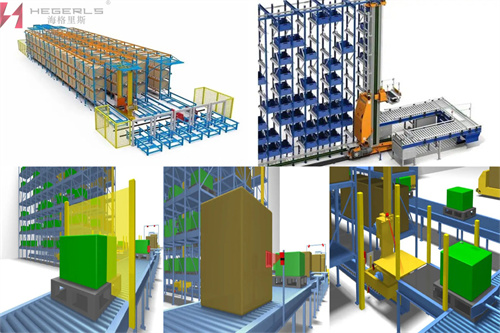

Izindawo eziyinhloko zokusebenza ze-automated warehouse enezinhlangothi ezintathu yindawo yokwamukela, indawo yokwamukela, indawo yokukhetha kanye nendawo yokulethwa. Ngemva kokuthola inothi lokudiliva kanye nezimpahla kumphakeli, isikhungo sempahla sizokwamukela izimpahla ezisanda kufakwa ngesithwebuli sebhakhodi endaweni yokwamukela. Ngemuva kokuqinisekisa ukuthi inothi lokulethwa liyahambisana nezimpahla, izimpahla zizophinde zicutshungulwe. Ingxenye yezimpahla ifakwa ngqo endaweni yokulethwa, okungeyezimpahla zohlobo; Enye ingxenye yezimpahla ingeyezimpahla zohlobo lwesitoreji, ezidinga ukugcinwa, okungukuthi, zingena endaweni yokukha. Ukukhetha kuqedwa ngokuzenzakalelayo isistimu yokuhlunga nokudlulisa okuzenzakalelayo kanye nesistimu yokuqondisa okuzenzakalelayo. Ngemuva kokuhlunga, izimpahla zingena endaweni yokugcina impahla enezinhlangothi ezintathu. Lapho izimpahla zidinga ukulethwa, ngokusho kwesibonisi kwinothi lokulethwa, izimpahla zizothunyelwa kulayini wokulayisha ohambisanayo ngokusebenzisa ukuhlunga okuzenzakalelayo kanye nemishini yokudlulisa. Ngemva kokuba izimpahla sezipakishiwe, zizolayishwa futhi zilethwe. Khona-ke indlela yokumisa ukusebenza kwe-automated warehouse enezinhlangothi ezintathu? Manje ake silandele i-hegerls warehouse ukuze sibone!

Ngokuvamile, izinto ezisetshenziswa ngokuvamile ezidingekayo ukuze zamukelwe, zigcinwe futhi ziphume zimi kanje:

Ithola ukusebenza

Izimpahla zizothuthelwa endaweni eqokiwe ngololiwe noma ngomgwaqo ngeziqukathi, futhi iziqukathi zizothululwa ngezinto zokusebenza zeziqukathi (okuhlanganisa nokhreyini weziqukathi, i-gantry crane yohlobo lwamasondo, i-rail type gantry crane, njll.). Ngokuvamile, izimpahla ezisesitsheni zifakwa ku-pallet kuqala, bese izimpahla zikhishwa kanye ne-pallet nge-forklift ukuze zihlolwe indawo yokugcina impahla.

Umsebenzi wokugcinwa kwempahla

Ngemva kokuba izimpahla sezihloliwe emnyango we-warehouse, zizobekwa phezu kwe-pallet ekhethiwe ngokuvumelana neziqondiso ezikhishwe uhlelo lokugcinwa kwekhompyutha. Ngokuvamile, i-forklift, isithwali sephalethi, isihambisi nesithwali esiqondiswayo esizenzakalelayo sisetshenziswa ndawonye ukuze kubekwe izimpahla kuphalethi. I-conveyor ingaba i-conveyor yebhande noma i-roller conveyor. Ngokuvamile, i-conveyor ne-AGV zilawulwa yikhompyutha.

Ngemuva kokuthi izimpahla zibekwe kuphalethi, isitaki somzila sizofaka izimpahla endaweni ebekiwe ngokwemiyalelo yesenzo, bese isitaki somzila sizohamba ngobude eceleni komzila. Ngesikhathi esifanayo, i-pallet izokhuphuka eduze kwekholomu ye-stacker. Ngesikhathi sokusebenza nokuphakanyiswa kwesitaki somzila, imininingwane yekheli izonikezwa ngokuqhubekayo kukhompuyutha. Ngesikhathi esifanayo, ikhompuyutha izothumela imiyalelo ehlukahlukene kusitaki somzila ukuze ulawule inqubo yokusebenza kwesitaki somzila, Ekugcineni, beka izimpahla endaweni ebekiwe eshalofini.

Lapha, ama-hegerls aphinde akhumbuze amabhizinisi amakhulu ukuthi amashalofu nezitaki ezisezingeni eliphezulu endaweni yokugcina impahla enezinhlangothi ezintathu kulula ukubona imikhiqizo esezingeni; Kodwa-ke, isistimu yokuthutha engenayo nephumayo izohlelwa ngokuqondile futhi iklanywe ngokuya ngesakhiwo sendlu yokugcina impahla, okuqukethwe kokungenayo nokuphumayo, inani leziteshi ezingenayo neziphumayo, kanye nezidingo zokuphambukisa kanye nokuhlanganisa. Ukuhlelwa nokuklanywa kwesistimu yokuthutha engenayo nephumayo kuyisihluthulelo sokusebenza kwe-automated warehouse enezinhlangothi ezintathu. Ukuhlelwa nokuklanywa kwesistimu yokuthutha engenayo naphumayo kuhlobene eduze nobukhulu obuphelele kanye nesakhiwo esingaphansi se-pallet, izindlela zokulayisha nokukhipha, ukulawula okuzenzakalelayo kanye nezindlela zokuhlonza zemishini yezokuthutha efanele.

Ukusebenza kwangaphandle

Ukulethwa kwezimpahla kanye nokusebenza kwendawo yokugcina impahla kulawulwa uhlelo olufanayo lokulawula, futhi inqubo yokusebenza iphambene.

Njengamanje, kube nezinhlobonhlobo zemishini ekhethekile yokusebenza, njengama-conveyors angenayo naphumayo, ayingxenye ebalulekile yezindawo zokugcina izimpahla ezinkulu neziyinkimbinkimbi. Zixhunywe nama-stackers neminye imishini ukuze kuzuzwe ukuthuthwa kwezimpahla ngesivinini esikhulu. Nakuba izinhlelo zokuthutha ezingenayo neziphumayo zomsebenzisi ngamunye zihlukile, zisakhiwa izinhlobo ezahlukene zokuthutha (i-chain conveyor, i-roller conveyor, i-chain roller table composite conveyor, i-chain roller table composite conveyor enomsebenzi wokudlulisa itafula) kanye namamojula awo ayisisekelo. .

Isikhathi sokuthumela: Aug-10-2022