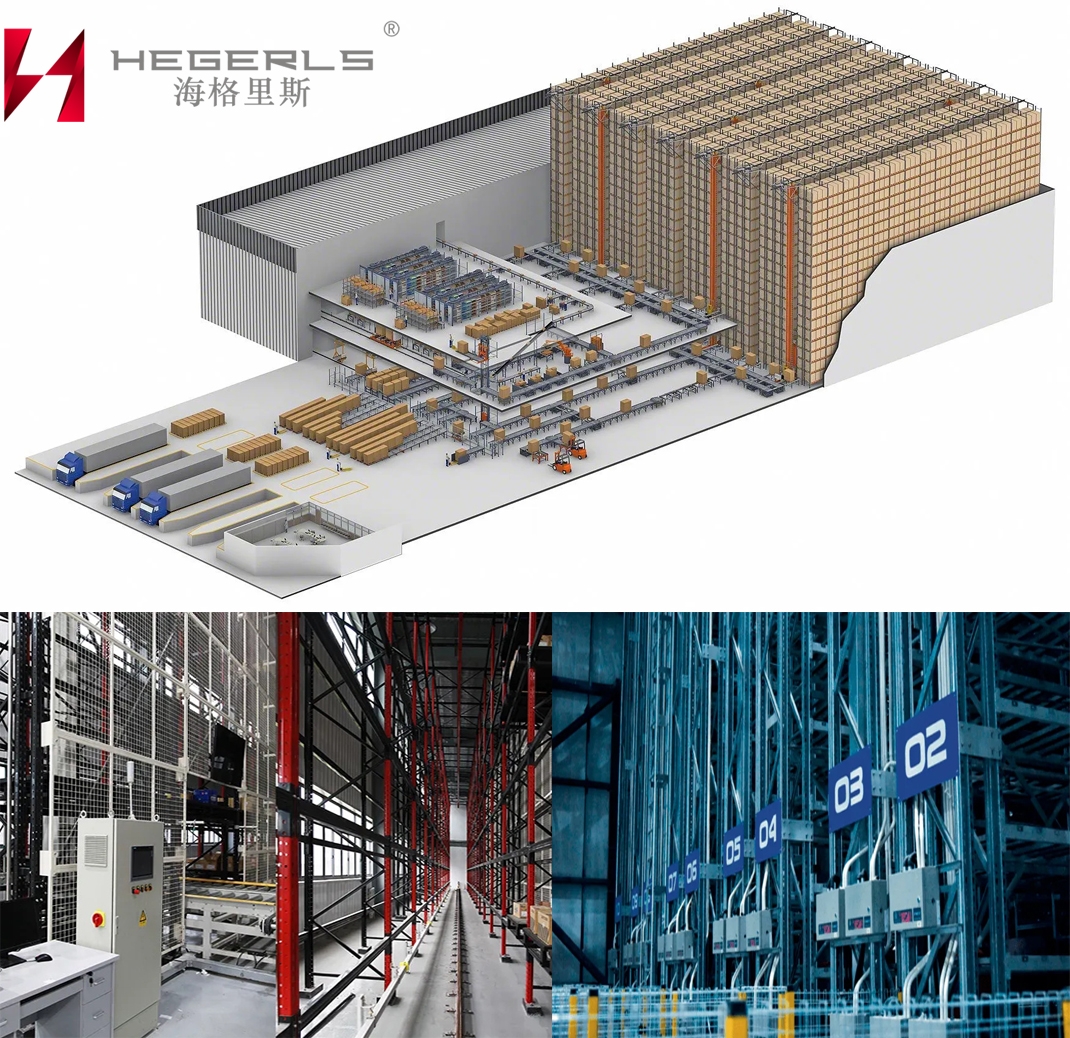

Ngokuthuthuka okuqhubekayo kobuchwepheshe obusha, eminyakeni yamuva nje, kuvele ulwazimagama olusha lomqondo, umtapo wezincwadi ozenzakalelayo onezinhlangothi ezintathu, ovele ohlelweni lwezokuthutha. I-automatic three-dimensional warehouse (AS-RS) iwuhlobo olusha lwendlu yokugcina impahla yesimanje esebenzisa amashalofu aphakeme kakhulu futhi ilandelela isitaki somgwaqo, futhi isebenzisana nezinhlobonhlobo zemishini yasendaweni ukuze ithole ukufinyelela okuzenzakalelayo nokuphathwa kwempahla. Ibona ukuhleleka kwezinga eliphezulu kwendawo yokugcina impahla enezinhlangothi ezintathu ngokusebenzisa okokugcina okuzenzakalelayo kanye nokulawula ikhompuyutha nobuchwepheshe bokuphatha, futhi yakhe isethi ephelele yesistimu yokuphatha indawo yokugcina impahla enezinhlangothi ezintathu ngokuhlanganisa izinhlobo ezahlukene zesofthiwe yokuphatha inqolobane, ukuqapha okuyingcaca kanye nokuhlela. isofthiwe, ukuhlonza ikhodi yebha kanye nohlelo lokulandela umkhondo, irobhothi elibambayo, i-AGV trolley, isistimu yokuhlunga impahla, uhlelo lokuhlonza isitaki, uhlelo lokulawula isitaki, umtshina wendawo yempahla, njll, Ngesikhathi esifanayo, izokwandisa umsebenzi womtapo wolwazi onezinhlangothi ezintathu futhi hlinzeka amabhizinisi ngesixazululo esiphelele se-logistics automation kusuka kwisitoreji, ukuthutha okuzenzakalelayo, ukukhiqizwa okuzenzakalelayo kuya ekusatshalalisweni komkhiqizo ophelile.

Kufanele wazi ukuthi ingxenye ngayinye yokwakheka kwesistimu ye-AS-RS idlala indima ethile nehlukile, ngale ndlela elandelayo:

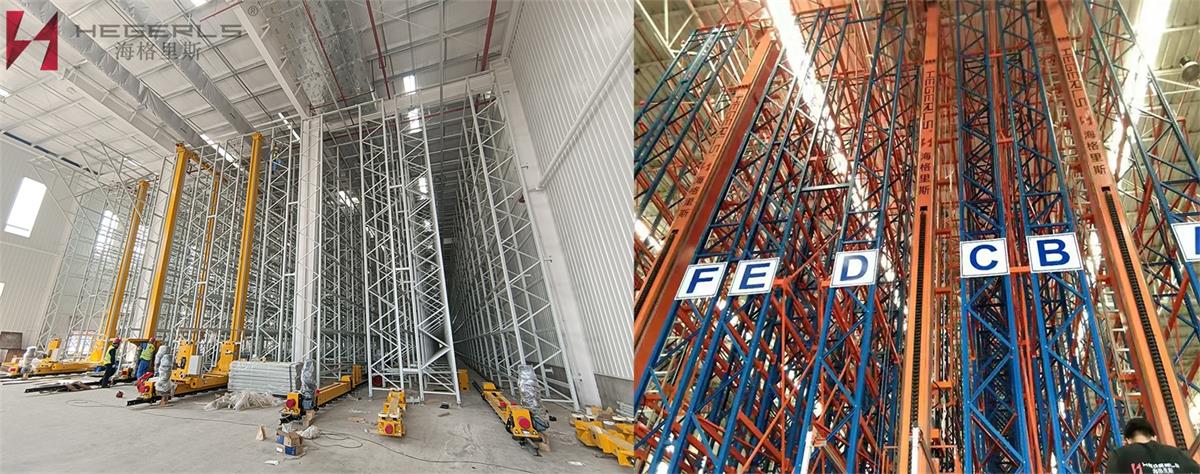

Amashalofu aphakeme kakhulu: amashalofu aphakeme kakhulu asetshenziselwa ukugcina izimpahla ezakhiweni zensimbi. Yiqiniso, okwamanje, kunezinhlobo ezimbili eziyisisekelo: Ishalofu elishiselwe kanye neshalofu elihlanganisiwe.

Iphalethi (ibhokisi lezimpahla): Iphalethi lisetshenziselwa kakhulu ukuthwala izimpahla, ngakho libizwa nangokuthi insimbi yesiteshi.

Isitaki somgwaqo: sisetshenziselwa ukufinyelela okuzenzakalelayo ezimpahleni. Ngokwesimo sayo sesakhiwo, singahlukaniswa sibe amafomu amabili ayisisekelo: ikholomu eyodwa kanye nekholomu kabili; Ngokwemodi yayo yesevisi, ingahlukaniswa ngezinhlobo ezintathu eziyisisekelo: umgwaqo oqondile, ijika kanye nemoto yokudlulisa.

Isistimu ye-Conveyor: isistimu ye-conveyor iyithuluzi eliyinhloko le-peripheral le-warehouse enezinhlangothi ezintathu, enesibopho sokuthutha impahla ukuya noma ukusuka ku-stacker. Yiqiniso, mayelana nesistimu yokuthutha, umenzi weshalofu lokugcina i-Hebei hegerls wenziwa ngokwezifiso kuphela. Ikhiqiza ikakhulukazi inhlobonhlobo yezinto zokusebenza zokuthutha, njenge-conveyor yesitimela, i-chain conveyor, itafula lokuphakamisa, imoto yokusabalalisa, i-elevator kanye ne-belt conveyor. Ngaphezu kwalokho, i-hegris iphinde ikhiqize futhi ikhiqize ezinye izinto zokugcina izinto, okuyi-forklift, i-pallet, isitsha, isitaki, njll., eziqeqeshelwa izikhungo zobuchwepheshe, ukukhiqizwa kochwepheshe, ukukhiqizwa kochwepheshe.

Isistimu ye-AGV: okungukuthi, imoto eqondisayo ezenzakalelayo, ehlukaniswe yaba yimoto eqondisayo nemoto eqondisayo ye-laser ngokuya ngemodi yayo yokuqondisa.

Isistimu yokulawula okuzenzakalelayo: iwuhlelo lokulawula oluzenzakalelayo olushayela zonke izisetshenziswa zohlelo lwe-auto-dimensional warehouse system. Ngokusho kokusebenza kwamanje, imodi ye-fieldbus isetshenziswa kakhulu njengemodi yokulawula.

Uhlelo lokuphathwa kolwazi lwempahla (i-WMS): eyaziwa nangokuthi uhlelo lokuphatha ikhompuyutha. Iwumgogodla wesistimu yomtapo wolwazi enezinhlangothi ezintathu ezizenzakalelayo. Njengamanje, isistimu yedatha ezenzakalelayo enezinhlangothi ezintathu isebenzisa isistimu yedatha enkulu (efana ne-Oracle, Sybase, njll.) ukuze kwakhiwe uhlelo olujwayelekile lweklayenti / iseva, olungaxhunywa kunethiwekhi noma luhlanganiswe nezinye izinhlelo (ezifana nesistimu ye-ERP , njll.).

Vele, isizathu sokuthi kungani i-AS-RS isetshenziswa amabhizinisi amaningi futhi kungenxa yezinzuzo zayo. I-Auto-dimensional warehouse ye-AS-RS ingathuthukisa izinga lokusetshenziswa kwesikhala sempahla yebhizinisi, yehlise indawo yokugcina impahla, yonge izindleko zokutshalwa kwezimali zomhlaba, futhi yakhe uhlelo oluthuthukisiwe lwezokuthutha ukuze kuthuthukiswe izinga lokukhiqiza nokuphatha lamabhizinisi. Ngesikhathi esifanayo, izophinde isheshise isigqi sokufinyelela sezimpahla ukuze kuqinisekiswe ukuthuthukiswa kokusebenza kahle kokukhiqiza. Ngaphezu kwalokho, i-AS-RS ingakwazi futhi ukubona ukusebenza kahle okuphelele kohlelo, ithuthukise izinga lokukhiqiza nokuphathwa kwempahla, futhi ibone ukuphathwa kwesikhathi sangempela kwempahla yokugcina impahla enqubweni yokwabiwa, okungagcini nje ukunciphisa umfutho wabasebenzi, ithuthukisa indawo yokusebenza yabasebenzi, yehlise izindleko zabasebenzi, kodwa futhi yehlise ukusalela emuva kwezimali zokusungula; Ngale ndlela, kusungulwa isizindalwazi sempahla esihlanganisiwe, esithuthukisa isisekelo esithembekile sakho konke ukugadwa kwezimpahla.

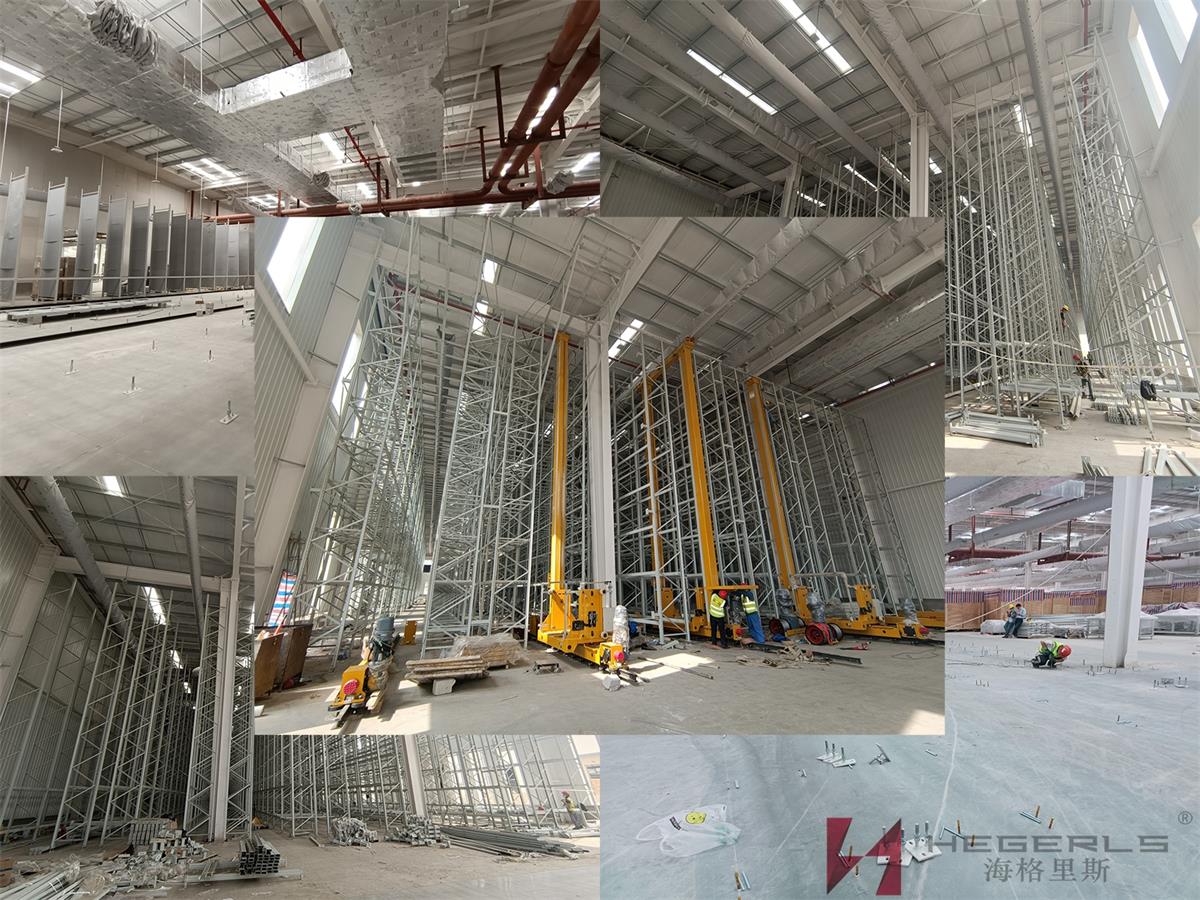

Ngale ndlela, inkinga iza nayo. Izinga lokusebenzisa isikhala se-automated-dimensional arehouse liphindwe izikhathi ezingu-2-5 kunelendlu yokugcina impahla eyifulethi. Izikhathi eziningi zomthamo wesitoreji zenza indawo yokugcina impahla enezinhlangothi ezintathu ibe enye yezinhlobo zamashalofu okulondoloza adumile okwamanje. Njengabenzi bezinqumo zebhizinisi, yiziphi izici okufanele sizicabangele ngaphambi kokuhlela ukutshala imali endaweni yokugcina izinto enezinhlangothi ezintathu? Okulandelayo, umkhiqizi weshalofu le-Hebei haigris hegerls uzoqhuba ukuhlaziya okuningiliziwe. Amalungiselelo adingekayo ngaphambi kokuklanywa kwe-AS-RS kuhlanganiswe ne-AGV / WCS / stacker ami kanje:

1) Kudingeka ukuqonda ukutshalwa kwezimali kwebhizinisi kanye nezinhlelo zabasebenzi zohlelo lwesitoreji, ukuze kunqunywe isikali sohlelo lokulondoloza kanye nezinga lemishini kanye ne-automation.

2) Ukuqonda izimo zesizinda sedamu, okuhlanganisa isimo sezulu, isimo sezulu, isimo sokwakheka komhlaba, umthamo wokuthwala umhlabathi, ukugcwala komoya neqhwa, ukuzamazama komhlaba neminye imithelela yemvelo.

3) Phenya futhi uqonde ezinye izimo ezihlobene nesistimu yokugcina izinto. Isibonelo, umthombo Wempahla Engenayo, izimo zethrafikhi ezixhuma igceke lesitolo, inombolo yeminyango engenayo nephumayo, ifomu lokupakisha, indlela yokuphatha, indawo yezimpahla eziphumayo nezinto zokuhamba, njll.

I-4) Indawo yokugcina impahla ezenzakalelayo iwuhlelo olungaphansi lwesistimu yezokuphathwa kwebhizinisi. Kufanele siqonde izimfuneko zalo lonke isistimu yezokuthutha yesistimu engaphansi kanye nokwakheka kwedizayini iyonke yesistimu yezokuthutha, ukuze senze umklamo jikelele wesistimu engaphansi yesitoreji. Phenya izinhlobo, amanani kanye nemithetho yezimpahla ezingaphakathi nangaphandle kweshede noma i-stockyard esikhathini esedlule, ukuze ubikezele ikusasa futhi ubale futhi uhlaziye umthamo we-warehouse.

I-5) Indawo yokugcina impahla ezenzakalelayo iyiphrojekthi enezigwegwe eziningi zemishini, ukwakheka, ubunjiniyela bukagesi kanye nobunjiniyela. Le mikhakha iyaphambana futhi ikhawulelana edizayini iyonke yendlu yokugcina impahla. Ngakho-ke, kufanele kucatshangelwe yonke imikhakha ekuklanyweni. Isibonelo, ukunemba kokunyakaza kwemishini kufanele kukhethwe ngokuya ngokunemba kokukhiqizwa kwesakhiwo kanye nokunemba kokuxazululwa kobunjiniyela bomphakathi.

6) Phenya igama lomkhiqizo, izici (ezifana nokuntekenteke, ukwesaba ukukhanya, ukwesaba umswakama, njll.), umumo nosayizi, isisindo sesiqephu esisodwa, i-inventory evamile, i-inventory ephezulu, inani elingenayo lansuku zonke elingenayo neliphumayo, indawo yokugcina impahla kanye nemvamisa ephumayo, njll. wezimpahla ezigcinwe endaweni yokugcina impahla.

Okungenhla yizindaba ezithile okufanele izicabangele ibhizinisi ngaphambi kokuthatha isinqumo sokutshala imali ku-warehouse enezinhlangothi ezintathu ezizenzakalelayo, okuhlanganisa nezindaba ezithile zobungcweti. Ungakwazi ukuxhumana ngokuqondile nomhlinzeki weshelufu le-warehouse (njengomkhiqizi weshelufu we-hebeihai Gris herls), ucele omunye umuntu ukuthi ahlaziye futhi aphenye ukusebenza kahle kwephrojekthi, futhi ekugcineni uqinisekise ukuthi uhlelo lwephrojekthi luyenzeka yini ukugwema umsebenzi ongasebenzi.

Isikhathi sokuthumela: May-11-2022