Muva nje, u-Hergels uzibophezele ekuhlinzekeni ngezixazululo ezizenzakalelayo, ezihlakaniphile, eziguquguqukayo futhi ezenziwe ngezifiso ngamarobhothi nama-algorithms obuhlakani bokwenziwa, nokudala inani lefekthri ngayinye nendlu yokugcina izinto. Ifinyelele ohlotsheni olusha lwephrojekthi yokubambisana ne-Hergels innovation, futhi yakha uhlelo lwe-ACR (irobhothi lokugcina ibhokisi) oluthuthukiswe ngokuzimela u-Hergels innovation. I-ACR inamayunithi okusebenza amancane kanye nezinga eliphezulu lokushaya, elifaneleka kakhulu izimboni ezinomthamo omncane wezimpahla, iqoqo elincane nama-SKU amaningi. Ngaphezu kwalokho, ukuthunyelwa kwemishini kunezidingo eziphansi zemvelo, izindleko eziphansi zokutshala izimali, futhi umjikelezo wokulethwa uvame ukuba phakathi nenyanga eyodwa. Ngakho-ke, ingabuye iguqulwe ngokuguquguqukayo futhi yandiswe ngokuvumelana nezinguquko zebhizinisi, okusho ukuthi amakhasimende angakwazi ukufeza ukwakhiwa okusebenzayo kwendawo yokugcina impahla yamarobhothi ngesikhathi esifushane nangezindleko eziphansi. Ngasikhathi sinye, futhi kuwuhlelo lokuqala lwamarobhothi okugcinwa kwebhokisi okufanele lusetshenziswe kwezohwebo, olusetshenziswe kumaphrojekthi angama-500 + ekhaya naphesheya.

Mayelana nesistimu ye-kubao

Uhlelo lwe-Kubao, olwaqala ukuthuthukiswa futhi lwasetshenziswa kwezentengiselwano kusukela ngo-2015, lusetshenziswe ku-3PL, izicathulo nezingubo, i-e-commerce, i-electronics, amandla kagesi, ukukhiqiza, ukwelapha kanye nezinye izimboni. Isistimu ye-ACR icabangela izinzuzo ezimbili "zokuguquguquka" okwengeziwe kwamarobhothi aphatha amaselula kanye "nokuminyana kwesitoreji" okuphezulu kwesakhiwo se-warehouse esiqinile. Izinzuzo ezintathu eziyinhloko zalo mkhiqizo yilezi: ungasiza amakhasimende ukwandisa ukuminyana kwesitoreji ngo-80% - 400%; Ingathuthukisa ukusebenza kahle kokuhlunga kwabasebenzi izikhathi ezi-3-4; Ngesikhathi esifanayo, ingakwazi futhi ukusekela ukuthunyelwa kwezinsuku ezingu-7 kanye nenyanga engu-1 ku-inthanethi, okunciphisa kakhulu izindleko nobunzima bokuguqulwa kwe-automation.

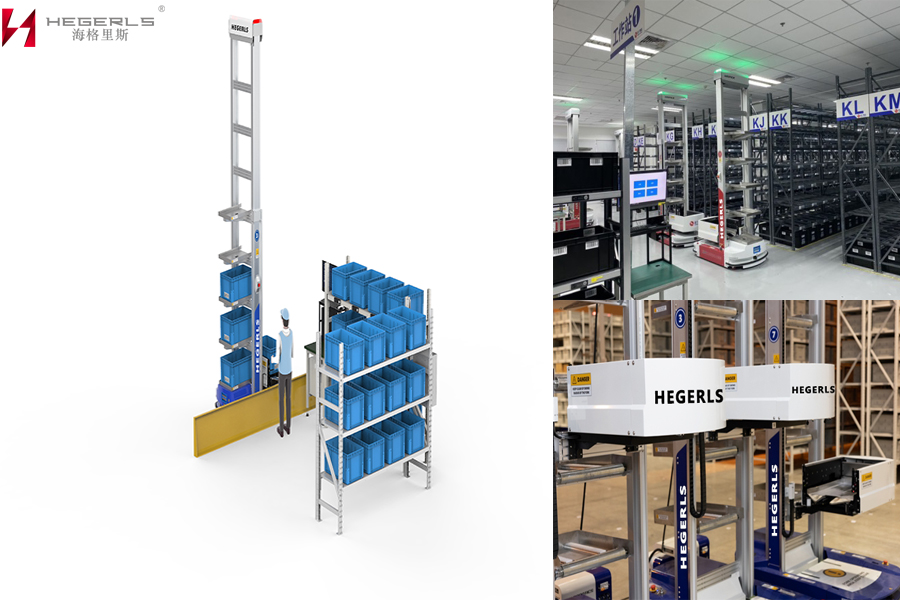

Uhlelo lwe-Kubao lwakhiwe ngerobhothi ye-kubao, ikhonsoli esebenza ngezinto eziningi, inqwaba yokushaja ehlakaniphile, idivayisi yokugcina impahla kanye nesistimu yesofthiwe haiq. Irobhothi le-Kubao lamukela ukuma kwe-fusion yezinzwa eziningi, futhi ukunemba kokulawula kokuthatha nokubeka kungu-± 3mm. Iqaphela imisebenzi yokukhetha nokuphatha okuhlakaniphile, ukuzulazula okuzenzakalelayo, ukugwema izithiyo ezisebenzayo kanye nokushaja okuzenzakalelayo, futhi inezici zokuzinza okuphezulu nokusebenza okunembayo okuphezulu; Ikhonsoli enemisebenzi eminingi ingalungiswa ngemishini ehlukahlukene, okuhlanganisa i-manipulator, isistimu yokukha ukukhanya nomugqa wokuthutha, ukuze ihlangabezane nezidingo zezigcawu ezihlukahlukene. I-Haiq iwubuchopho obukhaliphile bohlelo oluhlakaniphile lokugcina impahla, olukwazi ukubona ukumiswa kwemikhumbi ngohlelo lokuphatha lwangaphandle, lubhekane nezidingo zebhizinisi ezifanele, luhlaziye idatha kanye nokuphathwa okubonakalayo; Qinisekisa ukuhlela kwesikhathi sangempela kwamarobhothi amaningi kanye nemishini ehlukahlukene, qaphela ukubikezela nokuqapha kwezempilo yesistimu, futhi uthuthukise isistimu ngokusekelwe ekufundeni kokuqinisa nokufunda okujulile. Njengamanje, esifuna ukukusho indawo yokusebenza yokukhetha umshini womuntu endaweni yokusebenza enemisebenzi eminingi.

Indawo yokusebenzela yokuhlunga eqondile ye-Hegerls:

Indawo yokusebenza yokukhetha ngokuqondile ngomshini womuntu yenziwe inkundla yokusebenza, i-Kanban ebonakalayo, ishalofu, nesistimu yokukha ukukhanya. Ixhunywe namarobhothi ochungechunge lwe-kubao, angakwazi ukubona ukuthi abasebenzi bakhethe ngokuqondile izimpahla ze-oda kubhasikidi wamarobhothi. Inezinzuzo zezindleko eziphansi, ukuguquguquka, nokuthunyelwa kalula. Endaweni yokusebenzela yokukha eqondile yomshini womuntu, opharetha ukhetha ngokuqondile ubhasikidi womshini, futhi udinga kuphela ukuhlonywa indawo yokusebenza kanye nesibhamu sokuskena ukuze aqedele ukukha. Isimo esisebenzayo: sisebenza kuzo zonke izimo, ikakhulukazi ekwandiseni okokusebenza kwesikhashana esikhathini esiphezulu se-e-commerce nemboni yezicathulo.

Izici ezisebenzayo ze-Hegels man-machine ngqo indawo yokusebenza yokukhetha:

Ukukhetha okuhlakaniphile - lungiselela i-Kanban ebonakalayo ukuze iqondise abasebenzi ukuze bahlele izimpahla;

Ukusebenza okulula - irobhothi alidingi ukuthulula isitsha, futhi abasebenzi bakhetha ngokuqondile izimpahla kubhasikidi we-robot;

Okungenayo nokuphumayo okuphumelelayo - irobhothi ngalinye linokuphatha kahle kwamabhokisi angama-30-35 / ihora + 30-35 amabhokisi / ihora, indawo yokusebenzela eyodwa inomphumela ophumayo wamabhokisi angama-350 / h, kanye nokusebenza kahle kokugcinwa kwempahla kwamabhokisi angama-200 / h.

Isixazululo esihlanganisiwe sesistimu ye-kubao kanye nendawo yokusebenza yokukhetha ngokuqondile umshini womuntu ingaba nezinzuzo zobumbudumbudu obucolisekileyo, iyunithi yokusebenza encane kanye nezinga eliphezulu lokushaya. Kumakhasimende, uma izinga lokuguquguquka liphezulu, inani elingakwazi ukukhiqiza liphezulu. Ngenkathi kunciphisa ukusebenza, kungaphinde kuthuthukise kakhulu ukuminyana kwesitoreji, ukukhetha ukusebenza kahle kanye nezinye izinkomba ezibalulekile zamafektri agcina izinto. Ngesikhathi esifanayo, ngokwezici zesistimu ye-kubao kanye nesixazululo se-automation ye-warehousing, ama-haggis herls "azofanelana nekhambi lecala" endaweni yalo yobuhlungu bendawo. Ngamarobhothi amaningi nezindawo zokusebenza eziningi, ukusebenza kahle okumaphakathi kwezindawo zokusebenza kuzokwenyuswa kube yizicucu ze-450, amandla okucubungula nsuku zonke azokwenyuswa abe yizicucu ze-50000, futhi amabhokisi angaphezu kwe-10 azogcinwa endaweni ngayinye, okuzokwandisa ukuminyana kwendawo yokugcina impahla ngo-2. izikhathi, kanye nekhono lokukhetha izikhathi ezi-3-4, okwandisa ukusebenza kahle.

U-Haggis ubelokhu ethatha ucwaningo nokuthuthukiswa kwamarobhothi okugcina impahla kanye nempahla kanye nokwandiswa kwamabhizinisi asekhaya nawakwamanye amazwe njengomsebenzi wawo oyinhloko, futhi wasebenzisa imikhiqizo esebenza kahle, ehlakaniphile futhi eguquguqukayo ukwenza yonke indawo yokugcina impahla isebenzise amarobhothi, ukuze avale ukushoda. zabasebenzi. Eminyakeni yamuva, ama-hagerl nawo abelokhu ekhulisa izimakethe zawo zasekhaya nezangaphandle. Njengamanje, siyabona ukuthi amabhizinisi emhlabeni wonke abhekene nezinselelo zokuhlinzeka ngempahla kanye nokushoda kwabasebenzi. Ngakho-ke, i-Hercules herls nayo isheshisa ukwakheka kwemakethe yamazwe ngamazwe futhi ijulisa ngokuqhubekayo ukuhlolwa kokubambisana kwamazwe ngamazwe. Kumakhasimende aphesheya kwezilwandle, ngaphansi kwezimo ezinzima zokuqashwa kwefekthri, ukukhuphuka kwezindleko zabasebenzi nezomhlaba, kanye nokungaqiniseki okwandayo endaweni yebhizinisi, uhlelo lwe-ACR lungakwazi ukuzivumelanisa nezidingo zokugcinwa kwempahla kanye nezidingo zamabhizinisi ahlukene ngenxa yobuhlakani balo, ukuguquguquka, ukusebenza kahle nokuningi. ezinye izinzuzo. Amarobhothi kanye ne-warehousing automation akusho nje kuphela inqubekelaphambili yemboni yezokuthutha, kodwa futhi kubonisa ukuthi ukugcinwa kwempahla kanye nempahla kuzoba seduze futhi kusondele ezimpilweni zabantu abavamile. U-Hergels uzimisele ukuqhubekela embonweni “wokwenza amarobhothi ezimpahla asebenze kuzo zonke izindawo zokugcina izimpahla nefekthri”, ukuze abantu abahlukene ngaphakathi nangaphandle kwemboni bathole izinzuzo futhi bakhule. Unyaka nonyaka, ama-hagerl azoqhubeka nokutadisha amaphuzu ezinhlungu zabasebenzisi nobunzima bezimboni, ibhalansi ukuminyana kwesitoreji nokusebenza kahle komkhumbi ngokuya ngezidingo zamakhasimende, futhi abe uphawu embonini kuyilapho esebenzela amakhasimende ethu kahle.

Isikhathi sokuthumela: Jul-11-2022