Ngokuthuthuka okusheshayo kwemboni yezokuthutha, i-pallet four-way shuttle rack eyi-three-dimensional warehouse isithuthuke yaba enye yezindlela ezijwayelekile zokugcinwa kwempahla ngenxa yezinzuzo zayo zokusebenza kahle nangokujulile kokugcinwa, izindleko zokusebenza kanye nokuphathwa okuhlelekile nokukhaliphile. uhlelo lokujikeleza nelokugcina. Eminyakeni yamuva nje, i-hegerls intelligent pallet four-way shuttle shelf izuze umusa wamabhizinisi amaningi, futhi iqongelele ulwazi oluthile lokusebenzisa amandla amasha, ukukhiqiza okuhlakaniphile, ezokwelapha, izicathulo nezinye izimboni. Ngakho-ke, amakhasimende ebhizinisi angakayisebenzisi ishelufu le-pallet shuttle le-haigris elinezindlela ezine kufanele abuze ukuthi i-haigris ingaqinisekisa kanjani ukuthi uhlelo lweshelufu le-four-pallet shuttle lungasebenza kahle? Manje, kusukela ezicini nasekuklanyeni okusebenzayo kweshelufu ye-pallet ye-shuttle four-way, i-haigris ihlaziya ngokuqondile futhi iphendule ukuthi i-haigris ingaqinisekisa kanjani ukusebenza kahle kwe-pallet ye-four-way shuttle shelf system?

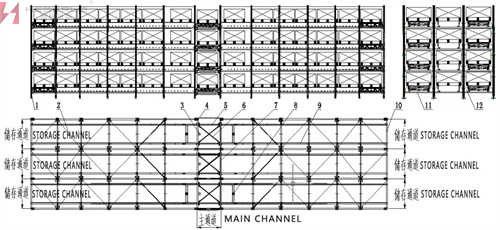

I-pallet ye-four-way car rack iyi-pallet ye-shuttle rack ye-pallet, eyakhiwe ikakhulukazi izingcezu eziqondile, imishayo esekelayo, ama-sub rails, ama-rail abazali, izinsimbi zokudonsa, izisekelo zokugcina, ama-rails ahlehlayo, njll.

1 – ikholomu ucezu 2 – uthayi ovundlile wethrekhi encane 3 – isekela lokubeka ugesi wesithombe 4 – ujantshi ovikelayo ekupheleni kweshaneli eyinhloko 5 – umzila wesitimela ohlehlayo 6 – uthayi ophambanayo kaloliwe ohlehlayo 7 – ithrekhi enkulu (irempu) 8 – ukushaja inqwaba 9 - ithrekhi encane (umhubhe) 10 - ujantshi ovikelayo ekupheleni kwesiteshi esincane 11 - ugongolo olusekela 12 - ukuphela kokusekelwa

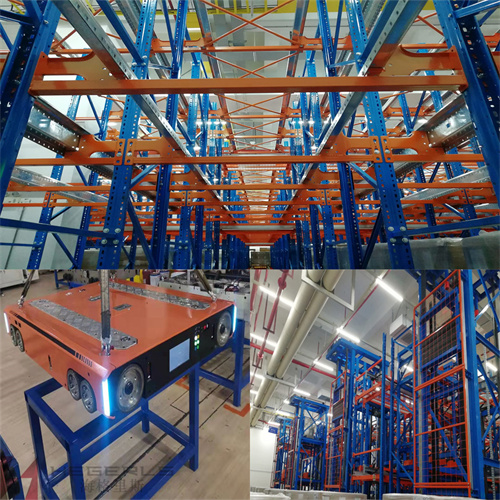

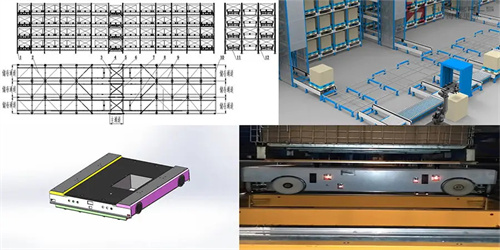

I-pallet four-way shuttle othomathikhi isistimu yokugcina eminyene iyisisombululo esisha sesistimu yokugcina okuzenzakalelayo. Ingakwazi ukubona imisebenzi yesitoreji esizenzakalelayo ngokusebenzisa ukucushwa okuguquguqukayo. Ingalungiswa njenge-shuttle rack rack eminyene, indawo yokubeka impahla enezinhlangothi ezintathu ezizenzakalelayo, kanye nezinhlelo ezihlukahlukene zokuhamba. Uhlelo lufanele ukuguqulwa okuzenzakalelayo kwendawo yokugcina impahla ephansi, indawo yokugcina impahla enamakholomu amaningi kakhulu kanye nendawo yokugcina impahla enesimo esingajwayelekile. Ngokwezidingo zangempela zokusebenza kahle, inani lezinto zokusebenza lingacushwa ngokunengqondo ngokwezidingo, ukuze kuxazululwe ububi bezindleko eziphezulu zokunakekela kanye nesakhiwo semishini esiyinkimbinkimbi sendawo yokugcina impahla enezinhlangothi ezintathu ezizenzakalelayo.

Q: njengomhlinzeki ohlakaniphile wezinto zokuthutha, yiziphi izici zohlobo lwe-pallet ye-shuttle rack ehlakaniphile eklanywe futhi yakhiqizwa ama-hegerls?

I-1) I-shuttle ye-pallet ye-four-way inesakhiwo esihlangene: ubude obuncane nobukhulu, igcina isikhala esiningi sokugcina; Ayikwazi ukuhamba ngezindlela ezine kuphela kuthrekhi yokubeka esekelayo, kodwa futhi isebenzise ikheshi eqondile ukuze ibone ukusebenza kokuguqula ungqimba, okwandisa ngokwengeziwe ukuguquguquka nokuqina kwesakhiwo se-warehouse rack kanye nokusebenza egaraji le-shuttle yezindlela ezine.

2) Indlela emine yokuhamba: ingahamba ngamathrekhi aqondile noma avundlile kuthrekhi yokuwela irekhi enezinhlangothi ezintathu ukuze ithole izinto zokuhamba ezisuka endaweni eyodwa ukuya endaweni eyodwa, futhi ingafinyelela noma iyiphi indawo endaweni yokugcina impahla;

I-3) Ukushintshwa kwesendlalelo esihlakaniphile: ngosizo lwe-higris elevator, imoto ye-shuttle ingakwazi ukubona imodi yokusebenza ephumelelayo yokushintshwa kongqimba okuzenzakalelayo nokunembile; Qaphela ukunyakaza kwezinhlangothi ezintathu esikhaleni futhi ulawule ngokunembile indawo yokugcina impahla kanye nokuphumayo kwendawo ngayinye yempahla endaweni yeshalofu lensimbi;

4) Ukulawula okuhlakaniphile: kunezindlela zokusebenza ezizenzakalelayo ne-semi-automatic. Ithuthukisa kakhulu ukusebenza kahle kwezimpahla ezingenayo kanye nokusetshenziswa kwesikhala kwendawo yokugcina impahla. Ukumiswa kwesofthiwe yesistimu ye-WMS kanye ne-WCs ene-ERP / SAP / MES yebhizinisi kanye nezinye isofthiwe yesistimu yokuphatha kungagcina futhi indlela yokuqala yokuphuma yokugcina impahla, futhi kuqede ukuphazamiseka noma ukusebenza kahle okuphansi kwezici zomuntu;

5) Izinga eliphezulu lokusetshenziswa kwendawo yokugcina impahla: ukuminyana kwendawo yokugcina impahla kuncane, okuholela ekusetshenzisweni okuphansi kwenani lendawo yokugcina impahla kanye nezinga eliphansi lokusetshenziswa kwenani lempahla; I-pallet ye-shuttle ye-four-way ihamba ngezindlela ezine kumzila oyinhloko ku-rack, futhi ingaqedela ukusebenza ngokuzimela ngaphandle kokuxhumana kwe-forklift nezinye izinto zokusebenza. Njengoba ivolumu yethrekhi eyinhloko ye-rack incane kunomthamo wesiteshi sokusebenza kwe-forklift, i-pallet ye-shuttle ye-othomathikhi yesistimu yokugcina i-shuttle ezenzakalelayo ingathuthukisa izinga lokusetshenziswa kwendawo yokugcina uma kuqhathaniswa nesistimu yokubeka imoto evamile, okuyinto. ngokuvamile ingakhuphuka ngo-20% ~ 30%, okuyizikhathi ezi-2 ~ 5 kunezokugcina impahla eyisicaba;

6) Ukuphathwa okunamandla kwendawo yezimpahla: indawo yokugcina impahla yendabuko iyindawo kuphela lapho kugcinwa khona izimpahla, futhi ukugcinwa kwempahla kuwumsebenzi wayo kuphela. Kuwuhlobo "lwesitoreji esimile". I-pallet four-way shuttle car iyisisetshenziswa esithuthukisiwe sokuphatha izinto ezizenzakalelayo, esingakwazi nje ukwenza izimpahla zigcinwe ngokuzenzakalelayo endaweni yokugcina izimpahla ngokwezidingo, kodwa futhi zixhumeke ngokwezinto eziphilayo nezixhumanisi zokukhiqiza ngaphandle kwendawo yokugcina izinto, ukuze kwakhiwe i-Advanced. uhlelo lokuphatha kanye nokwenza ngcono izinga lokuphatha lebhizinisi;

I-7) Imodeli ye-warehouse ezenzakalelayo engasebenzi: inciphisa kakhulu umsebenzi wabasebenzi be-warehouse futhi inikeza amathuba omsebenzi ongenamuntu endaweni yokugcina impahla. Indawo yokugcina impahla enezinhlangothi ezintathu yokulethwa komkhiqizo ixhunywe ngokuqondile ngomshini wephalethi wokuya nokubuya, i-lift eqondile yezimpahla kanye nesithuthi esizenzakalelayo. Abasebenzi be-warehouse badinga kuphela ukuqapha ukusebenza kwesistimu ngaso sonke isikhathi ukuze babone ukufinyelela okuzenzakalelayo, futhi asikho isidingo sokungena endaweni yokugcina impahla ukuze isebenze. Ifaneleka ngokukhethekile ukugcinwa kwezindawo zokugcina izinto ezingafanelekile ukuboshwa isikhathi eside kwabasebenzi, Kuyisiqondiso sokuthuthukiswa kwesitoreji esiphezulu kanye nendawo yokugcina impahla ezenzakalelayo esikhathini esizayo.

I-8) Imvelo yokushisa: ishalofu le-pallet eline-shuttle ye-shuttle elikhiqizwa ama-hegerls lingakwazi futhi ukufeza izindlela ezimbili zemvelo: ukusebenza okuvamile ngaphansi kwesitoreji esiphezulu sokushisa kanye nokugcinwa kwezinga lokushisa eliphansi.

I-9) Ukusebenza kokuphepha: sebenzisa i-hardware yamazinga amaningi kanye nezinhlelo zokuqapha ezihlanganisiwe zesoftware, setha ibanga eliphephile lokusebenza nezimiso zokwahlulela, futhi uqinisekise ukusebenza okuphephile kwemoto yonke ngokusebenzisa isivimbeli somkhawulo wokusebenza esithile noma indlela yokulwa nokugumbuqela.

Umbuzo: ngaphezu kwalezi zici ezingenhla, yiziphi izici zeshalofu le-pallet ye-four-way shuttle kumklamo othize wokusebenza ukuze kuqinisekiswe ukusebenza kahle kwesistimu yeshalofu ye-shuttle ye-pallet ye-four-way?

I-rack yeloli ye-shuttle ye-four-way ye-haigris pallet ine-mode eyingqayizivele yokuqala ye-motor kanye ne-deceleration, engakwazi ukubona ukusebenza okuzinzile ngaphansi kokusheshisa okuphezulu nokunciphisa. Ngesikhathi esifanayo, futhi inemodi ekhethekile yokushaja okukabili yokushaja okuqondile nokushaja okungenantambo. Imodi yokushaja eqondile ifanele izindawo ezivamile zokukhiqiza; Imodi yokushaja okungenantambo ifanele indawo evikela uthuli futhi ingaqhumi.

Izici zokuklama ezisebenzayo ze-rack yeloli ye-shuttle ye-haigris pallet yilezi ezilandelayo:

Ukuqhubeka kwe-Breakpoint: lapho imoto yenza umsebenzi wokulayisha nokulayisha, ngenxa yokwehluleka kwesikhashana okungeyona i-hardware njengokugwema izithiyo nokunqanyulwa kwenethiwekhi, imoto izoqhubeka ngokuzenzakalela ukwenza umsebenzi ongaqediwe ngaphandle kokungenelela komuntu ngemuva kokulinda endaweni yokuqala kuze kube okungavamile kuyaqedwa.

Ukushaja okuzenzakalelayo nokubuyela emsebenzini: uma imoto ingaphansi kwenani eliphansi lebhethri elibekiwe, ulwazi olufanele lwebhethri luzolayishwa ngokuzenzakalelayo kuma-WC, futhi ama-WC azothumela imoto ukuze yenze umsebenzi wokushaja. Ngemva kokuba imoto ishajwe enanini lamandla amisiwe, ulwazi lwamandla olufanele luzolayishwa ngokuzenzakalelayo kuma-WC, futhi ama-WC azothumela imoto ukuze iqalise kabusha umsebenzi.

Umbono we-pallet: imoto inemisebenzi yokulinganisa i-pallet centering kanye nokutholwa kwe-pallet

Umbono wezithiyo: imoto inomsebenzi wokubona izithiyo ezinhlangothini ezine, futhi ingagwema izithiyo ebangeni elide futhi ime ebangeni elifushane.

Inzwa yokushisa yebhethri: ithola izinga lokushisa lebhethri emzimbeni wemoto ngesikhathi sangempela. Uma izinga lokushisa lebhethri lidlula umkhawulo ophezulu omisiwe, libuyisela ulwazi lwezinga lokushisa lebhethri elingavamile ku-WCS ngesikhathi sangempela. I-WCS ithumela izimoto esiteshini esikhethekile esingaphandle kwendawo yokugcina izimpahla ukugwema umlilo.

Umsebenzi wokuhlehla we-in situ: qaphela ukuhlehla kwe-in-situ yomzimba wemoto ngokushintsha amasondo ahambisanayo nhlangothi zombili.

Indlela emine yokuhamba: ingahamba izinhlangothi ezine zethrekhi enikelwe yendlu yokugcina impahla enezinhlangothi ezintathu futhi ifinyelele noma iyiphi indawo emisiwe yendlu yokugcina impahla ngaphansi kokuthunyelwa kwe-WCS.

Ukulinganisa indawo: Ukutholwa kwezinzwa eziningi, okulekelelwa ikhodi yomhubhe enezinhlangothi ezimbili, ukuze kuzuzwe ukuma okunembile.

Imodi yokulawula ukuthunyelwa okuhlakaniphile: Imodi yokuthumela okuzenzakalelayo ye-WCS eku-inthanethi, imodi yokusebenza yesilawuli kude semanuwali kanye nemodi yokulungisa.

Imodi yokulala nokuvuka: ngemva kokulinda isikhathi eside, faka imodi yokulala ukuze wonge amandla. Uma idinga ukusebenza futhi, izovuka ngokuzenzakalelayo.

Ukuhlenga ukunikezwa kwamandla okuphuthumayo: ngaphansi kwezimo ezingavamile, lapho amandla ebhethri enguziro, sebenzisa ugesi wezimo eziphuthumayo, vula ibhuleki lemoto, bese uhambisa imoto endaweni yokunakekela ehambisanayo.

Ukuboniswa kwesimo kanye ne-alamu: amalambu okubonisa isimo afakwa ezindaweni eziningi zemoto ukuze abonise ngokucacile izimo ezihlukahlukene zokusebenza kwemoto. Kufakwe i-buzzer ukunikeza i-alamu uma imoto yehluleka.

Ukutholwa kokushaja: lapho imoto ifika endaweni yokushaja, ukushaja okungavamile kwenzeka phakathi nokushaja, futhi ulwazi olungavamile lubuyiselwa ku-WCS ngesikhathi sangempela.

Ukumuncwa ukushaqeka kwemoto: amasondo akhethekile e-polyurethane asetshenziselwa ukumelana nokucindezela, ukumelana nokugqoka, ukumelana nokucindezela nokumunca ukushaqeka.

Isikhathi sokuthumela: Aug-25-2022