Emphakathini wanamuhla, umhlaba uya ngokuya uba yigugu futhi uyindlala. Indlela yokubeka izimpahla eziningi ngangokunokwenzeka endaweni elinganiselwe kuyinkinga ecatshangwa ngamabhizinisi amaningi. Ngokuthuthuka kwezikhathi, ukusetshenziswa kwensimbi kuye kwanda kakhulu. Isakhiwo ngokuyinhloko esenziwe ngensimbi singenye yezinhlobo ezibaluleke kakhulu zezakhiwo zokwakha. Yiqiniso, ngokuthuthukiswa komnotho kanye nesidingo esiphuthumayo samabhizinisi amakhulu, amashalofu esiteji sensimbi asetshenziswe ngobuningi. Khona-ke, kuzoba nezinkinga, njengokuthi ingabe inqolobane yebhizinisi isebenzisa amashalofu esiteji sensimbi noma amanye amashalofu okugcina? Uyini umehluko phakathi kwaleli shelufu lesikhulumi sensimbi namanye amashalofu? Hlobo luni lwesondlo oludingekayo ukuze kusetshenziswe nsuku zonke amashalofu esiteji sensimbi? Manje, vumela umenzi wamashalofu okugcina i-Hergels akutshele umehluko nokugcinwa kokuphepha phakathi kwamashalofu epulatifomu yensimbi namanye amashalofu!

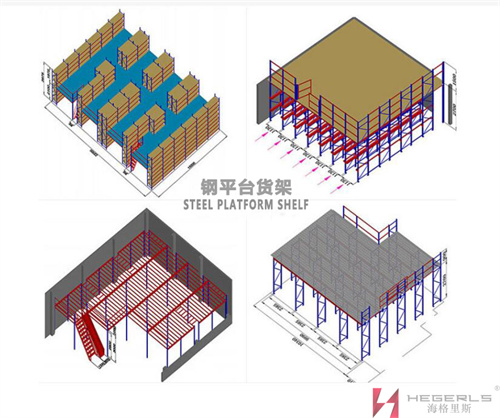

Amashalofu esiteji sensimbi, awaziwa nangokuthi amapulatifomu okusebenza, ayizakhiwo zobunjiniyela ezenziwe ngensimbi, ngokuvamile ezakhiwe ngamapulangwe, amakholomu, amapuleti nezinye izingxenye ezenziwe ngensimbi yesigaba kanye namapuleti ensimbi; Zonke izingxenye zixhunywe ngama-welds, izikulufu noma ama-rivets. Amashalofu esiteji sensimbi yesimanje anezakhiwo nemisebenzi ehlukahlukene. Isici saso sesakhiwo siyisakhiwo esihlangene ngokugcwele esinomklamo oguquguqukayo, osetshenziswa kabanzi ekugcinweni kwesimanje. Isiteji sesakhiwo sensimbi ngokuvamile sakha isiteji sesakhiwo sensimbi esinezitezi ezimbili noma esinezitezi ezintathu esihlanganiswe ngokugcwele endaweni yokusebenzela (i-warehouse) ekhona, ukushintsha indawo yokusetshenziswa kusuka esitezi esisodwa kuya kwezimbili noma ezintathu, ukuze kusetshenziswe ngokugcwele indawo. Izimpahla zithuthelwa esitezi sesibili nasesitezi sesithathu ngeforklift noma ngekheshi lezimpahla lesiteji sokuphakamisa, bese ziyiswa endaweni ebekiwe ngetroli noma iloli ye-hydraulic pallet. Uma kuqhathaniswa neplatifomu kakhonkolo eqinisiwe, le nkundla inezinzuzo zokwakha okusheshayo, izindleko ezimaphakathi, ukufakwa okulula nokuhlakazwa, kulula ukuyisebenzisa, kanye nenoveli nesakhiwo esihle. Ibanga phakathi kwamakholomu ale nkundla ngokuvamile liphakathi kuka-4-6m, ukuphakama kwesitezi sokuqala cishe ku-3M, kanti ukuphakama kwesitezi sesibili nesesithathu cishe ku-2.5m. Amakholomu ngokuvamile enziwa ngamashubhu ayisikwele noma amashubhu ayindilinga, imishayo eyinhloko neyizisekelo ngokuvamile yenziwa ngensimbi emise okuka-H, i-slab yaphansi ngokuvamile yenziwe nge-slab yaphansi egoqelwe ebandayo, i-floor slab enephethini eqinile, igridi yensimbi, kanye umthwalo waphansi ngokuvamile ungaphansi kuka-1000kg ngemitha yesikwele. Lolu hlobo lwesikhulumi lungahlanganisa ukugcinwa kwempahla nokuphatha ebangeni eliseduze. Isitezi esiphezulu noma esingaphansi singasetshenziswa njengamahhovisi okugcina impahla. Amasistimu anjalo asetshenziswa kakhulu ku-logistics yenkampani yangaphandle, ukukhiqizwa kwemishini nezinye izimboni.

Kulolu hlobo lwesistimu yeshalofu, kufanele siqale senze i-containization kanye ne-unitization, okungukuthi, ukupakisha izimpahla nesisindo sazo nezinye izici, sinqume uhlobo, ukucaciswa nobukhulu be-pallet, kanye nesisindo esisodwa kanye nokuphakama kwe-stacking ( isisindo esisodwa ngokuvamile singaphakathi kuka-2000kg), bese sinquma ukujula kwe-span kanye nesikhala sesendlalelo seshalofu leyunithi ngokuya ngobude obusebenzayo kanye nemfoloko yonqenqema olungezansi lwe-truss yophahla lwempahla. Ubude bezimfoloko zamaloli bunquma ubude bamashalofu. Ubude bamashalofu amayunithi ngokuvamile bungaphansi kuka-4m, ukujula kungaphansi kuka-5m, ukuphakama kwamashalofu ezindaweni zokugcina izinto eziphakeme ngokuvamile kungaphansi kuka-12M, futhi ukuphakama kwamashalofu ezindlini zokugcina izimpahla eziphakeme ngokuvamile kungaphansi kwama-30m (anjalo. izindawo zokugcina impahla ngokuyisisekelo ziyizindawo zokugcina izimpahla ezizenzakalelayo, futhi isamba sobude beshelufu sakhiwe ngamakholomu ayi-12). Lolu hlobo lwesistimu yeshalofu lunokusetshenziswa kwendawo ephezulu, ukufinyelela okuguquguqukayo, ukuphathwa kwekhompyutha okulula noma ukulawula, futhi ngokuyisisekelo lungahlangabezana nezidingo zohlelo lwesimanje lwempahla.

Amashalofu epulatifomu yensimbi - imininingwane iqinisekisa ukusetshenziswa okuphephile kwamashalofu

Ikholomu - khetha ipayipi eliyindilinga noma ipayipi eliyisikwele elinamandla okuthwala;

Imishayo eyisisekelo neyesibili - khetha insimbi evame ukusetshenziswa kakhulu e-H ezakhiweni zensimbi ngokuya ngezidingo zokuthwala;

Iphansi - indawo ephansi ine-checkered steel plate, ibhodi lezinkuni, i-hollow steel plate noma i-steel grating floor ongakhetha kuzo, engahlangabezana nezidingo ezihlukene zokuvimbela umlilo, ukungena komoya, ukukhanyisa nokunye.

Steel platform rack - izinto ezisizayo

Izitebhisi, ama-slides - izitebhisi zisetshenziselwa opharetha ukuhamba ukuya esitezi sesibili nesesithathu. I-slide isetshenziselwa ukushelela izimpahla ukusuka phezulu kuya phansi, okusindisa kakhulu izindleko zabasebenzi;

Isiteji sokuphakamisa - esetshenziselwa ukuthutha impahla phezulu naphansi phakathi kwaphansi, ukonga nokungokoqobo, enamandla amakhulu okuthwala kanye nokuphakamisa okuzinzile;

I-Guardrail - i-guardrail ifakwe endaweni engenabo udonga ukuze kuqinisekiswe ukuthi ngeke kube nezingozi zokuphepha kubasebenzi kanye nempahla;

I-Plywood yokhuni - phansi ifakwe nge-plywood yokhuni, ekwazi ukumelana nokucindezela, okuqinile, ukumelana nomthelela, umthwalo ozinzile, futhi igcina indawo;

Ipuleti le-steel gusset - ingaphezulu lensimbi ye-gusset plate ikhanya ngokuqhathaniswa, inomthwalo omuhle, ukumelana nomthelela nokusebenza kokuphepha;

Ipuleti lensimbi elinothayela – ipuleti lensimbi eliyisipesheli lensimbi eliyisipesheli eliyisipesheli le-gusset le-attic, elimelana nokuklwebheka, elingagugi, ubufakazi bokushelela kanye nesiqinisekiso sokuphepha.

Umthelela wokuqina kweshalofu yesikhulumi sensimbi ekuthwaleni umthwalo

Imishayo eyisisekelo neyesibili edingekayo ekwenzeni isiteji sesakhiwo sensimbi kufanele ibe namandla, futhi ukusekelwa kwesakhiwo seplatifomu yonke kuncike emigomeni eyinhloko neyesibili, ngakho-ke kufanele ibe namandla futhi iqine ekuthwaleni umthamo. Kunezici eziningi ezithinta ukuthwala umthwalo wesiteji sesakhiwo sensimbi. Ithintwa kakhulu ukwakheka kwamalungu, njengalokhu: isikhala sesakhiwo nosayizi wesigaba, izimo zesevisi, okungukuthi noma ukusetshenziswa kuyafinyeleleka, ngaphakathi nangaphandle, njll., umthwalo wesifunda, okungukuthi ukuhlinzeka ngendawo yokusetshenziswa, okuthinta umthwalo ophilayo, ukuzamazama komhlaba. umthwalo, umthwalo womoya, njll.

Uyini umehluko phakathi kwamashalofu epulatifomu yensimbi namanye amashalofu?

1) Isakhiwo esihlanganisiwe sithuthukisa ukusebenza kahle komsebenzi

Isitoreji kanye nehhovisi kungaklanywa njengesakhiwo esididiyelwe, ukuze kuthuthukiswe ukusebenza kahle komsebenzi. Ingabuye ifakwe izinto zokukhanyisa, izinto zokucisha umlilo, izitebhisi zokuhamba, amaslayidi ezimpahla, amakheshi nezinye izinto zokusebenza.

I-2) Isakhiwo esihlanganiswe ngokugcwele sinezindleko eziphansi kanye nokwakhiwa okusheshayo

Ishalofu le-attic licubungula ngokugcwele izinto ezisetshenziswa abantu, futhi linesakhiwo esihlanganiswe ngokugcwele, esilungele ukufakwa nokuhlakazwa, futhi singaklanywa ngendlela eguquguqukayo ngokuya ngokwendawo yangempela kanye nezidingo zempahla.

3) Umthwalo ophezulu kanye ne-span enkulu

Isakhiwo esiyinhloko senziwe nge-I-steel futhi sihlanganiswe nezikulufu, ezinokuqina okuqinile. Ubude bomklamo weplathifomu yensimbi bukhulu kakhulu, obungabeka izingcezu ezinkulu ezifana nama-pallet, futhi zingasetshenziselwa ukusetshenziswa kwehhovisi, kanye namashalofu amahhala. Iguquguquka kakhulu futhi iyasebenza, futhi isetshenziswa kabanzi kuzo zonke izinhlobo zezindawo zokugcina izimpahla zasefekthri.

4) Qondanisa ukuphathwa kwendawo yokugcina impahla futhi wonge izikhundla

Nakuba ilondoloza izikhundla, ithuthukisa izinga lokushintshwa kwezinto ezibonakalayo, yenza kube lula ukuqoqwa kwezinto ezibonakalayo, iphinda kabili izindleko zabasebenzi bokuphathwa kwempahla, futhi ithuthukisa ngokugcwele izinga lokuphatha kanye nokuphathwa kwempahla yebhizinisi.

Ukugcinwa kokuphepha kweshalofu yesikhulumi sensimbi

1) Isiteji sensimbi sizohlinzekwa ngepuleti lomkhawulo womthwalo.

I-2) Indawo yokubeka kanye nephoyinti elingaphezulu lethayi lesiteji sensimbi kufanele libekwe esakhiweni, futhi akufanele libekwe ku-scaffold nezinye izakhiwo zokwakha, futhi uhlelo lokusekela ngeke luxhunywe ne-scaffold.

3) Ugongolo lukakhonkolo kanye ne-slab endaweni yokubeka ishelufu yesikhulumi sensimbi kufanele kushumekwe futhi kuxhunywe namabhawodi epulatifomu.

4) I-engeli evundlile ifakiwe phakathi kwentambo yensimbi yensimbi neplathifomu kufanele ibe ngu-45 ℃ kuya ku-60 ℃.

I-5) Amandla aqinile wemishayo namakholomu amalunga okungezwani engxenyeni engenhla yesikhulumi sensimbi kufanele ahlolwe ukuze kuqinisekiswe ukuphepha kwesakhiwo kanye nesiteji.

6) Indandatho ye-snap izosetshenziselwa isiteji sensimbi, futhi ihuku akufanele lixhumane ngqo nendandatho yesikhulumi.

I-7) Uma isiteji sensimbi sifakiwe, intambo yensimbi yensimbi kufanele ifakwe ngokuqinile ngezingwegwe ezikhethekile. Lapho kusetshenziswa ezinye izindlela, akufanele kube namabhakede angekho ngaphansi kwama-3. Intambo yensimbi ezungeze ekhoneni elibukhali lesakhiwo kufanele ifakwe ama-cushions athambile, futhi ukuvulwa kwangaphandle kweplatifomu yensimbi kufanele kube phezulu kancane kunohlangothi lwangaphakathi.

I-8) Izandla ezigxiliwe kufanele zibekwe ohlangothini lwesobunxele nakwesokudla sepulatifomu yensimbi, futhi amanetha okuphepha aminyene kufanele alengiswe.

Umkhiqizi weshalofu we-Hagerls

I-Hagerls ingumkhiqizi ohlanganyela ekukhiqizeni amashalofu okugcina aminyene, imishini yokugcina izinto ezihlakaniphile namashalofu esindayo okugcina. Ineminyaka engaphezu kwengu-20 yokuhlangenwe nakho ekukhiqizeni isitoreji ngokwezifiso, ukuhlelwa kwesitoreji okuhlakaniphile okuhlukahlukene, futhi inikeza izinsizakalo ezihlanganisiwe zamashalofu. Imikhiqizo yethu eyinhloko yilezi: ishalofu le-Shuttle, ishalofu le-boam, ishalofu le-shuttle yezindlela ezine, ishalofu le-attic, ishalofu yesikhulumi sensimbi, idrayivu eshalofini, ishalofu lesakhiwo sensimbi, ishalofu elicacile, ishalofu lamandla adonsela phansi, ishalofu, ishalofu elincane, ishalofu lokujula kabili, njll. uma unentshisekelo kumashalofu ethu okugcina nezinto zokusebenza, sicela ukhululeke ukuxhumana nenkampani yethu, Sibheke phambili ekuhlinzekeni ngezinsizakalo zokuhlela isitoreji kumakhasimende avela emhlabeni wonke!

Isikhathi sokuthumela: Jul-27-2022