zibekwe ngendlela efanele yini. Uma zifanelekile, zizogcinwa futhi ziskenwe ngamabhakhodi; Uma ingafaneleki, izobuyiselwa endaweni yokugcina izimpahla futhi izimpahla zizohlelwa kabusha mathupha. Iskena sebhakhodi siskena ikhodi yephalethi. Ngemva kokuskena ngempumelelo, i-WCS (isistimu yokulawula) ibuyisela inani lebhakhodi ku-WMS. I-WMS (uhlelo lolwazi lokuphathwa kwekhompyutha) lunikeza indawo yempahla ngokusekelwe enanini lebhakhodi futhi iyithumele ku-WCS (kuhlanganise nolwazi olufana nenani lezendlalelo, imigqa, amakholomu, nokujula kwendawo yomthwalo); I-WCS ithumela ulwazi lwendawo yempahla etholiwe ku-PLC; I-PLC ilawula ukusebenza kolayini wokuthutha ngokuthola ikheli lendawo ukuze ligcinwe; Ngesikhathi esifanayo lawula i-hoist ukuze uthuthe izimpahla kusendlalelo yendawo okuyiwa kuyo. Uma isikena sihluleka ukuskena ikhodi, i-WCS izohlinzeka ngempendulo ku-WMS ngomphumela wokuhluleka kokuskena, futhi ulayini wokudlulisa uzoyeka ukusebenza bese ulinda ukucutshungulwa mathupha; Uma inani lokuskena linqunywa i-WMS njengelingavumelekile, ulayini wokudlulisa uzoyeka ukusebenza bese ulinda ukucutshungulwa mathupha; Ama-opharetha angasebenzisa amatheminali aphathwayo ukuze askene amakhodi futhi noma ashintshe imininingwane yebhakhodi ukuze asingathe izimo zokuskena ezingajwayelekile. Uma izimpahla zidinga ukubuyiselwa ukuze zicutshungulwe, cindezela "inkinobho yokubuyisela" endaweni yokugcina impahla, futhi izimpahla zizobuyiselwa endaweni yokugcina ukuze zicutshungulwe.

2) Yeka ukulinda ukuthi izimpahla zihambe ziye kulayini wokuthutha emnyango wekheshi; I-PLC iqinisekisa inani lezendlalelo zeshalofu izimpahla okudingeka zifinyelelwe ngokusekelwe ekhelini lendawo yokugcina, futhi ishayela ikheshi. Lapho ilifti ifika esitezi sokuqala, ulayini wokuthutha uthutha izimpahla kukheshi, futhi impahla idlule ekheshini ukuze ifike endaweni okuyiwa kuyo; Ngemva kokuba ikheshi lifike endaweni okuyiwa kuyo, izimpahla ziphuma ku-elevator kanye nolayini wokuthutha wekheshi bese zilinda iloli elihambayo ukuze lilande izimpahla esikhumulweni sezindiza.

3) I-WMS (I-Computer Management Information System) ithumela imisebenzi engenayo njalo, futhi i-WCS (Isistimu Yokulawula) ithola imisebenzi engenayo futhi iyikhiphele kunqola yezimpahla eziya kuyo; I-shuttle ithola imiyalelo yangaphakathi, ishayela ifike endaweni yokuthatha impahla ukuze ithathe izimpahla, futhi izithuthe iziyise endaweni yezimpahla eziya kuyo. I-WMS (I-Computer Management Information System) ikhipha umsebenzi owodwa ngesikhathi, futhi i-WCS (Isistimu Yokulawula) yenza imisebenzi engenayo nephumayo ngokusekelwe kuhlelo lwemisebenzi ekhishwe i-WMS (Uhlelo Lolwazi Lokuphathwa Kwekhompyutha). Ngaphambi kokuthi i-WMS (I-Computer Management Information System) ikhiphe imisebenzi engenayo, kuyadingeka ukunquma ukuthi umsebenzi ophumayo usuqediwe yini; Ngemva kokuphothulwa komsebenzi ophumayo, umsebenzi ongenayo ukhishwa ukuze kuvinjwe umnqamulajuqu obangelwa ukusebenza kwezinsiza zolayini wokuthutha.

4) Eziphumayo: I-WMS (Isistimu Yolwazi Lokuphathwa Kwekhompyutha) ikhipha imisebenzi ephumayo (okuhlanganisa ikheli lokuqala nekheli okuyiwa kuyo) iye ku-WCS (Isistimu Yokulawula). Ngemva kokuba i-WCS (Isistimu Yokulawula) ithola umsebenzi ophumayo, izimpahla eziphumayo zithuthwa ngemoto ye-shuttle ezingeni lamanje lezimpahla kumugqa wokuthutha we-elevator; Izimpahla ziyayeka ukulinda kulayini wokuthutha emnyango wekheshi, kuyilapho i-PLC ilawula ikheshi ukuze ifinyelele izinga lamanje lezimpahla; Ngemva kokuba i-elevator ifinyelele izinga lamanje lezimpahla, umugqa wokuthutha uhambisa izimpahla ku-elevator. Ikheshi ithwala izimpahla iziyise ezingeni lokuqala, kanti izimpahla ziphuma ekheshini. Ulayini we-conveyor uhambisa izimpahla endaweni yokuphuma. Susa mathupha ithreyi bese uqedela inqubo ephumayo.

5) Ukungena, ukuphuma, nokudlulisa (ukuphuma, ukungena ngaphakathi) izindawo zinikezwe uhlelo lwe-WMS, futhi uhlelo lokulawula indawo yokugcina impahla alusekeli ukwabiwa kwezindawo; Uma kunethreyi evimba imoto ye-shuttle ehlakaniphile phakathi nendlela yayo yokuhamba, i-WMS idinga ukukhipha umsebenzi wokudlulisa inqolobane bese ikhipha ithreyi yokuvimba ngaphambi kokukhipha imisebenzi elandelayo.

6) Uhlelo lokulawula oluzenzakalelayo (WCS) lwenza imisebenzi ngokulandelana kwesikhathi esisitholile, bese kuthi imisebenzi etholwe kuqala yenziwe kuqala.

7) I-WMS (I-Computer Management Information System) ikhipha imisebenzi njalo, futhi ngemva kokuyibeka eqhulwini ngaphakathi, i-WCS ikhipha umsebenzi owodwa isikhathi ngasinye.

I-8) Ukusebenza kahle kokusetshenziswa kwemishini ye-automation kuhlobene eduze ne-oda lapho izimpahla zigcinwa futhi zibekwe khona, kanye nendlela yokushiya indawo yokugcina impahla kanye nokujula komhubhe. Lezi zindlela zinquma ukusebenza kahle kwangempela kwemishini yokugcina ye-automation. Ukusebenza kahle kwemishini ezishintshayo kusekelwe ekusebenzeni kahle okutholwe ngaphansi kwesisekelo sokusebenza kulesi simo esingenhla.

I-9) Uma imoto ye-shuttle isendlalelo esithile ingasebenzi kahle, ngemva kokuqinisekisa ngesandla ulwazi lwephutha, imoto engalungile ingathuthelwa endaweni engathinti izindlela ezingenayo neziphumayo. Izimoto ezingenzi lutho kwezinye izendlalelo zingaphakanyiswa futhi zifakwe esikhundleni sesendlalelo semoto esinephutha ukuze zenze imisebenzi.

U-Hebei Woke, njengomkhiqizi owaziwayo onamalungelo obunikazi bemishini efanele, utshale imali enkulu ocwaningweni nasekuthuthukisweni nasekuthuthukiseni ubuchwepheshe bemishini ehlakaniphile ehlobene njalo ngonyaka. Imboni yayo ye-HEGERLS inemigqa yokukhiqiza ezenzakalelayo kanye nokuphatha okuhlakaniphile, futhi manje isihambe emhlabeni jikelele. Ithenjwe amakhasimende amaningi emazweni nasezifundeni ezifana ne-Europe, America, Middle East, Latin America, naseNingizimu-mpumalanga ye-Asia, futhi iye yaklama ngokuzimela futhi yakhiqiza izimoto ezihlakaniphile zokuthutha i-Multilayer shuttle cars, izimoto zomzali nengane, ezinendlela emine. izimoto ezithuthwayo, nezitaki zomhubhe seziphenduke izinhlobo zempahla ezenzakalelayo enezinhlangothi ezintathu ezinkampanini eziningi.

Isikhathi sokuthumela: May-15-2023