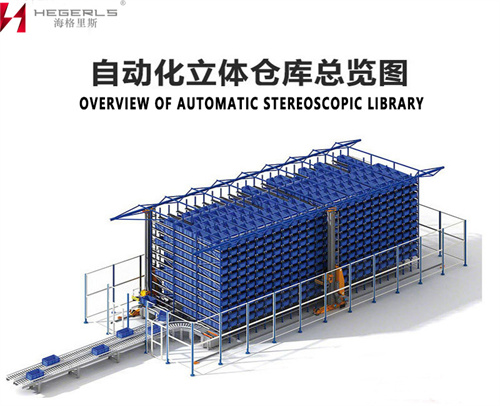

Ngokuthuthuka okusheshayo nokuhlanganiswa kwesayensi nobuchwepheshe kanye nempahla, inqolobane ezenzakalelayo enezinhlangothi ezintathu isiphenduke inketho enkulu yokugcina amabhizinisi amaningi. I-automatic-dimensional warehouse iyisistimu ye-warehouse ephakeme enezingqimba eziningi esetshenziselwa ukugcina izimpahla. Yakhiwe ngamashalofu anezinhlangothi ezintathu, izitaki, izinto zokuthutha, izinto zokusingatha, amaphalethi, amasistimu olwazi lokuphatha kanye nezinye izinto ezisetshenziswayo. Ingakwazi ukuqedela ngokuzenzakalelayo ukugcinwa kwezimpahla ngokwemiyalelo, futhi ingaphatha ngokuzenzakalelayo indawo yokusungula. Ibambe iqhaza elikhulu emabhizinisini esimanje. Indawo yokugcina impahla enezinhlangothi ezintathu ezizenzakalelayo isetshenziswa kabanzi ekukhiqizeni nasekusabalaliseni izinto zikagesi, imishini, imithi, izimonyo, ugwayi, izimoto nezinye izimboni. Ingathuthukisa izinga lokuphathwa kwempahla, ithuthukise ukusebenza kahle, inciphise umonakalo kanye nomehluko wezimpahla, yonge umhlaba, futhi yonge izinsiza zabantu, izinto ezibonakalayo kanye nezezimali.

Ukwakhiwa kwesakhiwo komtapo wolwazi we-auto-dimensional

*Ishalofu: Isakhiwo sensimbi esisetshenziselwa ukugcina izimpahla, ikakhulukazi okuhlanganisa ishalofu elishiselwe kanye neshalofu elihlanganisiwe.

*Iphalethi (isitsha): into esetshenziswa ukuthwala impahla, eyaziwa nangokuthi umshini wasesiteshini.

*I-Laneway stacker: okokusebenza okusetshenziselwa ukufinyelela okuzenzakalelayo ezimpahleni. Ingahlukaniswa ngezinhlobo ezimbili eziyisisekelo zekholomu eyodwa kanye nekholomu ephindwe kabili ngokusho kwesakhiwo sayo; Ngokwemodi yesevisi, ingahlukaniswa ngezinhlobo ezintathu eziyisisekelo: iqonde, ijika nemoto yokudlulisa.

*Isistimu ye-Conveyor: okokusebenza okuyinhloko kwangaphandle kwendawo yokugcina impahla enezinhlangothi ezintathu, enesibopho sokuthutha impahla isiya noma isuka kusitaki. Kunezinhlobo eziningi zokuthutha, ezifana ne-roller conveyor, chain conveyor, itafula eliphakamisayo, imoto yokusabalalisa, i-elevator, i-conveyor yebhande, njll.

*Isistimu ye-AGV: okungukuthi i-othomathikhi eqondiswayo, ehlukaniswe nge-induction guided trolley kanye ne-laser guided trolley ngokuya ngemodi yayo eyisiqondiso.

*Isistimu yokulawula okuzenzakalelayo: isistimu yokulawula okuzenzakalelayo eshayela amathuluzi esistimu yelabhulali enezinhlangothi ezintathu ezizenzakalelayo isekelwe ikakhulukazi kumodi yebhasi yasendle.

*Uhlelo lokulawulwa kolwazi lwesitoreji: olwaziwa nangokuthi uhlelo lokuphatha ikhompuyutha, luwumgogodla wohlelo lomtapo wolwazi olunezinhlangothi ezintathu ezizenzakalelayo. Izinhlelo zomtapo wolwazi ezizenzakalelayo ezinezinhlangothi ezintathu zisebenzisa amasistimu esizindalwazi esikhulu (njenge-Oracle, Sybase, njll.) ukuze akhe uhlelo olujwayelekile lweklayenti/lweseva, olungaxhunywa kunethiwekhi noma luhlanganiswe nezinye izinhlelo (ezifana nesistimu ye-ERP, njll.) .

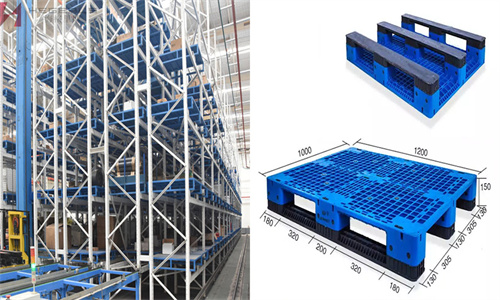

Lapho, ithreyi elomshini omncane wezinto ezisetshenziswayo. Abantu abaningi bacabanga ukuthi i-pallet iyithuluzi elilula elingenakho okuqukethwe kwezobuchwepheshe, futhi abayazi indima yayo ebalulekile ku-logistics ngisho nakuwo wonke uchungechunge lokuhlinzeka. Eqinisweni, embonini yezokuthutha, ama-pallets awakwazi kuphela ukuqinisekisa ukugeleza okujwayelekile, uxhumano olusebenzayo, inqubo ebushelelezi nephelele yemikhiqizo yamabhizinisi akhuphukayo naphansi ochungechungeni lokuhlinzeka, kodwa futhi athuthukise kakhulu ukusebenza kahle kokusebenza kwempahla nokunciphisa izindleko zempahla. Ukuqanjwa kabusha kokukhiqizwa kwe-pallet kubaluleke kakhulu ekongiweni kwezinsiza kanye nokuvikelwa kwemvelo.

Ku-arehouse ye-auto-dimensional three-dimensional, izinto ezisetshenziswayo zifakwa ku-pallet evamile, futhi i-pallet ithunyelwa endaweni ethile yomzimba we-warehouse ngokusebenzisa idivayisi yokuphakamisa ephakathi. I-pallet ejwayelekile ingenziwa ngokwezifiso ibe amafomu ahlukene ngokusho kobukhulu bangempela kanye nemvelo yezinto zokwakha ukuhlangabezana nezidingo zezimboni ezahlukene. Izingxenye eziyisipele ezihlakazekile, amadokhumenti, imikhiqizo ye-elekthronikhi, izidakamizwa, noma izingxenye zekhwalithi ephezulu zingabekwa ethreyini, futhi izinga lokushisa, umswakama, ukukhanya, njll. endaweni yokugcina impahla nakho kungalawulwa ukuze kwakhiwe umtapo wolwazi ngezinjongo ezahlukene, njenge umtapo wolwazi wezingxenye ezisele, umtapo wolwazi, umtapo wolwazi, umtapo wolwazi, umtapo wolwazi wezidakamizwa, izinga lokushisa elingaguquki kanye nomtapo womswakama, umtapo wolwazi wenqolobane, njll.

Ukusheshisa nokusebenza kahle kubalulekile uma ufuna ukuzuza inzuzo enkulu yempahla. Uma inani elikhulu lezinto lisebenza kusistimu ye-multi shift noma ligcinwe futhi licutshungulwa endaweni elinganiselwe, i-othomathikhi ye-pallet warehouse ihlale inikeza ukudlala ngezinzuzo zayo. Amaphalethi asetshenziswa nendawo yokugcina impahla enezinhlangothi ezintathu ezenzakalelayo angakwazi ukusebenzisa ngokunengqondo nangokugcwele indawo yeshede enezinhlangothi ezintathu, axhumane nohlelo olukhaliphile, abone inqubo egcwele yokuzenzakalela, anciphise abasebenzi, athuthukise ukusebenza kahle, enze indawo yokugcina ihlanzeke futhi iphephe kakhudlwana. , futhi ihlangabezane nezici zezimpahla ezifana nokuvikela ukukhanya, izinga lokushisa eliphansi, umswakama-ubufakazi kanye nokunqanda ukugqwala. Ngesikhathi esifanayo, uhlelo lweshalofu, isofthiwe nazo zonke izinto ezisetshenziswa ku-automated pallet warehouse kumele zihambisane ngokuphelele. Ngakho-ke, ukuhlelwa nokuqaliswa kwesitoreji se-pallet esizenzakalelayo kufanele kuqedwe ochwepheshe abanolwazi njenge-hegerls warehousing. I-othomathikhi ye-pallet warehouse ingasetshenziswa njengedivayisi eyakhelwe ngaphakathi yokugcina impahla noma indawo yokugcina impahla ye-silo, enobude obungama-45m, ngakho izinga lokusebenzisa isikhala liphezulu kakhulu. Isikhala sokubeka ithreyi, i-grille box kanye ne-personalized bearing system singakwazi ukumelana nomthwalo ongu-7.5t. Lezi zindawo zokugcina impahla zihlukaniswe ngokwezigaba ezine, ungqimba oluphindwe kabili kanye nezingqimba eziningi futhi zisebenza cishe kuzo zonke izinhlobo zemikhiqizo. Isetshenziswa njengendawo yokugcina izinga lokushisa elijwayelekile, indawo yokugcina impahla elawulwa izinga lokushisa noma indawo ebanda ebanda emazingeni okushisa aphansi aphansi -35 ° C.

Yiziphi izimfuneko zamathileyi omtapo wolwazi anezinhlangothi ezintathu ezizenzakalelayo?

*Ukucaciswa kwephalethi kuyadingeka ukuze kunqunywe kusengaphambili

Amakhasimende amaningi azocabangela lokhu lapho akha umtapo wolwazi onezinhlangothi ezintathu, ukuze angakhulisi izindleko kamuva. Kuphela ngemva kokuba usayizi we-pallet unqunywe kusengaphambili lapho okucaciswayo kwamashalofu angemuva anezinhlangothi ezintathu zokugcina impahla kungalungiswa, okokusebenza okufana ne-stacker, umugqa wokuhlanganisa kanye nemoto ye-shuttle kukhethwa, kanye nokucaciswa nobukhulu be-forklift kanye neloli ye-hydraulic. Uma ukucaciswa nosayizi wethreyi yelabhulali enezinhlangothi ezintathu kungafani nemishini yakamuva, ukukhanya kuzomosha isikhala, futhi esindayo kuzonyusa izindleko zokuthenga.

*Iphalethi likasayizi ojwayelekile liyadingeka

Embonini, amaphalethi e-warehouse anezinhlangothi ezintathu ikakhulukazi ama-pallets ohlobo lwe-Chuan kanye namaphalethi ohlobo lwe-Tian. Ithreyi emise okwe-Chuan nayo inezinyawo eziphakeme, ama-chips nezindiza. Njengamanje, amaphalethi e-warehouse anezinhlangothi ezintathu asetshenziswa kakhulu ahlanganisa 1200 * 1000 * 150mm, 1200 * 1000 * 160mm, 1200 * 1200 * 15mm, 1200 * 1200 * 160mm nabanye osayizi abajwayelekile. Amaphalethi osayizi ojwayelekile anokuvumelana nezimo kangcono, futhi abushelelezi kakhulu futhi awajwayele ukungqubuzana ngesikhathi sokugcina, imali engenayo kanye nezokuthutha. Ngesikhathi esifanayo, i-pallet yesayizi evamile inganciphisa izindleko zokuthenga. Uma kuyithreyi yosayizi okhethekile, idinga ukwenziwa ngendlela oyifisayo. Amashalofu ayo asekelayo, izitaki, izithuthuthu, imigqa yokuhlanganisa kanye nama-forklift adinga ukufaniswa nayo. Izindleko zokunakekela kanye nezindleko zokushintsha esikhathini sakamuva ngokungangabazeki zizokwenyuka.

*Kudingeka ukuhlela ngokunengqondo inani lamaphalethi

I-automatic-dimensional warehouse inezinzuzo zokusebenza kahle okuphezulu, ukuminyana okuphezulu, ukusebenza kahle okuphezulu kanye nokuguquguquka okuphezulu. Ingakhiwa ezakhiweni ezinobukhulu obuhlukahlukene, ifanele amamodeli e-pallet epulasitiki ajwayelekile, futhi ingahlanganiswa kwezinye izinhlelo ukuze kuthuthukiswe inqubo yokugcina impahla. Ngokwezidingo zokukhipha impahla zendlu yempahla enezinhlangothi ezintathu kanye nokuminyana kwesitoreji sendlu yokugcina izinto, singacabangela ukukhethwa kwezindleko nokusebenza lapho sikhetha amaphalethi. Uma inani lama-pallets lihlelwe ngokunengqondo, izinga lokusebenzisa elimaphakathi lamaphalethi e-warehouse anezinhlangothi ezintathu lingafinyelela ngaphezu kwama-90%.

*Kudingeka ukuthi umthamo wokuthwala umthwalo wephalethi ufinyelele ezingeni

Abantu abaningi bangase bangazi umthamo wokuthwala umthwalo wephalethi lapho bethenga iphalethi lendlu yokugcina impahla enezinhlangothi ezintathu. Kufanele sazi ukuthi umthwalo oguquguqukayo, umthwalo we-static kanye nomthwalo weshelufu we-pallet uhlukile. Uma sikhetha i-pallet ye-warehouse enezinhlangothi ezintathu, sidinga ukucabangela umthwalo wezimpahla.

*Kudingeka ukuthi idigri yokugoba yethreyi ihlangabezane nezinga elijwayelekile

Lapho kusetshenziswa i-rack ku-pallet ye-warehouse enezinhlangothi ezintathu, idinga ukuhlolwa ukuguquguquka. Lapho isisindo esithile sezimpahla simbondelene ebusweni bephalethi, izinga lokugoba lizoba ngaphansi kuka-5%, ukuze i-pallet ingakhubazeki ngesikhathi sokusetshenziswa kwangempela.

*Kudingeka ukuthi ithreyi libe nokumelana okuqinile

Ithreyi yendlu yokugcina impahla enezinhlangothi ezintathu izoba nokumelana okuqinile. Ngokuvamile, kuyadingeka ukukhetha ithreyi elikhiqizwe futhi licutshungulwe ngezinto zokudla, ezimelana nomthelela wodlame, ukugqwala kwamakhemikhali kanye nezinga lokushisa nokushintsha komswakama. Uma i-tray yesitoreji esinezinhlangothi ezintathu esetshenziselwa isitoreji esibandayo, kuyadingeka futhi ukukhetha i-tray ekhethekile yokugcina amakhaza, ukuze impilo yesevisi yethreyi ibe yinde.

Ithini indawo yokugcina kanye nezimo zokusebenzisa zethreyi yelabhulali enezinhlangothi ezintathu ezizenzakalelayo?

Ukuze kuqinisekiswe ukusetshenziswa kwesikhathi eside nokuphephile kwethreyi yomtapo wolwazi enezinhlangothi ezintathu, kudingeka ukuthi kugcinwe kahle futhi kusetshenziswe ithreyi yomtapo wolwazi enezinhlangothi ezintathu ngokuya ngalezi zidingo ezilandelayo:

*Iphalethi lendlu yokugcina impahla enezinhlangothi ezintathu izovikelwa elangeni, ukuze ingabangeli ukuguga kwempahla yephalethi futhi ifinyeze impilo yesevisi.

*Kunqatshelwe ngokuphelele ukujikijela izimpahla kuphalethi wendlu yokugcina impahla enezinhlangothi ezintathu usuka endaweni ephakeme. Kudingekile ukunquma ngokunengqondo imodi yokupakisha yezimpahla ku-pallet, futhi izimpahla kufanele zibekwe ngokulinganayo. Ungawapakishi ngendlela emaphakathi noma ngokufihlekile.

*Kunqatshelwe ngokuphelele ukuphonsa i-pallet ye-warehouse enezinhlangothi ezintathu ukusuka endaweni ephakeme noma ukusuka endaweni ephansi ukuya endaweni ephakeme ukugwema ukuphuka nokuqhekeka kwe-pallet okubangelwa umthelela wobudlova.

*Lapho iloli ye-hydraulic kanye ne-forklift zisebenzisa i-pallet, ibanga phakathi kwamazinyo emfoloko lizoba banzi ngangokunokwenzeka emaphethelweni angaphandle we-inlet yemfoloko ye-pallet, futhi ukujula kwemfoloko kuzoba ngaphezu kuka-2/3 wokujula. i-pallet yonke. Ekusebenzeni kwangempela, qhubeka uye phambili futhi uhlehle futhi uye phezulu futhi phansi ngesivinini esifanayo ukuze ugweme ukulimala kwe-pallet kanye nokuwa kwezimpahla okubangelwa ukubhuleka kungazelelwe kanye nokuzungezisa kungazelelwe. Amazinyo emfoloko akufanele abe nomthelela ohlangothini lwethreyi ukugwema ukuphuka nokuqhekeka kwethreyi.

*Lapho ama-pallets enqwabelene, izimpahla zizopakishwa kancane ukuze zenze indawo engaphansi ye-pallet ngaphansi kwengcindezi efanayo, ukuze kugwenywe ukugqashuka kwephalethi okubangelwa ukuwohloka okukhulu kwephalethi.

*Lapho i-pallet ibekwe eshalofini, i-pallet izobekwa ngokuzinzile kugongolo lweshalofu. Ubude bephalethi buzoba bukhulu kunobubanzi obungaphandle beshelufu ngaphezu kwama-50mm. Ngesikhathi esifanayo, i-pallet yohlobo lwe-rack kufanele isetshenziswe. Umthamo wokuthwala uzonqunywa ngokuya ngesakhiwo seshalofu. Ukulayisha ngokweqile kunqatshelwe.

*Ithreyi yepayipi yensimbi eyakhelwe ngaphakathi izosetshenziswa endaweni eyomile.

I-Hegerls ayiyona nje kuphela inkampani yesevisi yokugcina impahla ehlanganisa i-R & D, ukukhiqiza, ukuthengisa kanye nesevisi, kodwa futhi umphakeli wethreyi ohlanganisa ukuthuthukiswa, ukukhiqizwa, ukuthengisa, ukuqashisa kanye nesevisi yamathreyi epulasitiki. Imikhiqizo yayo eyinhloko ihlanganisa: amathreyi e-warehouse anezinhlangothi ezintathu, amathreyi epulasitiki e-warehouse anezinhlangothi ezintathu, amathreyi epulasitiki e-auto-dimensional amathathu-dimensional, amathreyi okubumba, amathreyi e-RFID chip, kanye nokulayisha nokukhipha amathreyi amahhala. Imikhiqizo yayo isetshenziswa kabanzi ekudleni nasesiphuzweni, umanyolo wezokwelapha we-Chemical, Logistics, electronics, izingubo zokugqoka, ingilazi yokukhiqiza kanye nezinye izimboni zisetshenziswa kabanzi. Ngesikhathi esifanayo, ishalofu lokugcina i-haigris linikeza amakhasimende isisombululo esibanzi sokwakhiwa kwamaphrojekthi okugcina: ukuhlela nokuklama kwe-automated-dimensional arehouse kanye nesistimu ye-logistics; Ukukhethwa kwemishini nokuhlanganiswa kwesistimu; Isilinganiso sokutshalwa kwezimali kanye nokuhlaziywa kwezindleko; Ukusebenza kahle nezinga lokuphatha.

Isikhathi sokuthumela: Aug-15-2022