Emabhizinisini amaningi, bajwayele amashalofu ezimoto zokuthutha. Ngokuvamile, izimoto ze-shuttle zingahamba ziye emuva naphambili ku-rack track ukuze zithwale izimpahla. Ezinye izikhombisi-ndlela ezimbili azikwazi ukuhamba ngenxa yemikhawulo. Uma kukhona imoto yokuthutha engakwazi ukuhamba kuzo zonke izinhlangothi ezine, ukusebenza kahle kwesitoreji kuzothuthukiswa izikhathi eziningana, okungukuthi, ishalofu lemoto ye-shuttle ezine. I-four-way shuttle truck rack iyindawo yokugcina izinto ehlakaniphile evele eminyakeni yamuva nje. Ngokusebenzisa iloli ye-shuttle yezindlela ezine ukuhambisa izimpahla kumathrekhi avundlile naqondile we-rack, iloli elilodwa le-shuttle lingaqedela umsebenzi wokuphatha impahla, lithuthukise kakhulu ukusebenza kahle komsebenzi. Ukusebenzisana nekheshi, uhlelo oluzenzakalelayo lokuphatha indawo yokugcina impahla (WMS) kanye nohlelo lokuthunyelwa kwempahla egciniwe (WCS), inhloso yokugcinwa ngokuzenzakalelayo kwendawo yokugcina impahla ingafezeka futhi kuthuthukiswe indlela yokuphatha indawo yokugcina impahla. Kuyisizukulwane esisha sesistimu yokubeka isitoreji esihlakaniphile.

Njengoba kusetshenziswa ishalofu le-shuttle yezindlela ezine, amabhizinisi amaningi angathola ukuthi isistimu ye-shuttle yezindlela ezine iyinkimbinkimbi kakhulu ekuhleleni ukulawula, ukuphathwa kwe-oda, i-algorithm yokwenza umzila, njll. Kunzima kakhulu ukusebenzisa iphrojekthi, ngakho-ke bambalwa abahlinzeki bempahla. Nokho, i-hegerls ingomunye wabahlinzeki abambalwa. I-Hegerls iyinkampani ekhiqiza insiza yokugcina impahla ehlanganisa i-R & D, ukuklama, ukukhiqiza nokuthengisa. Ingenye yabakhiqizi basekhaya abazenzakalelayo bokugcina kanye nemishini yezimpahla. Inohlelo oluphelele lokukhiqiza olunezinhlobonhlobo zemishini yokukhiqiza, ubuchwepheshe bokukhiqiza kanye nesevisi ephelele yangemva kokuthengisa, njengomshini wokuqhumisa othomathikhi ozenzakalelayo, isitembu sokulawula izinombolo, i-Hot Coil Slitting, iphrofayili evamile yokugoqa isigayo, i-x-shelf rolling. umshini, i-welding, i-electrostatic powder spraying automatic nokunye, Ibeke isisekelo esiqinile sokuphakela abasebenzisi kuzo zonke izigaba zokuphila futhi yanikeza isiqinisekiso! I-Hagerls igxile ku-R & D, ukukhiqizwa nokudayiswa kwama-racks okugcina, ama-cable racks, ama-attic racks, ama-shuttle racks, ama-racks asindayo, ngokusebenzisa ama-rack, ama-cantilever racks, ama-pallet ensimbi, izindawo zokugcina izimpahla ezizenzakalelayo ezinezinhlangothi ezintathu kanye nemishini yesiteshi engajwayelekile. Iphinde ibe nesofthiwe yohlelo lokuphatha isitoreji se-WMS ngokuzimela.

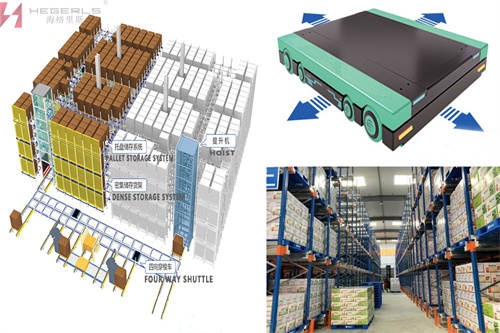

I-Hegerls four-way shuttle rack

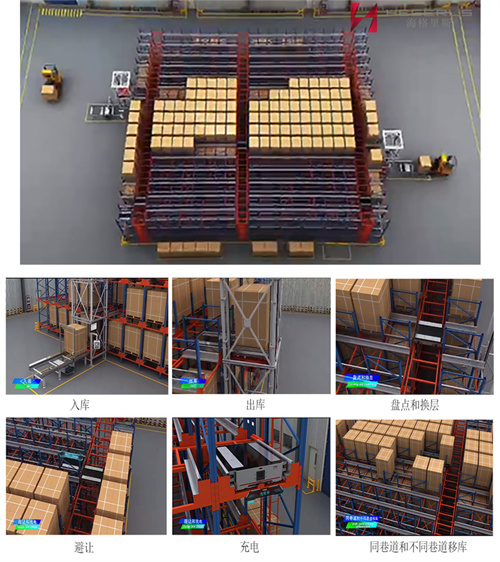

I-four-way shuttle rack iwuhlobo olukhaliphile lwe-high density storage rack. Kuyisitoreji esihlakaniphile esakhiwe ngamashalofu, izimoto zokuthutha kanye nama-forklift. Isebenzisa izimoto ze-shuttle ezine ukuze ibone ukusebenza kwethrekhi evundlile neqondile yamashalofu. Ukunyakaza okuvundlile nokugcinwa kwezimpahla kuqedwa kuphela ngemoto eyodwa ye-shuttle, esebenzisana nokudluliselwa kwe-elevator. Ngokubambisana kwe-automatic warehouse management system (WMS) kanye ne-warehouse dispatching system (WCS), uma isetshenziswa nekheshi, ingakwazi ukubona kahle ukusebenza kwethrekhi evundlile nevundlile, ukuze ibone umsebenzi wokukhetha nokuhlunga isitoreji.

Phakathi kwazo, i-four-way vehicle yaziwa nangokuthi i-four-way shuttle vehicle. Ingakwazi ukuhamba ngokuvundlile nangobude eduze nomthwalo wethrekhi onqunywe kusengaphambili ukuze ibone ukugcinwa kwezimpahla eshalofini. Izinto ezisetshenziswayo ziyakwazi ukubona ukulayishwa nokulayishwa okuzenzakalelayo, ukushintsha umzila ozenzakalelayo nokuguqulwa kwezingqimba, ukugibela okuzenzakalelayo, futhi kungathuthwa futhi kushayelwe phansi. Isizukulwane sakamuva sezinto zokuhamba ezihlakaniphile ezihlanganisa ukupakishwa okuzenzakalelayo, izinto zokuhamba ezizenzakalelayo, isiqondiso esingenamuntu kanye neminye imisebenzi. Imoto eyi-four-way shuttle iguquguquka kakhulu. Ingakwazi ukushintsha umzila wokusebenza ngokuthanda kwakho, futhi ilungise umthamo wesistimu ngokwandisa noma ukunciphisa inani lezimoto ezishuthwayo. Uma kudingekile, ingasabela esiqongweni sesistimu futhi ixazulule ibhodlela lemisebenzi yokungena nokuphuma ngokusungula imodi yokuthumela yemikhumbi yokusebenza.

Isistimu yemoto ye-shuttle yezindlela ezine eyakhiwe, ekhiqizwa futhi ekhiqizwa ama-hegerls iguquguquka kakhulu. Ngesikhathi esifanayo, umzila ungashintshwa ngokuthanda futhi ukusebenza kungamiswa kunoma yisiphi isikhundla ukuze kulungiswe umthamo wesistimu ngokwandisa noma ukunciphisa inani lezimoto ze-shuttle. Ngaphezu kwalokho, uhlelo lwemoto oluhamba ngezindlela ezine luyimodular futhi lusezingeni. Zonke izimoto ze-AGV zingashintshwa komunye nomunye, futhi noma iyiphi imoto ingaqhubeka nokwenza umsebenzi wemoto yenkinga. Isistimu yemoto ye-shuttle emine ingakwazi ukulungisa ngokuguquguqukayo umzila wokusebenza wemoto ye-shuttle futhi "ikhulule" umzila kanye ne-hoist, ukuze inkinga yebhodlela yemoto ye-shuttle ye-multi-layer ku-hoist ingaxazululwa. Ngaphezu kwalokho, okokusebenza kungalungiswa ngokuphelele ngokuya ngokugeleza kokusebenza, kuncishiswe imfucuza yomthamo wemishini. Ukusebenzisana phakathi kwe-shuttle car kanye ne-hoist nakho kuyavumelana nezimo futhi kuyavumelana nezimo. Kusistimu ye-shuttle ye-multi-layer yendabuko, uma i-elevator iphuka, wonke umsebenzi womhubhe uzothinteka, kanti uhlelo lwe-shuttle lwe-4 ngeke luthinteke. Phakathi naleso sikhathi, uma kuqhathaniswa nesistimu yeshelufu ye-multi-layer ye-shuttle yendabuko, i-shuttle yezindlela ezine izoba nezinzuzo eziningi ekuphepheni nasekuzinzeni. Ilungele ukugeleza okuphansi nokugcinwa kokuminyana okuphezulu kanye nokugeleza okuphezulu nokugcinwa nokuqoqwa okuphezulu, Ingakwazi futhi ukuhlangabezana kangcono nezidingo zamakhasimende.

Izici ezihlukile kanye nezinzuzo zamashalofu we-hegerls four-way shuttle vehicle

▷ Isitoreji seshelufu esiphakeme kakhulu: ngenxa yokuthi imoto yayo ye-shuttle yezindlela ezine ingahamba ngezindlela ezine, kukhulisa kakhulu ukuguquguquka kokuvumelana nesayithi. Lapho uhlangabezana nezingosi ezithile ezingajwayelekile, futhi ingasebenza ngokuguquguqukayo, ithuthukise izinga lokusetshenziswa kwendawo yonke futhi ilondoloze indawo yokugcina impahla, ecishe iphindwe izikhathi ezi-5-6 kunendawo yokugcina izinto evamile. Njengamanje, ukuphakama kwendawo yokugcina impahla enezinhlangothi ezintathu emhlabeni wonke sekufinyelele ku-15-20m, futhi umthamo wokugcina indawo ngayinye ungafinyelela ku-8t / m2. Kulula kakhulu, kuhlakaniphe kakhulu, kuyahlekisa futhi kuyabiza kakhulu ukufinyelela izimpahla.

▷ ukuhamba ngezindlela ezine: ingahamba noma iyiphi indlela elandela amathrekhi amade noma aguquguqukayo kumzila ophambanayo werack enezinhlangothi ezintathu, futhi ifinyelele noma iyiphi indawo yezimpahla esitolo ngemiyalo ethunyelwe uhlelo, ngaphandle kwesidingo sezinye. impahla yangaphandle. Akudingekile ukuthenga noma yiziphi ezinye izisetshenziswa zokuphatha kanye nemishini endaweni yokugcina impahla ezenzakalelayo, okunciphisa kakhulu izindleko zokuphatha.

▷ ukulinganisa okuzenzakalelayo: i-pallet ihlelwa ngokuzenzakalelayo yinzwa yokufuduka, futhi amasondo ezinhlangothini zombili ashayelwa ngesikhathi esifanayo ukuze kuqinisekiswe ukuthi i-shuttle yezindlela ezine ehlakaniphile ayiphambuki futhi igweme ingozi yokugingqika kwempahla.

▷ ukufinyelela okuzenzakalelayo: ukusebenza okusheshayo nesivinini sokucubungula, okukwazi ukudlulisa ngesikhathi sangempela nge-ERP, i-WMS nezinye izinhlelo ohlelweni lwezinto ezibonakalayo zebhizinisi.

▷ isilawuli esihlakaniphile: yonke imoto inezindlela ezimbili zokulawula: okuzenzakalelayo ngokuphelele kanye ne-semi-automatic. Kwimodi ezenzakalelayo, izimpahla zingangena futhi ziphume endaweni yokugcina impahla ngaphandle kokusebenza ngesandla, okulula ukubala nokubala, futhi ububanzi bokusungula bungalawulwa ngokunengqondo, okuthuthukisa kakhulu ukusebenza kahle kokufinyelela kwezimpahla kanye nokusetshenziswa kwendawo yokugcina impahla.

▷ ukuxhumana okungenamthungo: qaphela ukuxhumana okungenamthungo enqubweni yokukhiqiza, indawo yokugcina impahla kanye nokuhlunga.

▷ inkinga yephutha: lapho uhlangabezana nezithiyo noma ufika ekupheleni komsebenzi, i-shuttle yezindlela ezine ingenza impendulo ehambisanayo futhi ime ngokuzenzakalelayo ukuze ikhethe umzila wayo wokusebenza ongcono kakhulu ukuze uqhubeke nokusebenza.

▷ ukusebenza okuqinile kokumelana nokushayisana: sonke isakhiwo se-shuttle rack yezindlela ezine sisebenzisa idizayini entsha sha, eyenza ukusebenza kwayo kokumelana nokushayisana kuthuthukiswe kakhulu. Ngenxa yokuthi i-shuttle rack ye-shuttle yezindlela ezine iqhume ngokungenakugwenywa enqubweni evamile yokusebenza, uma ukusebenza kokulwa nokushayisana kwemishini kungaqinile, kuzoholela kalula ekulimazeni komzimba womshini futhi kuthinte ukusebenza kahle kwendawo yokugcina impahla. Kodwa-ke, i-shuttle rack yezindlela ezine inokusebenza okuhle kokulwa nokushayisana, Lokhu kungagwenywa ngokuphumelelayo.

▷ uhlelo lokugcina: umkhumbi wezimpahla ezihamba ngezindlela ezine wakhiwe izingxenye ezimbili: i-shuttle yezindlela ezine kanye nesistimu yokubeka isitoreji. Inozinzo nokuphepha okuphezulu. Uma i-hoist ohlelweni ihluleka, i-shuttle ye-four-way ingaqhubeka isebenza ngamanye ama-hoists noma imishini yokuxhuma, ukuze lonke uhlelo lwe-rack luqhubeke nokusebenza, futhi lonke uhlelo aluthinteki.

▷ inzuzo yokusebenza kahle: indawo yokusebenza kanye neshalofu elinezinhlangothi ezintathu kuxhumene ngokuqondile, futhi asikho isixhumanisi sokuphatha sesibili endaweni yokugcina izinto, okunciphisa izindleko zabasebenzi kanye nezinga lomonakalo wempahla.

▷ ukunwebeka okuqinile: indawo yokugijima ayinqunyelwe, futhi amashalofu anganwetshwa njengoba kudingeka ukuze ahlangabezane nezidingo zangempela zamakhasimende.

▷ ukwabelana kwensiza: sebenzisa inkundla yefu ukuze uhlaziye idatha yenqolobane nokwabelana ngensiza yedatha.

▷ FIFO: izimpahla zingena kuqala, ziphuma kuqala, futhi zingakhethwa ngokukhululekile;

▷ ukumelana nokuzamazama komhlaba: ukusebenza kokuphepha kokuzamazama komhlaba kuphezulu kakhulu kunokwedrayivu eshalofini;

▷ ukuncishiswa kwezindleko: ngokuya ngezindleko eziphelele zesistimu, uma kuqhathaniswa nesistimu yemoto eyisithuthuthu enezingqimba eziningi, izindleko zemoto yohlobo lwe-multi-layer shuttle ihlobene eduze nenani lemizila. Ngaphansi kwesimo sokwandisa umthamo wokuhleleka nokungakhulisi i-inventory, umzila ngamunye walezi zinhlelo uzokwandisa izindleko ezihambisanayo, kanti uhlelo lwezimoto ezine-shuttle ludinga kuphela ukwandisa inani lezimoto zokuthutha, futhi izindleko zizoba phansi. .

Isimo sesicelo seshelufu se-shuttle sezindlela ezine:

1) Intelligent factory workshop line side umtapo wolwazi;

2) Isitoreji esihlakaniphile esiqediwe ishede lomkhiqizo / inqolobane yomkhiqizo osuqediwe kancane / indawo yokugcina impahla eluhlaza;

3) Indawo yokugcina impahla yesikhungo sokusabalalisa impahla;

4) Inqolobane emnyama engenamuntu.

Eqinisweni, sekukonke, kusukela kumodi yamanje yezokuthutha kanye neyokugcina, kwezokwelapha, ukudla, izinto zikagesi zasendlini, izimoto, ugwayi nezinye izimboni, kunezindawo zokugcina izinto ezimise okukhethekile (umumo uhlukile, futhi indawo yokugcina impahla ngaphakathi nangaphandle ihlukile. ), izindawo zokugcina impahla eziphansi (indawo yokugcina impahla enesitezi esisodwa, indawo yokugcina impahla iphansi), iphansi lesitezi ngezindawo zokugcina izimpahla (indawo yokugcina impahla enesitezi esisodwa iphansi, futhi indawo yokugcina impahla ngaphakathi nangaphandle ingase ibe esitezi sokuqala), izindawo zokugcina impahla eziyisicaba (, ≤ 13.5m, phansi iphansi kakhulu, futhi ayifaneleki ukusebenzisa isitaki) Imoto ye-shuttle yendlela emine ingahlangabezana nezidingo zezindlela zokulondoloza ezihlukene njenge-warehouse emile (≥ 18m, ukusetshenziswa kwesitaki noma ukungaphumeleli okwanele).

Izinkinga zokuphepha ngesikhathi sokufakwa kweshalofu lemoto eyi-hegerls four-way shuttle

Isakhiwo sonke se-shuttle rack rack sikhulu kakhulu, futhi ingxenye ngayinye inezinkinga eziningi zokuxhuma, ezidinga ukusebenza kwesifaki. Uma ingeyinhle ngokwanele, kulula ukuvela. Uma i-perpendicularity yekholomu inganele, futhi i-engeli ayanele lapho ufaka ishalofu, ukuphatha kabi kuzoba nemiphumela emibi eshalofini jikelele. Ngaphezu kwalokho, izesekeli zokuphepha ezidingekayo eshalofini azifakiwe noma zibekwe ngendlela efanele, okuzokwenza buthaka ukuvikela. Le ndima ayihambisani nezokuphepha. Ukusebenza ngendlela engafanele kwezisebenzi ze-warehouse lapho usebenzisa amashalofu kungase kuholele ekuphepheni kwamashalofu. Isibonelo, ukubuyisela ngokweqile kwezimpahla kanye nokushayisana okunamandla kwamashalofu kungase kuholele ekugudluzweni noma ekuguqulweni kwamashalofu, ngaleyo ndlela kuthinte ukusetshenziswa okuphephile kwamashalofu.

Ngokuthuthuka komphakathi, imikhiqizo yeshalofu yokugcina ehlakaniphile ihlale ithuthuka, futhi imisebenzi nemisebenzi yayo iya ngokuya ibaluleke kakhulu, engakhuthaza ukuthuthukiswa okusheshayo kwemboni yezokuthutha. Ngakho-ke, akufanele sibukele phansi inqubekelaphambili yemboni yokugcina izinto ehlakaniphile kanye nenani layo emphakathini.

Isikhathi sokuthumela: Aug-15-2022