Idrayivu eshalofini isho ukugcinwa kwamaphalethi ngamunye ngamunye ukusuka ngaphakathi kuye ngaphandle. Isiteshi esifanayo sisetshenziselwa ukufinyelela kwe-forklift, futhi ukuminyana kwesitoreji kuhle kakhulu. Nokho, ngenxa yokungafinyeleleki kahle, akulula ukusebenzisa ukuphathwa kwe-FIFO. Njengoba i-forklift kufanele isebenze ngokucophelela lapho uhamba kuyo yonke i-rack, kungcono ukushayela ku-rack enezendlalelo ezi-4 namakholomu angu-3 kuya kwangu-5.

Shayela ekubunjweni kwama-rack

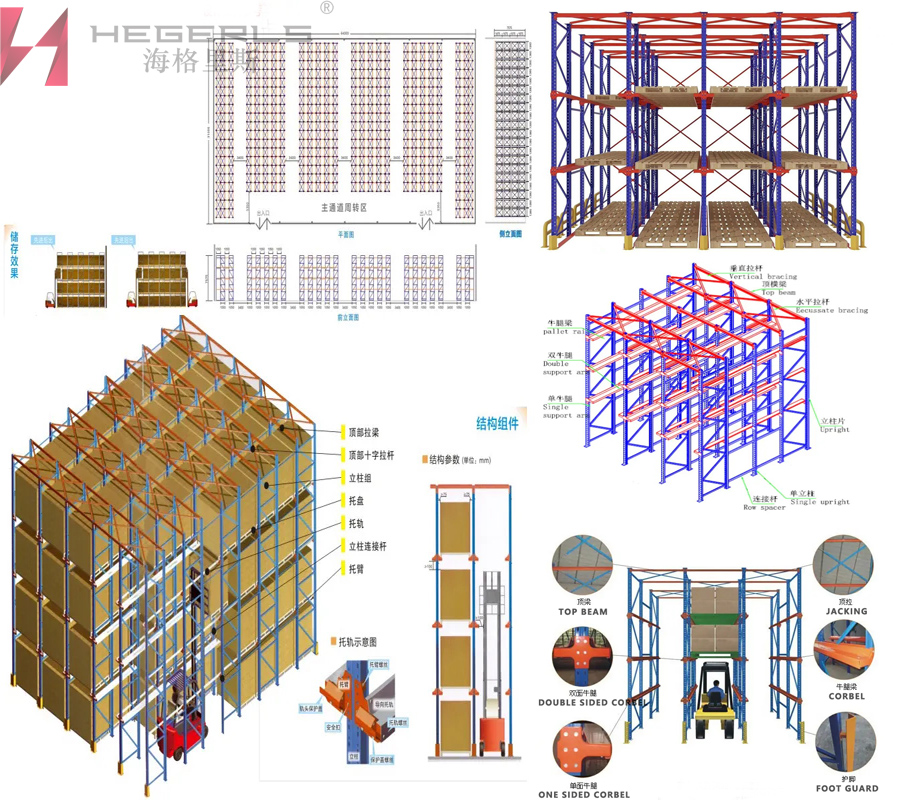

Izesekeli zedrayivu ku-rack zifaka: i-corbel (isixhumi esiyinhloko phakathi kwe-corbel nekholomu yokubeka, uhlangothi olulodwa nohlangothi oluphindwe kabili), i-corbel (ishalofu eliyinhloko lokusekela ukugcinwa kwempahla), i-top beam (isixhumi nesiqinisi se-rack ikholomu), ukudonsela phezulu (isixhumi nesiqinisi sekholomu yokubeka), ukudonsela emuva (isixhumi nesiqinisi sekholomu yokubeka, esetshenziselwa ukwakheka kwerack yendlela eyodwa), ukugada unyawo (ingxenye eyisivikelo engaphambili yerack) Amarayili onogada (izingxenye zokuzivikela zamashalofu lapho ama-forklift engena emgwaqeni), njll.

Ngokukhethekile, idrayivu ku-rack, eyaziwa nangokuthi i-corridor rack kanye ne-rack, iyisakhiwo se-rack yeminyango eminingi ehlanganisa imigqa eminingana yama-rack endabuko noma izakhiwo zekholomu ye-lattice ngendlela eqhubekayo ngaphandle kokuhlukaniswa kwesiteshi nokuqhubeka, futhi i-pallet igcinwa ku- i-cantilever beam kuyunithi futhi igcinwe endaweni ejulile; Lolu hlobo lweshalofu lunezici zomthamo omkhulu wokugcina wezimpahla ngevolumu yeyunithi ngayinye, futhi ilungele ukugcinwa nokusebenza kwesistimu yezinto ezinenqwaba enkulu, izinhlobo ezimbalwa nokugeleza okukhulu, njengeziphuzo, imikhiqizo yobisi, isiqandisi esisezingeni eliphansi. isitoreji, izinto zasendlini, amakhemikhali, izingubo zokugqoka, ugwayi nezinye izikhathi ezinezindleko eziphezulu zendawo yokugcina izinto, kodwa akufanelekile ukugcinwa kwezinto ezinde kakhulu noma ezinzima kakhulu; Uma kuqhathaniswa nesakhiwo seshelufu se-tray cross cross, izinga lokusebenzisa kahle isikhala sedrayivu eshalofini linganyuswa libe ngu-90% kakhulu, futhi izinga lokusebenzisa isayithi lingafinyelela ngaphezu kuka-60%, elingafinyelela ukuminyana okuphezulu kokulayisha. Enqubweni yangempela yokufaka isicelo, idrayivu eshalofini ingasetshenziswa futhi ihlanganiswe nezinye izakhiwo zamashalofu ezigaba eziningi ukuze kuhlangatshezwane ngokugcwele nezimfuneko zokulondoloza ezehlukene zesayithi yekhasimende.

Ngakho-ke, siyithenga kanjani idrayivu eshalofini ngaphambi kokuyisebenzisa nsuku zonke? Manje, asilandele umkhiqizi weshalofu lika-Higelis ukuze sithole!

Ukuthengwa kwedrayivu emashalofini kudinga ukuqonda okucacile kwe-pallet unitization yezinto ezigciniwe

Isakhiwo kanye nosayizi we-drive eshalofini kunqunywa izinto zokugcina, izinto zokuphatha kanye nosayizi weyunithi ye-pallet; Ngenxa yobuningi besitoreji esikhulu kanye nokusebenza kahle okuphezulu kwe-turnover yedrayivu endaweni yokugcina ishalofu, isakhiwo sensimbi seshalofu siseduze nokusebenza kanye neziteshi zokugcina. Uma kuqhathaniswa nezinye izinhlobo zamashalofu, kukhona ukucaciswa okuningiliziwe kanye nezidingo zekhwalithi ephezulu zeyunithi yephalethi nephalethi. Kudingekile ukwenza ukukhetha okuphumelelayo ngokuvumelana nezici zamandla we-pallet, ikakhulukazi kuma-pallets amade, umthwalo omile futhi oguquguqukayo we-pallet kufanele uhlolwe Umthwalo emashalofini kanye nendlela izimpahla ezibekwe ngayo kuma-pallets; Ngesikhathi esifanayo, ishalofu lalesi sigaba linezidingo eziphezulu ekufakweni kweyunithi yezimpahla, ukuze kuncishiswe izinga lomonakalo wezimpahla ezigciniwe futhi kuthuthukiswe ukusebenza kahle nokuphepha kokuthunyelwa; Izimpahla ezihlanganisiwe ze-pallet akufanele zibe zikhulu kakhulu noma zibe nzima kakhulu. Ngokuvamile, isisindo kufanele silawulwe ngaphakathi kwe-1600KG, futhi ubude be-pallet akufanele bube ngaphezu kwe-1.5M. Ukwengeza, ngezigaba zokupakishwa ezihlanganisiwe zezimpahla ezigciniwe, umthwalo osindayo kanye nezimpahla ezinkulu zokuphakama kwephansi kufanele zigcinwe endaweni yokugcina ephansi kakhulu yedrayivu esakhiweni seshalofu ngangokunokwenzeka, okunganciphisa ngempumelelo isikhungo sokugcina amandla adonsela phansi eshalofini. uhlelo futhi uthuthukise ukugcinwa nokuzinza kwesistimu.

Ukuthengwa kwedrayivu kusakhiwo se-lattice seshalofu esiqondile futhi kuncike ekwakhekeni kwekholomu ye-lattice

Isakhiwo sekholomu ye-lattice esaklanywa, sakhiqizwa futhi sakhiqizwa umkhiqizi weshalofu we-Higelis futhi yisakhiwo esivame kakhulu ekushayeleni kwesakhiwo seshalofu. Ikakhulukazi yakhiwe ilunga lekholomu (ikholomu yohlaka) kanye nelungu lewebhu (ibrace ephambanayo kanye nebrace diagonal). Umlenze wekholomu ngokuvamile wamukela ikholomu yensimbi yesigaba esinezimbotshana ezinezindonga ezilinganayo ezilinganayo. Ilungu lewebhu livame ukusebenzisa insimbi ebandayo yesigaba esimise okwe-C. Isitho sekholomu kanye nelungu lewebhu kuxhunywe ngamabhawodi ukuze kwakheke ukwakheka kwe-diagonal yokulecing yebha. Ukucindezela kwekholomu yefreyimu kungenxa yesiphambano I-diagonal braces ihlanganyela ingxenye yesakhiwo futhi iyancipha kancane. Isakhiwo sonke siphephile ngaphandle kokucabangela imiphumela emihle yama-braces transverse kanye nama-diagonal braces; Isakhiwo esijwayelekile sekholomu siyingxenye yekholomu yensimbi yesigaba esibandayo esakhiwe ngendlela ebandayo enezindonga ezincane ezinembobo. Lapho ithwala umthamo womthwalo, ijwayele ukugoba kanye ne-torsional buckling, okunciphisa umthamo wokuthwala. Ungakwazi ukwengeza ama-battens ohlangothini oluvulekile ukuze ulenze eduze nesigaba esivaliwe, esingathuthukisa kakhulu umthamo wayo wokuzala. Ukuzinza kokugoba kwe-XX kwalolu hlobo lwengxenye kunquma ngokuqondile umthamo wokuthwala nokuzinza kwesakhiwo sedrayivu eshalofini. Ngokufanayo, lesi sakhiwo sekholomu ye-lattice futhi siyikholomu eseceleni yesakhiwo sephothali yedrayivu eshalofini. Ngenxa yokuthi ukuqina okugobayo kanye nokuqina kwe-torsional kwamalungu esakhiwo sephothali kuncane, ukuqina okuphelele kwesakhiwo akunamandla. Ukuphakama kokuphakama, ukwehla kwezinga lokuthwala, kanye nekhono lokumelana nokugoba kanye ne-torsional buckling kuzoncipha kakhulu. Imingcele yobude bengalo ye-cantilever kanye nesisindo sethreyi elithwalayo abadlali abaqondile abasebenzisa i-torque egobayo esakhiweni sekholomu ye-lattice, I-torque eyengeziwe yokugoba ekhiqizwe kanye nobude be-cantilever ithinta ukugoba namandla okugoqa wekholomu yokubeka.

Njengamanje, ukuhlaziywa kohlaka lwesakhiwo sesistimu kushintshaniswa ukubalwa kwamandla, ukuqina kanye nokuzinza kwekholomu ye-lattice ekwakhiweni kwedrayivu eshalofini. Ngenxa yokuthi ikholomu ye-lattice ngokuvamile yakhiwa izingxenye ezincane nezincane, ukuqina nokuzinza kwesakhiwo sekholomu kudrayivu esakhiweni seshalofu kuthinteka kakhulu isilinganiso salo somzimba omncane, ukuqina kwayo kwesakhiwo kubuthakathaka, futhi zimbalwa izindlela zokuqiniswa kwesakhiwo ezingase zikwazi ukuqiniswa. kufezeke, Kunzima futhi ukufeza. Njengamanje, imakethe ithuthukisa isiteshi sokusebenza ngokusebenzisa amaloli e-WAP ashuthayo ukuze athathele indawo yokungena nokuphuma kwemodi yokusebenza yomhubhe yezinye izinto zokubamba ezifana nama-forklift, futhi ingasiza ukuqiniswa kwenduku evundlile yekholomu yefreyimu engxenyeni esebenzayo engezansi kwesitoreji. indawo, engathuthukisa kakhulu isilinganiso sobuncane bekholomu yozimele; Noma endaweni engaphakathi kakhulu yempahla yomgwaqo wokungena nokuphuma, idizayini yedrayivu esakhiweni seshalofu ithuthukiswa ngesakhiwo esijwayelekile seshalofu le-pallet, ukuze kuthuthukiswe umthamo wokuthwala nokuzinza kwesakhiwo seshalofu sisonke, okuzoba enye yezindlela eziyinhloko zokuthuthukisa idrayivu esakhiweni seshalofu esikhathini esizayo.

Isikhathi sokuthumela: Sep-19-2022